diamond cutter diamond tool CBN Professional processing of high hardness materials Double head

- Category: >>>

- Supplier: Dongguan Cheng Zhen Electronic Technology Co. Ltd.Dongguan Ltd.

Share on (1601299440905):

Product Overview

Description

Recommend Products

Real customer feedback

Products Description

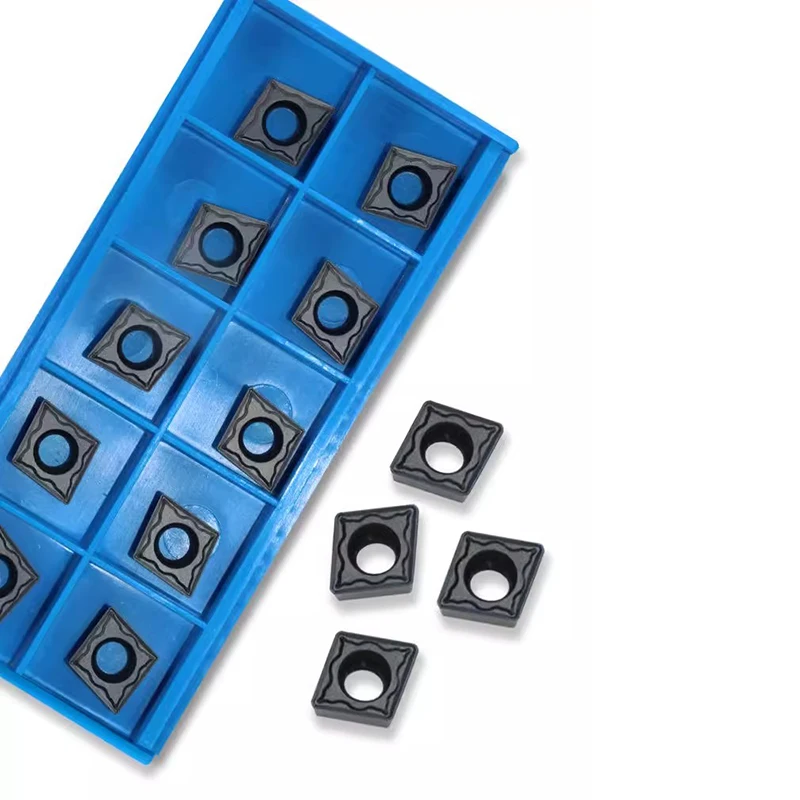

CBN Tipped Turning Inserts TNGA Brazing PCBN Insert has a small and exquisite cutting head, high wear resistance, and can withstand larger cutting forces. Vacuum welding is now used to replace the original high-frequency welding, and overall welding is used to replace the original single-sided welding. The advanced processing technology improves the bonding strength between the cutter head and the cutter body. Compared with the previous integrated composite blade, it avoids the processing problems caused by the delamination of the CBN layer. Because the blade can be machined on both sides with the integrated welding technology to increase the cutting edge, the tool utilization is improved.

Company's Main Products:

Suitable for CNC machinery turning tools, thread blades, grooving cutting blades, small parts processing, milling tools, integral carbide cutting tools, hole processing tools, Chinese manufacturing cutting tools and other alloy tools.

CBN carbide insert for cast iron machining and chilled hardened steel | ||||||||

Name | CBN inserts | |||||||

Carbide inserts material | Carbide + CBN | |||||||

Cutting fluid | Dry cut/wet cut | |||||||

Application material | High speed continuous cutting of P & M workpicces. | |||||||

OEM & ODM | Acceptable | |||||||

Delivery time | 2-3 days after payment | |||||||

Detailed Images

Product Name | CHAJANE PCBN insert |

Material | PCBN+Carbide |

Hardness | 92HRC |

Machining model | Rough/Semi-finishing/Finishing |

Precision | High precision |

Use | External Turning Tool |

Application | CNC Process |

Advantage | High Wear Resistance |

Workpiece | Cast iron/Hardened steel/Cemented steel, etc |

Feature | Efficient processing, reduce scrap rate, extend tool life |

CBN Tipped Brazed Coating Insert | ||||||||

Grade | Machining model | Applicable industry | Workpiece material | Cutting speed Vc(m/min) | ||||

FBK7520 C07 | Finishing | Brake disc Gear | Gray cast iron Powder metallurgy | 600-1200 90-200 | ||||

FBK9540 C06 | Finishing | Gear Bearing | Hardened steel | 180-300 | ||||

FBK9550 C06 | Finishing | Gear Bearing | Bearing steel Cemented steel | 100-175 | ||||

FBK9560 C06 | Finishing | Gear Bearing | Cemented steel | 100-200 | ||||

CBN Brazed Insert | ||||||||

Grade | Machining model | Applicable industry | Workpiece material | |||||

FBV7200 | Finishing | Brake disc Brake drum Parts of compressor | Gray cast iron | |||||

FBV5800 | Finishing | Gear Bearing Parts of compressor | Hardened steele Gray cast iron | |||||

FBV7200 C07 | Finishing | Brake disc Brake drum Parts of compressor | Gray cast iron | |||||

FBV7200 C07 | Finishing | Gear Bearing Parts of compressor | Hardened steele Gray cast iron | |||||

CBN Solid Insert | ||||||||

Grade | Machining model | Machining model | Workpiece material | |||||

FBN7600 | Rough/ Semi-finishing | Rol, slurry pump Brake disc Brake drum Roling mortar wall Parts of compressor | High nickel-chromium High hardness aloy cast iron High speed steel Gray cast iron High manganese steel | |||||

FBN9500 | Rough/ Semi-finishing | Gear Bearing Roling mortar wall Parts of compressor | Hardened steel Surface overlaying material | |||||

FBN9500 CO6 | Rough/ Semi-finishing | Gear Bearing Mining machinery Coal mine machinery | Hardened steel Cemented steel Surface overlaying material | |||||

Plant strength

Chengzhen Precision Tools Co., Ltd. is the largest tungsten carbide production base in China. We manufacture end mills and drills with 15 years of experience, continuous research and development, as well as professional production and quality control, to ensure that tungsten Carbide precision tools deliver the highest quality products in a short time.

Chengzhen Precision Tools Co., Ltd. has several offline stores in various regions of China, welcome to visit.

About us

Customer Service

We Recommend

New Arrivals

New products from manufacturers at wholesale prices