What's the LED backlight application ?

A:

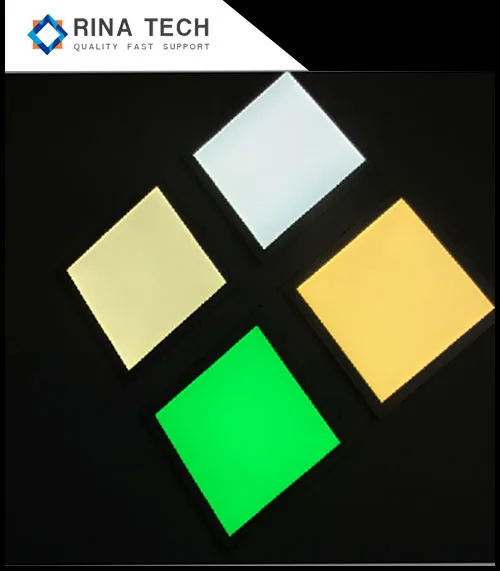

LED backlighting is commonly used in various displays and lighting applications due to its energy efficiency, long lifespan, and ability to produce bright, vibrant colors. Here are some key applications of LED backlighting:

1. Televisions: LED backlighting is widely used in LCD TVs to enhance picture quality by providing brightness and contrast. It is often found in various types of LED TVs, including edge-lit and full-array backlit models.

2. Computer Monitors: Many modern computer monitors utilize LED backlighting for improved image quality and energy efficiency compared to traditional CCFL-backlit displays.

3. Smartphones and Tablets: LED backlighting is applied in liquid crystal displays (LCDs) used in smartphones and tablets, contributing to thinner device designs and enhanced visual performance.

4. LCD Displays: Various devices, including digital signage, kiosks, and automotive displays, use LED backlighting to ensure visibility in different lighting conditions.

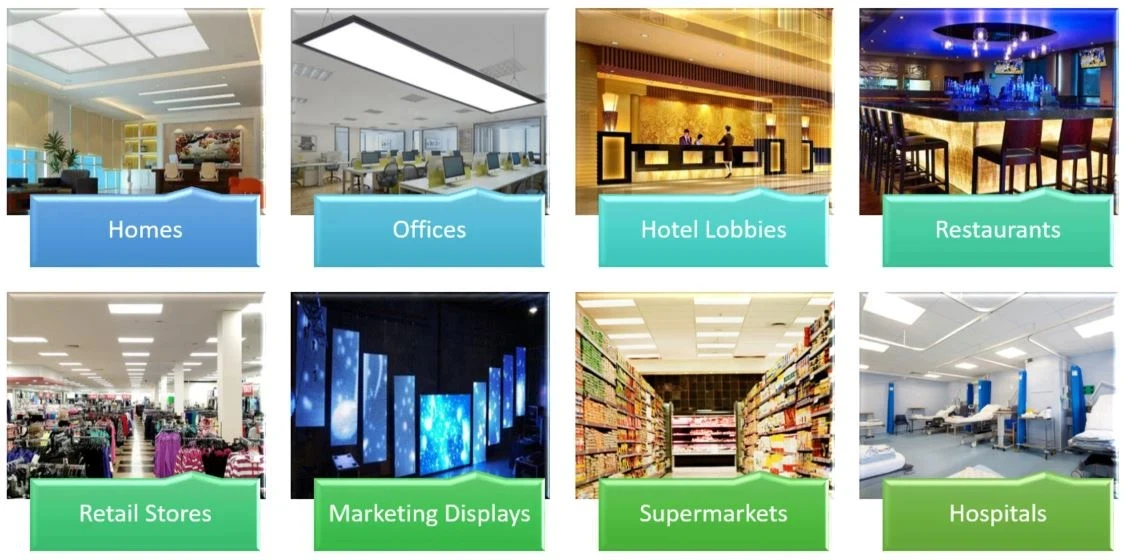

5. Lighting Fixtures: LEDs are used in panel lights, troffers, and downlights to provide efficient and adjustable ambient lighting in residential and commercial spaces.

6. Specialty Lighting: LED backlighting is used in applications such as architectural lighting, retail displays, and accent lighting to create visually appealing environments.

7. Photography and Video: LED panels and light boxes, which use LED backlighting, are employed in photography and videography for additional lighting.

8. Medical Devices: Many medical displays, including monitors and imaging devices, use LED backlighting for clarity and accuracy of vital information.

9. Gaming Consoles: LED backlighting is utilized in gaming monitors and VR headsets to enhance the gaming experience with vibrant colors and better contrast.

10. Consumer Appliances: Appliances like refrigerators and ovens may feature LED backlit displays for user interfaces that are easy to read.

LED backlighting technology continues to evolve, with advancements like local dimming and color-changing capabilities enhancing their applications across various industries.