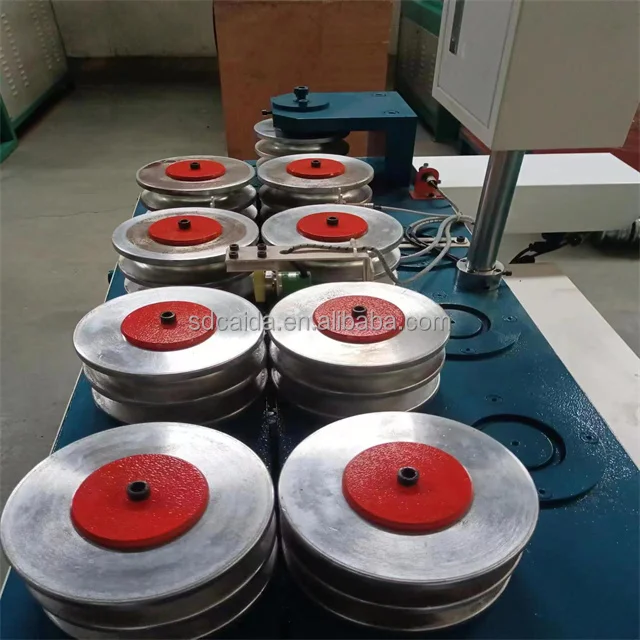

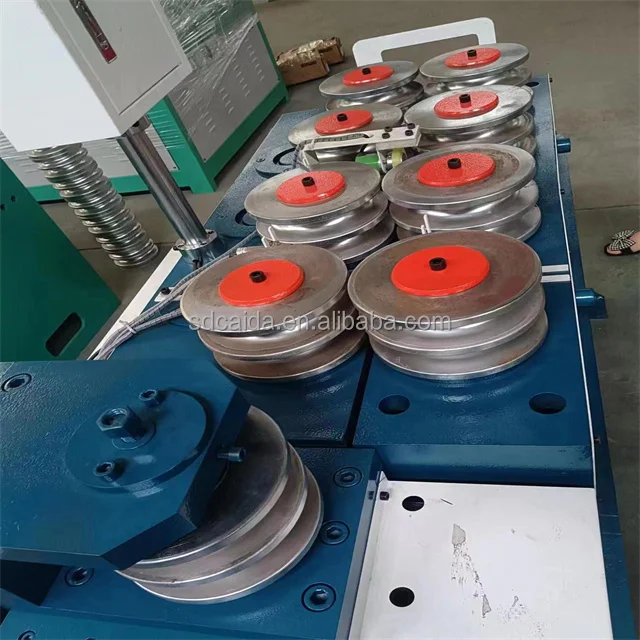

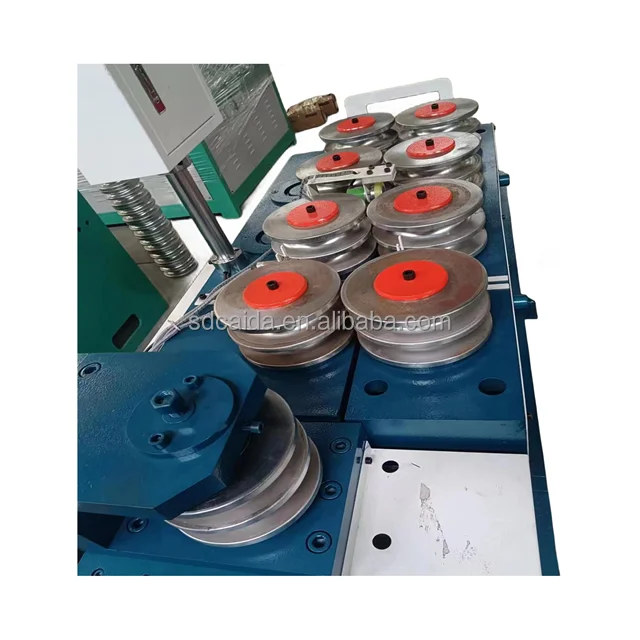

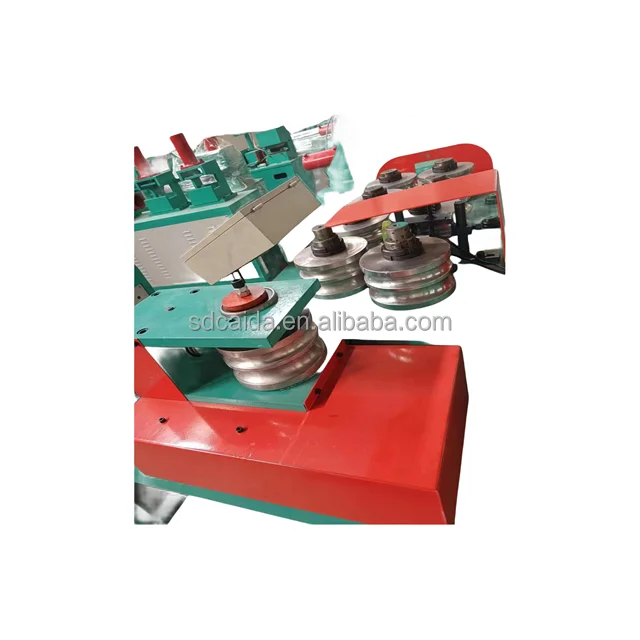

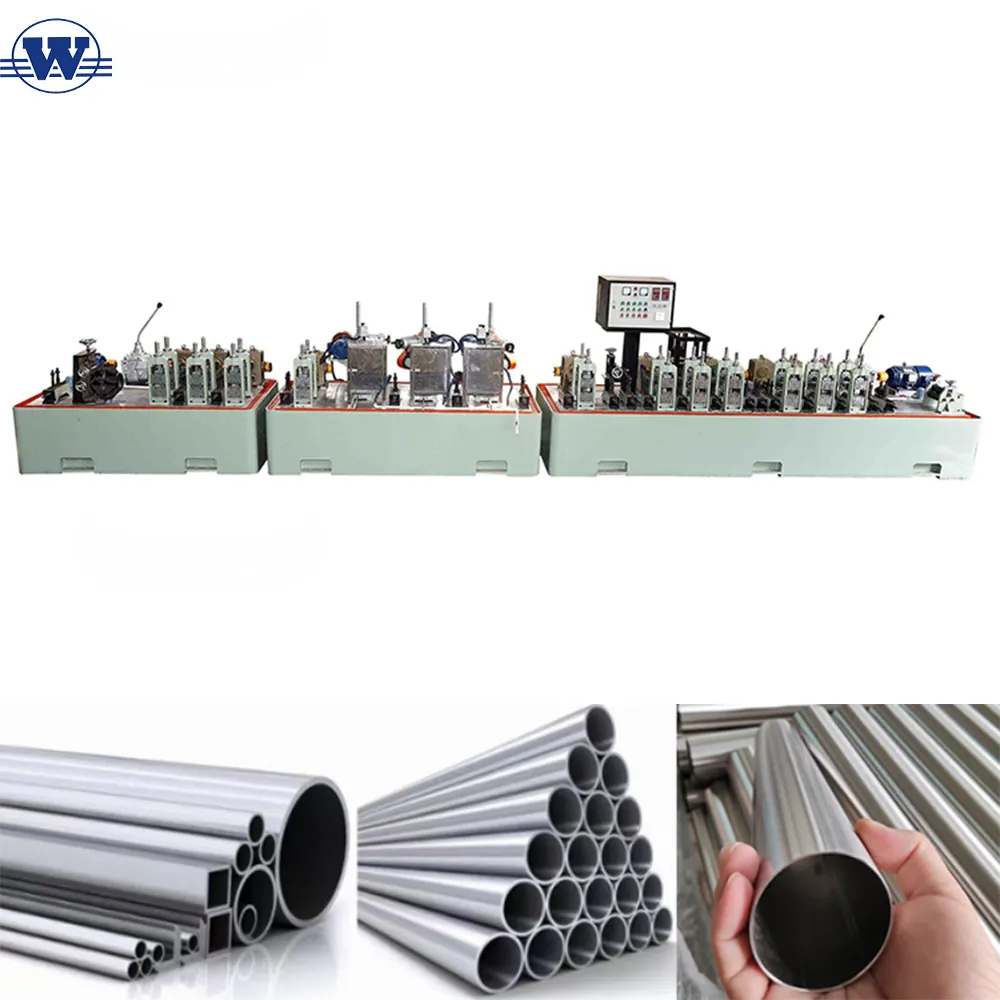

Servo rounding machine stainless steel pipe round pipe bending machine vegetable greenhouse metal home arc bending machine

- Category: >>>

- Supplier: Shandong Caida Cnc Machinery Co. Ltd.Shandong Ltd.

Share on (1601301462204):

Product Overview

Description

Product Description

Specification

item | value |

Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

Showroom Location | Egypt, Italy, Saudi Arabia, Russia, Uzbekistan |

Video outgoing-inspection | ok |

Machinery Test Report | Provided |

Marketing Type | Hot Product 2019 |

Warranty of core components | 1 Year |

Core Components | PLC, Engine, Gear |

Condition | New |

Type | PIPE BENDER |

Pipe Material | Iron pipe, copper pipe, aluminum pipe, stainless steel pipe |

Application | Round pipe bending machine |

Production Capacity | 30m |

Place of Origin | China |

Hebei | |

Brand Name | caida |

Voltage | |

Power | 5.5kw |

Dimension(L*W*H) | 1.681.6*1.5m |

Weight | 1500kg |

Warranty | 1 Year |

Key Selling Points | Easy to Operate |

Product name | Vegetable greenhouse pipe bende |

Shaft diameter | 70mm |

Molding line number | 9/11/13 rounds Bearing steel |

Steel plate thickness | 50 mm |

Packing & Delivery

and shafts are covered with anti-rust oil. c.PLC control system and motor pump are packed with waterproof paper and plastic film.

d.Spare parts in a carton box. e.Manual decoiler was nude packing. f.The output-table put into a carton box. g.If the machine is

too long, we will divide it into two parts and pack them in one package with steel wire. h.Fit for ocean shipping.

d.Spare parts in a carton box. e.Manual decoiler was nude packing. f.The output-table put into a carton box. g.If the machine is

too long, we will divide it into two parts and pack them in one package with steel wire. h.Fit for ocean shipping.

Company Profile

Shandong Caida CNC Machinery Co., Ltd. It is a manufacturer dedicated to the design and manufacture of different types of cold rolling machines. We are a long-established factory and have been engaged in the design and manufacture of roller presses since 2013. The machines we can produce include: roof tile making machine, cz plin making machine, light steel keel making machine, metal embossing machine, door system forming machine, ceiling system forming machine, high-frequency tube welding machine, longitudinal cutting line, fixed-length cutting line, shelf system forming machine, floor forming machine, punching machine, rolling door rolling molding machine, liquid Press, shearing machine, bending machine, colored stone tile production line, etc.

On this basis, Caida has also developed a high-speed multi-functional metal composite plate forming machine according to international trends and market demand. This research and development uses metal materials as the substrate, which can be combined with up to 8 layers of materials, usually composed of anti-aging transparent layer + aluminum foil + polymer film + substrate + polymer film + foam layer + aluminum foil + anti-corrosion layer. Compared with ordinary metal roof tiles, this new material has the advantages of sound insulation and noise reduction, anti-condensation and rain leakage, acid and alkali resistance and corrosion resistance. After five high-temperature thermal bonding processes and two high-strength anti-aging glue and processes, this process is more time-saving and labor-saving and has a lower manufacturing cost than the ordinary EPS/PU sandwich plate processing process. Produce printing plates with a longer life. On the basis of this new material, we not only have equipment to manufacture new materials, but also optimize the existing roof tiles and other equipment, which can process ordinary PPGI metal materials and new composite materials. The finished product is of high quality and easy to use. There will be no bending or upturning.

Our company has a professional production line and sales team, which instills the concept of "time is money and quality is life" into every employee's heart. While improving production efficiency and shortening the delivery period, the quality of the equipment has also been controlled. All equipment has been tested before shipment, and the problematic equipment will not be delivered to the customer. We have rich export experience and understand the different needs of customers in developing and developed countries. Over the years, we have provided many customers with satisfactory equipment solutions. Today, our equipment has been exported to more than 150 countries around the world and has established a long-term and stable cooperative relationship with customers, which has won unanimous praise from customers.

On this basis, Caida has also developed a high-speed multi-functional metal composite plate forming machine according to international trends and market demand. This research and development uses metal materials as the substrate, which can be combined with up to 8 layers of materials, usually composed of anti-aging transparent layer + aluminum foil + polymer film + substrate + polymer film + foam layer + aluminum foil + anti-corrosion layer. Compared with ordinary metal roof tiles, this new material has the advantages of sound insulation and noise reduction, anti-condensation and rain leakage, acid and alkali resistance and corrosion resistance. After five high-temperature thermal bonding processes and two high-strength anti-aging glue and processes, this process is more time-saving and labor-saving and has a lower manufacturing cost than the ordinary EPS/PU sandwich plate processing process. Produce printing plates with a longer life. On the basis of this new material, we not only have equipment to manufacture new materials, but also optimize the existing roof tiles and other equipment, which can process ordinary PPGI metal materials and new composite materials. The finished product is of high quality and easy to use. There will be no bending or upturning.

Our company has a professional production line and sales team, which instills the concept of "time is money and quality is life" into every employee's heart. While improving production efficiency and shortening the delivery period, the quality of the equipment has also been controlled. All equipment has been tested before shipment, and the problematic equipment will not be delivered to the customer. We have rich export experience and understand the different needs of customers in developing and developed countries. Over the years, we have provided many customers with satisfactory equipment solutions. Today, our equipment has been exported to more than 150 countries around the world and has established a long-term and stable cooperative relationship with customers, which has won unanimous praise from customers.

FAQ

1. who are we?

We are based in Shandong, China, start from 2023,sell to Southern Europe(14.00%),Western Europe(13.00%),Oceania(12.00%),Eastern Europe(11.00%),Domestic Market(10.00%),Northern Europe(9.00%),Eastern Asia(8.00%),Africa(7.00%),South America(6.00%),South Asia(5.00%),Central America(4.00%),Mid East(3.00%),Southeast Asia(2.00%),North America(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Punching machine,Shutter Door RoII Forming Machine,RoofIng sheet RoII Forming Machine,Metal embossing machine,Hydraulic press

4. why should you buy from us not from other suppliers?

Shandong Caida CNC Machinery Co., Ltd. is a manufacturer dedicated to the design and manufacture of different types of cold bending machines. We are a factory with a long history. The machines we can produce include: punching machine, bending machine, shea

5. what services can we provide?

Accepted Delivery Terms: null;

Accepted Payment Currency:null;

Accepted Payment Type: null;

Language Spoken:null

We are based in Shandong, China, start from 2023,sell to Southern Europe(14.00%),Western Europe(13.00%),Oceania(12.00%),Eastern Europe(11.00%),Domestic Market(10.00%),Northern Europe(9.00%),Eastern Asia(8.00%),Africa(7.00%),South America(6.00%),South Asia(5.00%),Central America(4.00%),Mid East(3.00%),Southeast Asia(2.00%),North America(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Punching machine,Shutter Door RoII Forming Machine,RoofIng sheet RoII Forming Machine,Metal embossing machine,Hydraulic press

4. why should you buy from us not from other suppliers?

Shandong Caida CNC Machinery Co., Ltd. is a manufacturer dedicated to the design and manufacture of different types of cold bending machines. We are a factory with a long history. The machines we can produce include: punching machine, bending machine, shea

5. what services can we provide?

Accepted Delivery Terms: null;

Accepted Payment Currency:null;

Accepted Payment Type: null;

Language Spoken:null

We Recommend

machinery production vertical pipe making machine for concrete pipe

US $25000-$26000

The Steel Metal Square Pipe Tube Roll Making Machine For Tube Making Machine

US $150000-$180000

New Arrivals

New products from manufacturers at wholesale prices