High Performance Wafer Type Double Door Check Valve ANSI Class125/150 DIN BS PN16

- Category: >>>

- Supplier: Zhangguo Industry Co. Ltd.Zhangguo Ltd.

Share on (1601305373366):

Product Overview

Description

Products Description

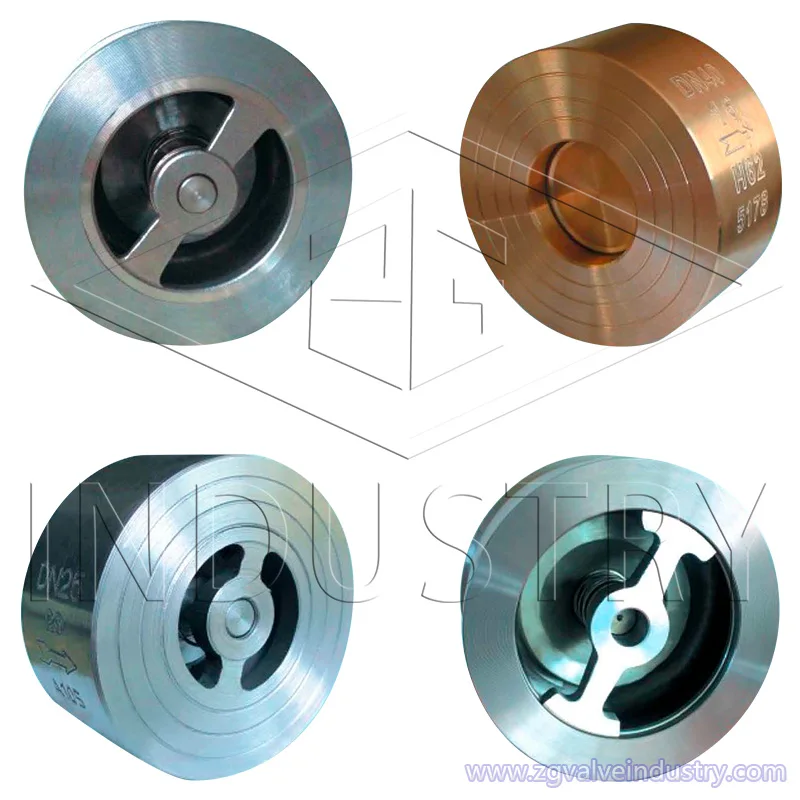

ANSI Class125/150 DIN BS PN16 Wafer Type Double Door Check Valve

Check Valves are the valves of stopping the fluid from backflow. The disc can be opened by the pressure of fluid. And then the fluid runs from the inlet to the outlet side. When the pressure of inlet is less than outlet, the disc can be cloased automatically and stop the fluid from backflow.

The swing check valve adopts a built-in rocker swing structure. All the opening and closing parts of the valve are installed inside the valve body and do not penetrate the valve body. Except for the sealing gasket and sealing ring at the middle flange, the whole There is no leakage point, preventing the possibility of valve leakage. The swing arm of the swing check valve adopts a spherical connection structure at the connection between the rocker arm and the valve flap, so that the valve flap has a certain degree of freedom within the range of 360 degrees, and there is an appropriate micro position compensation.

It is suitable for clean media, not for media containing solid particles and high viscosity.

Wafer Swing Check Valve Features:

1. The structure length is short, and its structure length is only 1/4~1/8 of the traditional flange check valve;

2. Small size and light weight, its weight is only 1/4~1/20 of the traditional flange check valve;

3. The valve flap closes quickly and the water hammer pressure is small;

4. Both horizontal pipes and vertical pipes can be used, and the installation is convenient;

5. The flow channel is unobstructed and the fluid resistance is small;

6. Sensitive action and good sealing performance;

7. The valve disc has short stroke and small closing impact;

8. The overall structure, simple and compact, beautiful appearance;

9. Long service life and high reliability.

Field of Application:

Size Range: 2“-24”/DN50-DN900

Working Temperature: ≤120°C

Allowable Operating Pressure: PN10/PN16/125LB/150LB

Check Valve for use inpetrochemical industry, Chemical,Fiber Textiles, plastic, paper making, power industry, steel, rubber and gas systems.

Technical Specification:

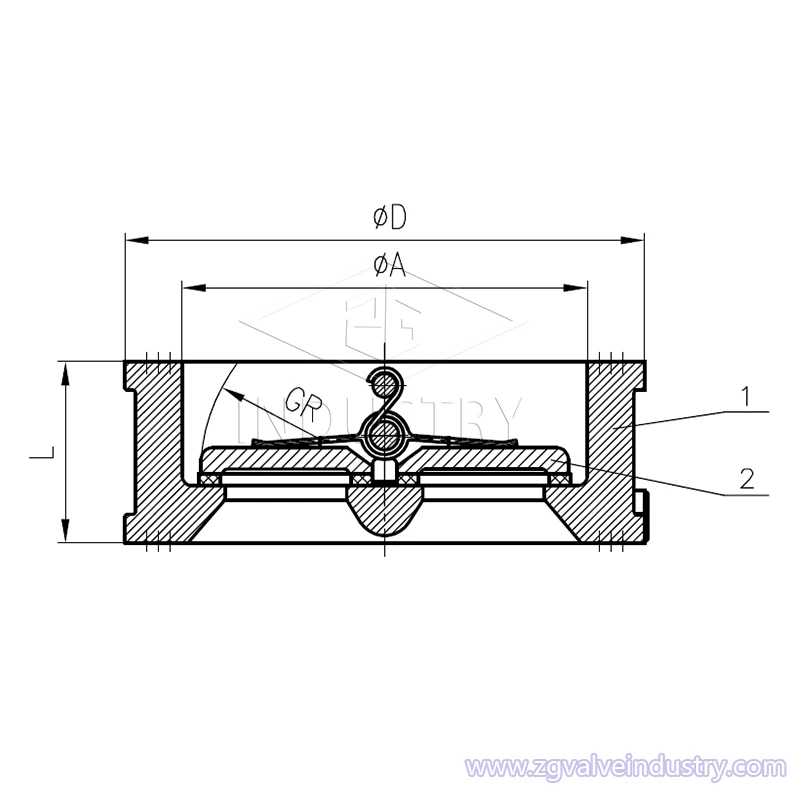

1. Face to Face Dimension EN558-1

2. End Flange Dimension ANSI/DIN/BS

The swing check valve adopts a built-in rocker swing structure. All the opening and closing parts of the valve are installed inside the valve body and do not penetrate the valve body. Except for the sealing gasket and sealing ring at the middle flange, the whole There is no leakage point, preventing the possibility of valve leakage. The swing arm of the swing check valve adopts a spherical connection structure at the connection between the rocker arm and the valve flap, so that the valve flap has a certain degree of freedom within the range of 360 degrees, and there is an appropriate micro position compensation.

It is suitable for clean media, not for media containing solid particles and high viscosity.

Wafer Swing Check Valve Features:

1. The structure length is short, and its structure length is only 1/4~1/8 of the traditional flange check valve;

2. Small size and light weight, its weight is only 1/4~1/20 of the traditional flange check valve;

3. The valve flap closes quickly and the water hammer pressure is small;

4. Both horizontal pipes and vertical pipes can be used, and the installation is convenient;

5. The flow channel is unobstructed and the fluid resistance is small;

6. Sensitive action and good sealing performance;

7. The valve disc has short stroke and small closing impact;

8. The overall structure, simple and compact, beautiful appearance;

9. Long service life and high reliability.

Field of Application:

Size Range: 2“-24”/DN50-DN900

Working Temperature: ≤120°C

Allowable Operating Pressure: PN10/PN16/125LB/150LB

Check Valve for use inpetrochemical industry, Chemical,Fiber Textiles, plastic, paper making, power industry, steel, rubber and gas systems.

Technical Specification:

1. Face to Face Dimension EN558-1

2. End Flange Dimension ANSI/DIN/BS

Description

Check Valves are the valves of stopping the fluid from backflow. The disc can be opened by the pressure of fluid. And then the fluid runs from the inlet to the outlet side. When the pressure of inlet is less than outlet, the disc can be cloased automatically and stop the fluid from backflow.

1. Lifting steel check valve has the advantages of simple structure, reliable action and convenient maintenance. It is widely used in purification equipment, petroleum, chemical industry, metallurgy, electric power, textile and other production processes.

2. When the medium flows into the valve body from the direction indicated by the arrow of the valve body, the pressure of the medium acts on the valve clack to produce an upward thrust. When the medium thrust is greater than the weight of the valve clack, the valve opens. When the pressure of the medium behind the valve acts on the disc and the weight of the disc itself is greater than the force exerted on the disc by the pressure in front of the valve, the valve is closed to prevent the medium from flowing back.

3. The function of the lift check valve is to only allow the medium to flow in one direction and prevent the reverse flow. Moreover, the valve clack can be made of metal, or can be inlaid with leather, rubber, or synthetic covering, which can be selected flexibly.

4. The valve disc of the lift check valve is seated on the sealing surface of the valve seat on the valve body. Except that the disc can be lifted and lowered freely, the rest is like a shut-off valve. The fluid pressure lifts the disc from the sealing surface of the valve seat, and the backflow of the medium causes the disc to fall back to the valve seat and cut off the flow.

It is suitable for clean media, not for media containing solid particles and high viscosity.

Wafer Single Flap Lift Check Valve Features:

1.Water hammer pressure:

very small, short disc stroke, spring assisted closing, fast valve closing speed

2. Dimensions and weight:

The structure length of the wafer single flap lift check valve is only 1/4~1/8 of the flange lift check valve, and the weight is only 1/7~1/20 of the flange lift check valve.

The structure is very short in length, small in size, and light in weight, which brings great convenience to the installation, transportation, storage and pipeline arrangement of the valve, and can save a lot of materials and reduce the cost.

3. Fluid resistance

Larger, the fluid resistance coefficient is 2.8~6.4

Still smaller than the fluid resistance coefficient of the flange lift check valve (6~12)

4. Installation method

It can be installed horizontally or vertically, with light weight and easy installation.

5. Cracking pressure

Very small, the disc can fully open the valve under a small pressure difference.

6. Reliability

The valve is a whole structure, simple and compact, the impact force is small when the valve is closed, the water hammer pressure is very small, the valve life is long, and the reliability is high.

Field of Application:

Size Range: 1/2"~8" DN15-DN200

Working Pressure: PN10~PN100

Working Temperature: -196~540°C

Application for: By selecting different materials, it can be applied to a variety of media such as water, steam, oil, nitric acid, acetic acid, strong oxidizing media, and urea.

Technical Specification:

Design standard: JB/T8937

Face to Face dimension: JB/T8937

Connection flange: JB/T74-90, GB/T13402, GB/T9112-9124, HG/T20592~20635

Pressure temperature rating: JB/T74, GB/T9124, HG20604~20625

Test standard: JB/T9092

Design Features:

Check Valves are the valves of stopping the fluid from backflow. The disc can be opened by the pressure of fluid. And then the fluid runs from the inlet to the outlet side. When the pressure of inlet is less than outlet, the disc can be cloased automatically and stop the fluid from backflow.

1. Lifting steel check valve has the advantages of simple structure, reliable action and convenient maintenance. It is widely used in purification equipment, petroleum, chemical industry, metallurgy, electric power, textile and other production processes.

2. When the medium flows into the valve body from the direction indicated by the arrow of the valve body, the pressure of the medium acts on the valve clack to produce an upward thrust. When the medium thrust is greater than the weight of the valve clack, the valve opens. When the pressure of the medium behind the valve acts on the disc and the weight of the disc itself is greater than the force exerted on the disc by the pressure in front of the valve, the valve is closed to prevent the medium from flowing back.

3. The function of the lift check valve is to only allow the medium to flow in one direction and prevent the reverse flow. Moreover, the valve clack can be made of metal, or can be inlaid with leather, rubber, or synthetic covering, which can be selected flexibly.

4. The valve disc of the lift check valve is seated on the sealing surface of the valve seat on the valve body. Except that the disc can be lifted and lowered freely, the rest is like a shut-off valve. The fluid pressure lifts the disc from the sealing surface of the valve seat, and the backflow of the medium causes the disc to fall back to the valve seat and cut off the flow.

It is suitable for clean media, not for media containing solid particles and high viscosity.

Wafer Single Flap Lift Check Valve Features:

1.Water hammer pressure:

very small, short disc stroke, spring assisted closing, fast valve closing speed

2. Dimensions and weight:

The structure length of the wafer single flap lift check valve is only 1/4~1/8 of the flange lift check valve, and the weight is only 1/7~1/20 of the flange lift check valve.

The structure is very short in length, small in size, and light in weight, which brings great convenience to the installation, transportation, storage and pipeline arrangement of the valve, and can save a lot of materials and reduce the cost.

3. Fluid resistance

Larger, the fluid resistance coefficient is 2.8~6.4

Still smaller than the fluid resistance coefficient of the flange lift check valve (6~12)

4. Installation method

It can be installed horizontally or vertically, with light weight and easy installation.

5. Cracking pressure

Very small, the disc can fully open the valve under a small pressure difference.

6. Reliability

The valve is a whole structure, simple and compact, the impact force is small when the valve is closed, the water hammer pressure is very small, the valve life is long, and the reliability is high.

Field of Application:

Size Range: 1/2"~8" DN15-DN200

Working Pressure: PN10~PN100

Working Temperature: -196~540°C

Application for: By selecting different materials, it can be applied to a variety of media such as water, steam, oil, nitric acid, acetic acid, strong oxidizing media, and urea.

Technical Specification:

Design standard: JB/T8937

Face to Face dimension: JB/T8937

Connection flange: JB/T74-90, GB/T13402, GB/T9112-9124, HG/T20592~20635

Pressure temperature rating: JB/T74, GB/T9124, HG20604~20625

Test standard: JB/T9092

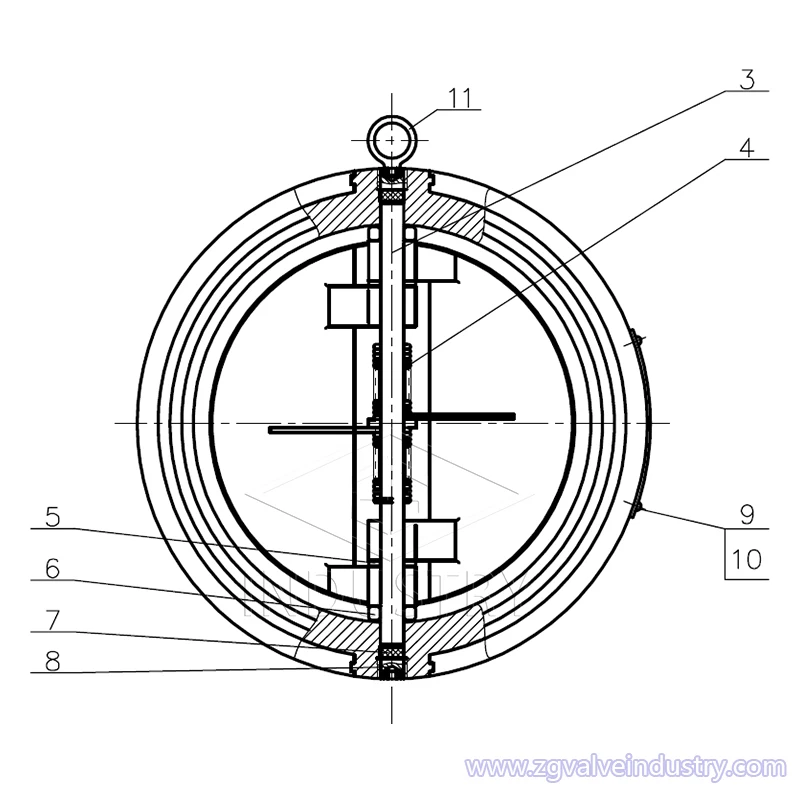

Part Name | Material |

Body | Cast Iron/Ductile Iron |

Plate | Dl/Stainless Steel/Bronze |

Spring | Stainless Steel |

Hinge Pin | Stainless Steel |

Stop Pin | Stainless Steel |

Plug | Carbon Steel |

Body Bearing | PTFE |

Spring Bearing | PTFE |

Eye Bolt | Carbon Steel |

Body Seat | EPDM/CR/FKM/NR |

DN | Inch | BS Table D/E | ASME CL150 | PN10 & PN16 |

ΦA | ΦA | ΦA | ||

50 | 2" | 107 | 101 | 107 |

65 | 2 1/2" | 127 | 120 | 127 |

80 | 3" | 142 | 133 | 142 |

100 | 4" | 161 | 171 | 162 |

125 | 5" | 192 | 192 | 192 |

150 | 6" | 213 | 219 | 218 |

200 | 8" | 270 | 276 | 273 |

250 | 10" | 334 | 337 | 328 |

300 | 12" | 380 | 407 | 378/382 |

350 | 14" | 442 | 447 | 438/442 |

400 | 16" | 492 | 510 | 487/494 |

450 | 18" | 554 | 546 | 537/554 |

500 | 20" | 615 | 603 | 592/616 |

600 | 24" | 725/723 | 714 | 694/733 |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices