New design poultry feed pellet making machine home use fish feed extruder machine pellet

- Category: >>>

- Supplier: Zhengzhou Runxiang Machinery Equipment Co. Ltd.Zhengzhou Ltd.

Share on (1601305538676):

Product Overview

Description

Application

The Floating Feed Pelleting Machine can make many kinds of fodder for different kinds of animal fodder. It can make poultry-fodder, pet-fodder, as well as aquaculture-fodder and fishery feed, which is also called floating feed.

It is apply to the pretreatment of the animal fodder, so as to reduce loss of nutrition, advance the protein content So the fodder will be digested easier by animals.

The poultry-fodder can feed chicken, rabbit, sheep, pig, horse cattles and so on The pet-fodder can feed dogs, cats, goldfish etc .

It is apply to the pretreatment of the animal fodder, so as to reduce loss of nutrition, advance the protein content So the fodder will be digested easier by animals.

The poultry-fodder can feed chicken, rabbit, sheep, pig, horse cattles and so on The pet-fodder can feed dogs, cats, goldfish etc .

The Fishery-feed can feed the fish, shrimps, crab, eel, catfish, batrachia and so on.

Product Description

We could change the configuration of floating fish feed pellet machine according to the output you want. You could get many flavors, new shapes, good tastes, nutritional pet food by adjusting raw materials, water, temperature of the processing line. So,it's widely used in the process of dog food, cat food, fish food and many other pets food.

This mini fish feed pellet machine can be used to produce dog food, cat food, meanwhile it can produce fish pellets; the pellets size can be from 1.5mm to 15mm by adjusting the moulds from extruder .This dry type fish feed machine is an ideal for small and medium fish farm holders or feed processing plant.

This mini fish feed pellet machine can be used to produce dog food, cat food, meanwhile it can produce fish pellets; the pellets size can be from 1.5mm to 15mm by adjusting the moulds from extruder .This dry type fish feed machine is an ideal for small and medium fish farm holders or feed processing plant.

Feature:

1. This fish feed extruder is widely used for producing floating feed pellets of all kinds of aquatic animal.

2. Advanced technology and humanized design ensures easy operation and reliable performance.

3. High efficiency, low power consumption

4. Screw sleeve of this small fish food extruder adopts enchase alloy steel strip structure, which guarantees long service life.

5. Different moulds can be chosen to make pellets with different diameters and shapes.

6. Feed pellets dia. Is 0.9-15mm.

2. Advanced technology and humanized design ensures easy operation and reliable performance.

3. High efficiency, low power consumption

4. Screw sleeve of this small fish food extruder adopts enchase alloy steel strip structure, which guarantees long service life.

5. Different moulds can be chosen to make pellets with different diameters and shapes.

6. Feed pellets dia. Is 0.9-15mm.

To make fish feed, you will need a variety of raw materials, including:

1. Fishmeal: This is the main protein source in fish feed and is made from ground-up fish.2. Soybean meal: This is another protein source and is made from ground-up soybeans.

3. Wheat bran: This is a carbohydrate source and is made from the outer layer of wheat.

4. Corn: This is another carbohydrate source and is made from ground-up corn.

5. Fish oil: This is a source of fat and helps to make the pellets more palatable.

6. Vitamins and minerals: These are essential nutrients that help to promote the healthy growth and development of fish.

Size Information

Model | WSJY40-C | WSJY50-C | WSJY60-C | WSJY70-B | WSJY80-B |

Capacity --- kg/h | 30-40 | 60-80 | 120-150 | 180-200 | 200-300 |

Pelleting Diameter--- mm | 1-8 | 1—8 | 1 —10 | 1-10 | 1 —10 |

Motor Power--- kw | 5.5 | 11 | 15 | 18.5 | 22 |

Cutting Power--- w | 400 | 400 | 400 | 400 | 1100 |

Screw Rod Diameter-- mm | 40 | 50 | 60 | 70 | 80 |

Cooking degree | >95% | >95% | >95% | >95% | >95% |

Size(m) | 1.4*1.03*1.1 | 1.45*1.08*1.25 | 1.46*1.14*1.25 | 1.6*1.4*1.35 | 1.6*1.4*1.35 |

Weight(kg) | 260 | 350 | 355 | 580 | 700 |

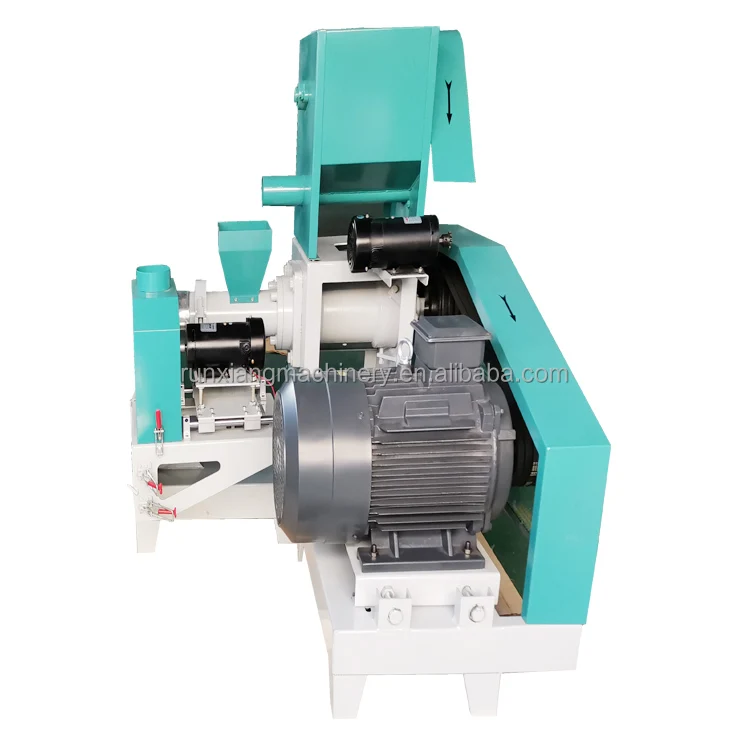

Detailed Images

1.Adopt a soft knife fit,Achieve stepless variable speed,Can cut discharge materials into required length products,And not prone to burrs.

2.Novel design,Unique,Simple structure,Easy to assemble, easy to disassemble and disassemble,Easy to operate.

3.The screw sleeve and screw are made of abrasion resistant high-temperature alloy steel material,Heat treatment forming,Has the advantages of abrasion resistant and long life.

4.Built with a unique supercharged punch device,Ensure feed output and quality;And equipped with electric heating device to increase feed puffing rate.

5.The main motor adopts high qualityYSeries three-phase motor,Ensure strong power.

6.Speed adjustment feeding device,More convenient to operate,Even feeding,Prevent holding the machine.

7.The discharge template is easy to replace,If you need feed with different hole diameters, just replace the required hole diameter template.

8.The floating capsules puffed feed produced can float on the water,Fish and poultry and livestock are prone to digestion,Convenient observation of frog fish by hand The amount of food,No waste of feed.

9. Can produce immersive aquatic products,Poultry and livestock particle feed.

10.The screw adopts split structure,Cleaning,Easy to replace.

2.Novel design,Unique,Simple structure,Easy to assemble, easy to disassemble and disassemble,Easy to operate.

3.The screw sleeve and screw are made of abrasion resistant high-temperature alloy steel material,Heat treatment forming,Has the advantages of abrasion resistant and long life.

4.Built with a unique supercharged punch device,Ensure feed output and quality;And equipped with electric heating device to increase feed puffing rate.

5.The main motor adopts high qualityYSeries three-phase motor,Ensure strong power.

6.Speed adjustment feeding device,More convenient to operate,Even feeding,Prevent holding the machine.

7.The discharge template is easy to replace,If you need feed with different hole diameters, just replace the required hole diameter template.

8.The floating capsules puffed feed produced can float on the water,Fish and poultry and livestock are prone to digestion,Convenient observation of frog fish by hand The amount of food,No waste of feed.

9. Can produce immersive aquatic products,Poultry and livestock particle feed.

10.The screw adopts split structure,Cleaning,Easy to replace.

Advantage of floating fish feed pellet machine:

1) High extruding temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

2) There are many models with different capacity to meet customers' demands.

3) Main parts, like sleeve and screw, of this pellet extruder machine, are made of alloy material, wearable, durable.、

1) High extruding temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

2) There are many models with different capacity to meet customers' demands.

3) Main parts, like sleeve and screw, of this pellet extruder machine, are made of alloy material, wearable, durable.、

4) Advanced design, and stable performance.

5) The cutting device can be adjusted to make pellets of different length.

6) The floating pellets can float on the water for about 24 hours,which can be seen clearly and it won't waste feed. The feed is very catering and easy to be digested for animals, especially fish.

5) The cutting device can be adjusted to make pellets of different length.

6) The floating pellets can float on the water for about 24 hours,which can be seen clearly and it won't waste feed. The feed is very catering and easy to be digested for animals, especially fish.

Working principle

The Fish Feed Making Machine works by grinding and mixing raw materials such as fishmeal, soybean meal, wheat bran, corn, and other ingredients to create a homogeneous mixture. The mixture is then passed through the extrusion chamber where it is compressed and formed into pellets of a specific shape and size.

The extrusion process involves the use of high temperatures and pressure to transform the raw materials into pellets. The high temperatures help to kill any bacteria or pathogens that may be present in the raw materials, while the pressure helps to form the pellets into the desired shape and size.

The extrusion process involves the use of high temperatures and pressure to transform the raw materials into pellets. The high temperatures help to kill any bacteria or pathogens that may be present in the raw materials, while the pressure helps to form the pellets into the desired shape and size.

Others

Diesel working on feed pellet machine.

1. The main power can use diesel engine, the granulation work can be done anywhere.

2. It solves the problem that the electricity is inconvenient, and the three-phase power can not be used, but the output is required.

3. Pellet size 1-8mm can be chosen.

4. It is used in the production of floating fish feed, suitable for small, medium family production, and large professional feed processing plant.

5. The produced feed is suitable for cat, dog, pig, bird, fish, shrimp, and other aquatic animals.

6. High temperature and high pressure can kill common pathogenic microbes and parasites.

2. It solves the problem that the electricity is inconvenient, and the three-phase power can not be used, but the output is required.

3. Pellet size 1-8mm can be chosen.

4. It is used in the production of floating fish feed, suitable for small, medium family production, and large professional feed processing plant.

5. The produced feed is suitable for cat, dog, pig, bird, fish, shrimp, and other aquatic animals.

6. High temperature and high pressure can kill common pathogenic microbes and parasites.

Packing and details

Recommending Styles

We Recommend

New Arrivals

New products from manufacturers at wholesale prices