100KW to 500KW on Off GridHorizontal Axis Wind Turbine Generator 360V with 220V Output Voltage for Wind Power Applications

- Category: >>>

- Supplier: Beijing Aokun Energy Co. Ltd.Beijing Ltd.

Share on (1601305668101):

Product Overview

Description

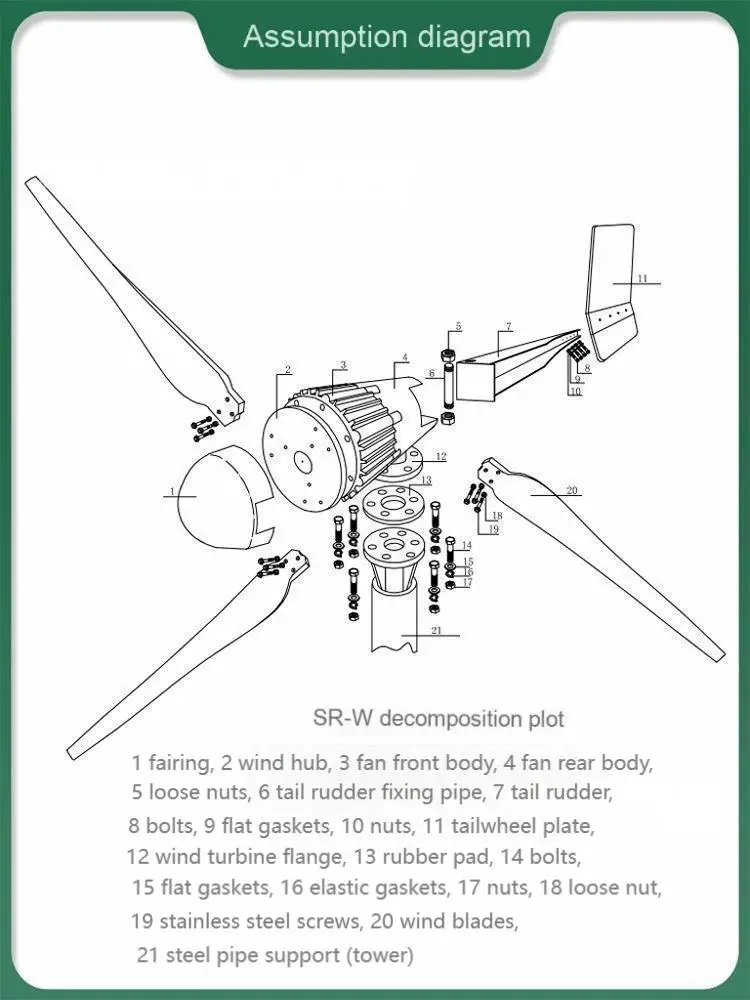

Product Description

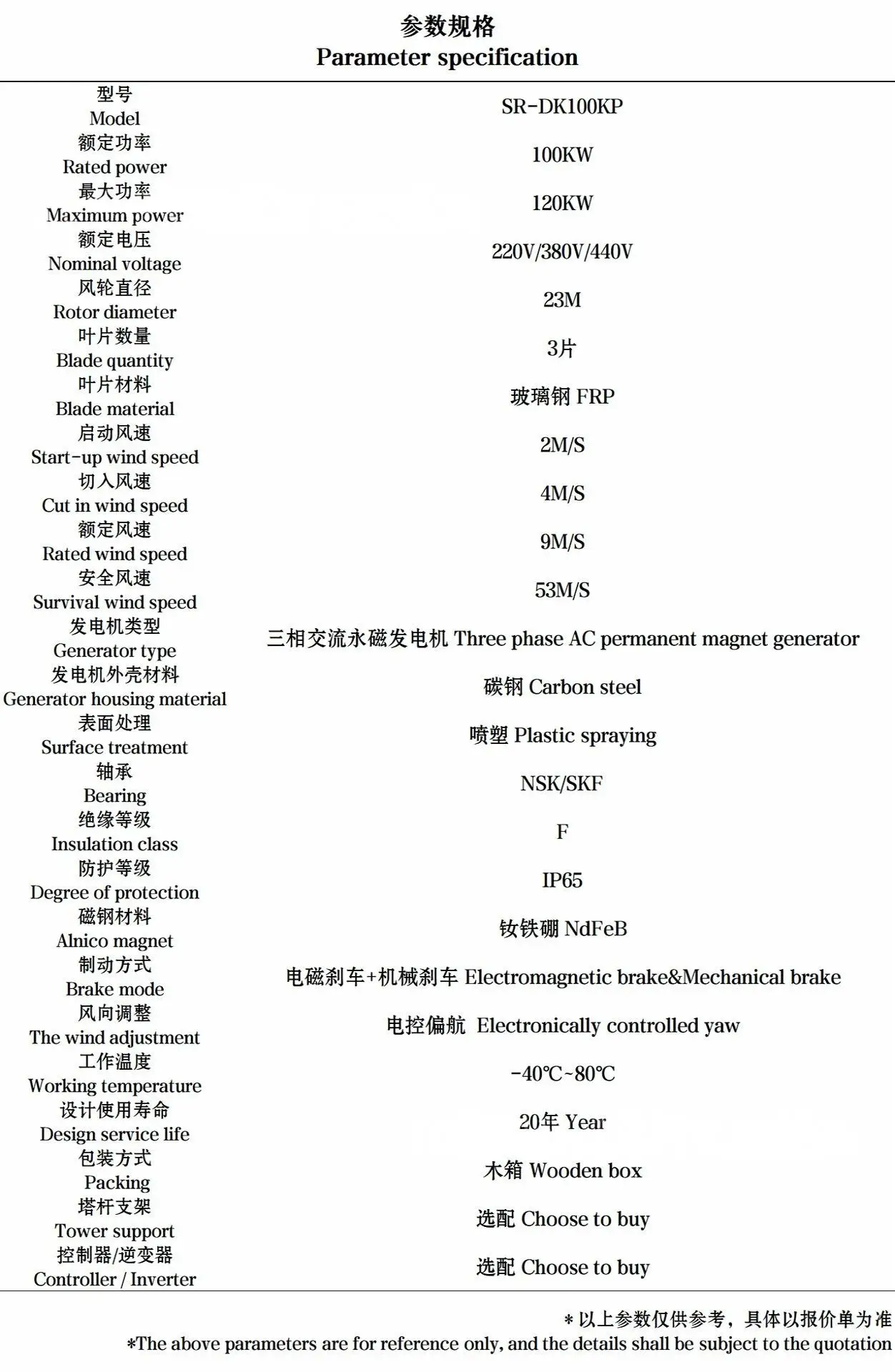

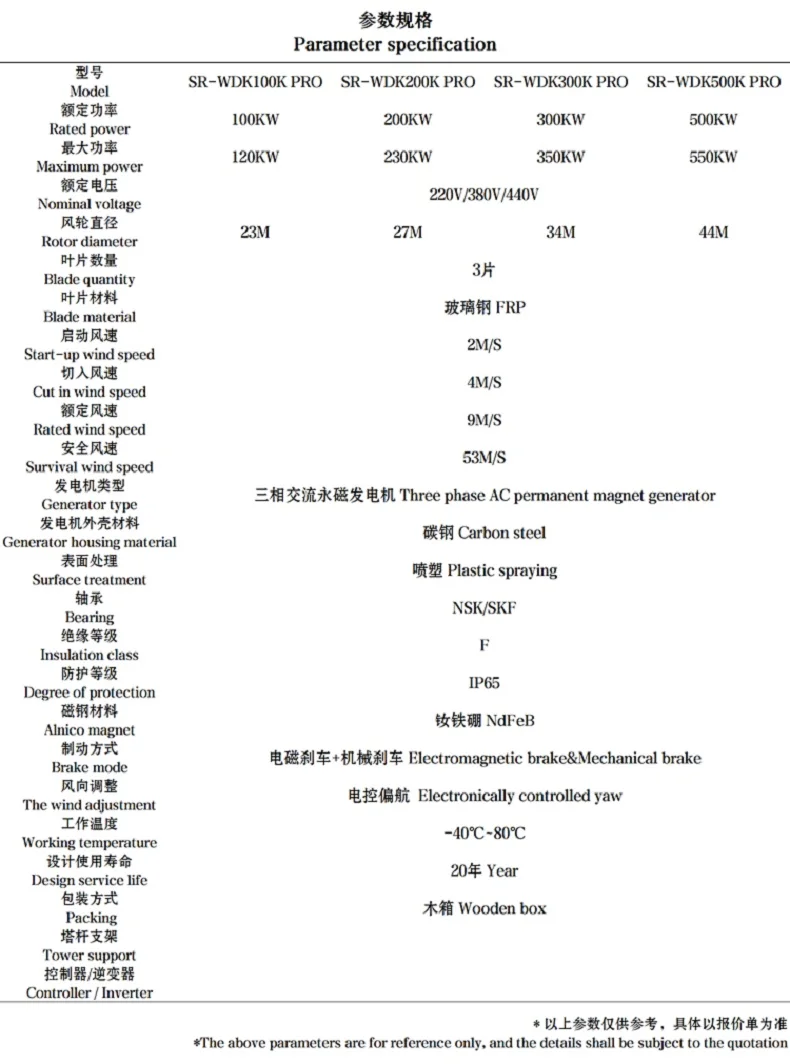

Specification

Item | Value |

Product name | Horizontal axis wind power system |

Brand Name | Aokun |

Model Number | AK100-PP |

Output Voltage | AC220V/380V/440 |

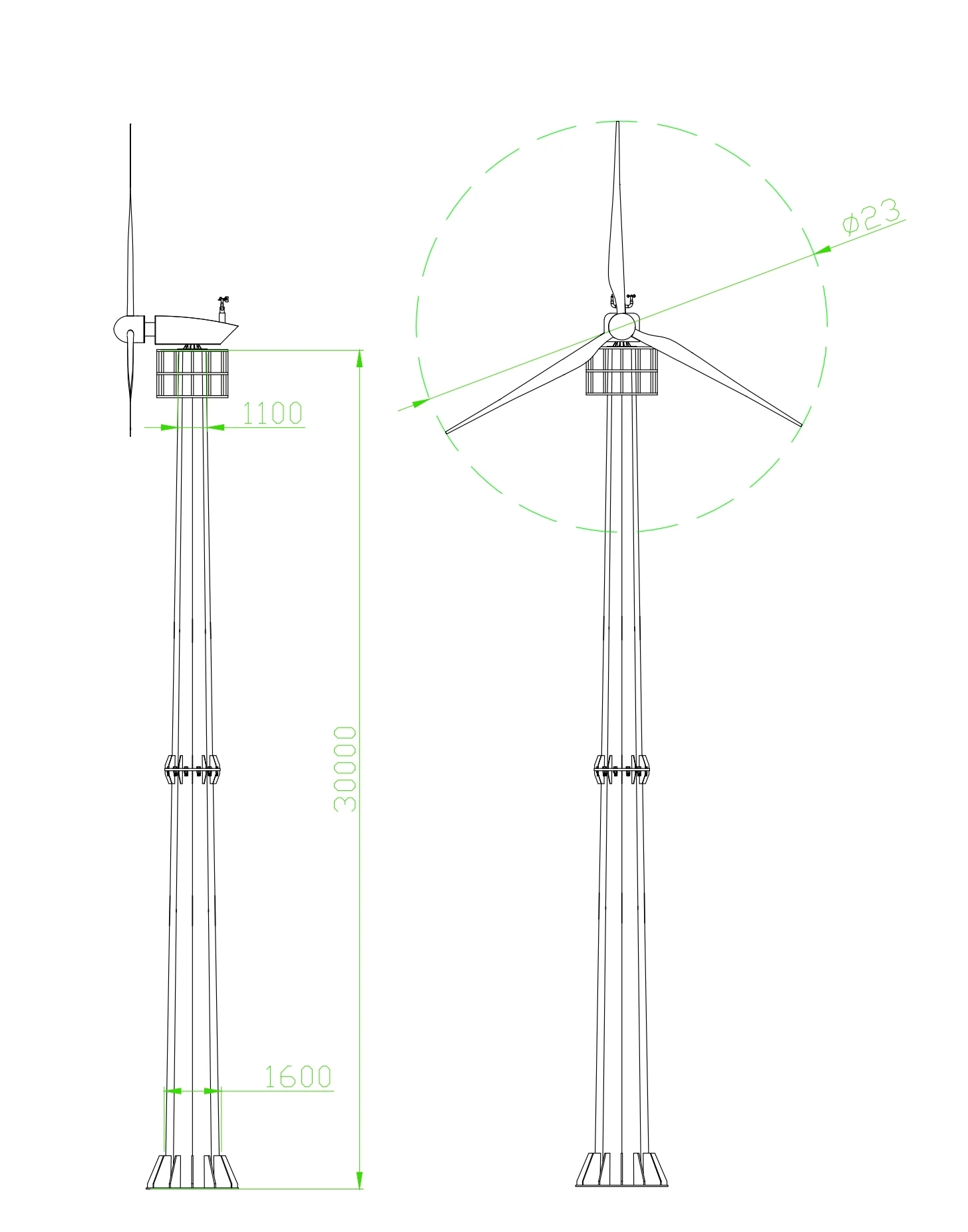

Rotor diameter | 23m |

Capacity | 100KW |

Start wind speed | 2.0m/s |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

FAQ

1. How does a horizontal-axis wind power system capture wind energy?

The horizontal-axis wind power system captures wind energy mainly through its unique design, which includes blades and a generator. The blades are the key components of the wind turbine, designed to capture wind energy as efficiently as possible. When wind passes over the blades, the shape and angle of the blades create lift and drag forces that drive the blades to rotate. The rotation of the blades is transmitted to the generator via the main shaft. Inside the generator, the rotor spins in a magnetic field, generating electricity. The electricity is then transmitted to the power grid through wires, thus converting wind energy into electrical energy. To improve efficiency, modern wind turbine blades are often made of advanced materials and designed with aerodynamic features to adapt to varying wind speeds and directions.

2. When choosing a wind turbine, which key parameters need to be considered?

When selecting a wind turbine, there are several key parameters that must be taken into account. First is the rated power, which determines the maximum amount of electricity that the wind turbine can produce under ideal conditions. Next is the cut-in wind speed, which is the minimum wind speed required for the wind turbine to start rotating and generating electricity. Additionally, the cut-out wind speed is important, referring to the highest wind speed at which the wind turbine stops operating to avoid damage. The length and number of blades of the wind turbine also affect its efficiency in capturing wind energy. Longer blades mean a larger area for capturing wind energy, but they also increase costs and the strength requirements for materials. Finally, the durability and maintenance costs of the wind turbine are also important considerations, as they directly relate to long-term economic benefits and operational stability.

3. How is the noise level of wind turbines assessed and its impact on the surrounding environment?

Assessing the noise level of wind turbines typically involves measuring their sound pressure levels under different operating conditions. The evaluation of noise levels needs to be conducted in the surrounding environment of the wind turbines, including sensitive areas such as residential areas, commercial zones, and protected areas. Noise assessment should consider the sound produced by wind turbines during start-up, operation, and shutdown processes, as well as the changes in noise at different wind speeds. In addition, the range and extent of noise propagation should be evaluated to ensure compliance with local environmental regulations and standards. To reduce the impact of noise on the surrounding environment, various measures can be taken, such as optimizing blade design, using soundproofing materials, and adjusting the layout and location of wind turbines. By employing these methods, noise levels can be reduced without compromising the efficiency of wind power generation, thus protecting the surrounding environment.

4. How are wind turbine blades designed to adapt to different wind speeds and climate conditions?

The design of wind turbine blades is customized according to the expected operating environment and required performance parameters of the wind turbine. Blades are typically made from lightweight yet strong materials such as fiberglass or carbon fiber reinforced plastics to ensure good performance under various wind speeds and climate conditions. The length, shape, and angle of the blades are carefully designed to maximize the capture of wind energy and convert it into electrical energy. During the design process, engineers use computational fluid dynamics (CFD) to simulate the effects of different wind speeds and directions on the blades, ensuring efficient operation under various conditions. Additionally, the tips of the blades are often designed to be adjustable to reduce wind resistance in strong wind conditions and prevent damage to the blades. The surface coatings of the blades are also chosen for their resistance to ultraviolet rays and corrosion to withstand long-term outdoor exposure. To adapt to extreme climate conditions, such as freezing or sandstorms, blade designs include special protective measures. For example, heating elements can prevent the accumulation of ice, and the selection of coatings and materials can reduce the impact of sand on blade performance. With these design considerations, wind turbines can operate stably under various climate conditions while reducing maintenance needs and extending their service life.

5. How does the wind turbine system ensure safe operation during extreme weather conditions?

Firstly, the wind turbine system is equipped with advanced monitoring equipment that continuously tracks key parameters such as wind speed, wind direction, temperature, and vibration. This data is transmitted to the central control system, which automatically initiates protective procedures if conditions exceed safe thresholds. For instance, when wind speeds are too high, the blade adjustment system quickly alters the angle to reduce wind resistance, or even stops rotation entirely to prevent damage. Additionally, the generator's braking system can be activated when necessary to ensure that the blades do not become uncontrollable due to excessive wind force.

During extreme weather events such as freezing conditions or sandstorms, the wind turbine system takes additional protective measures. Heating elements are activated to prevent the accumulation of ice, while special coatings and materials reduce wear and tear from sand on the blades and generator. After extreme weather events, the system performs self-checks to ensure all components are functioning properly, and maintenance and repairs are carried out when necessary to ensure that the wind turbines can quickly return to optimal operating condition. Through these measures, the wind turbine system can maintain safe and stable operation during extreme weather conditions, ensuring the continuity and reliability of power supply.

The horizontal-axis wind power system captures wind energy mainly through its unique design, which includes blades and a generator. The blades are the key components of the wind turbine, designed to capture wind energy as efficiently as possible. When wind passes over the blades, the shape and angle of the blades create lift and drag forces that drive the blades to rotate. The rotation of the blades is transmitted to the generator via the main shaft. Inside the generator, the rotor spins in a magnetic field, generating electricity. The electricity is then transmitted to the power grid through wires, thus converting wind energy into electrical energy. To improve efficiency, modern wind turbine blades are often made of advanced materials and designed with aerodynamic features to adapt to varying wind speeds and directions.

2. When choosing a wind turbine, which key parameters need to be considered?

When selecting a wind turbine, there are several key parameters that must be taken into account. First is the rated power, which determines the maximum amount of electricity that the wind turbine can produce under ideal conditions. Next is the cut-in wind speed, which is the minimum wind speed required for the wind turbine to start rotating and generating electricity. Additionally, the cut-out wind speed is important, referring to the highest wind speed at which the wind turbine stops operating to avoid damage. The length and number of blades of the wind turbine also affect its efficiency in capturing wind energy. Longer blades mean a larger area for capturing wind energy, but they also increase costs and the strength requirements for materials. Finally, the durability and maintenance costs of the wind turbine are also important considerations, as they directly relate to long-term economic benefits and operational stability.

3. How is the noise level of wind turbines assessed and its impact on the surrounding environment?

Assessing the noise level of wind turbines typically involves measuring their sound pressure levels under different operating conditions. The evaluation of noise levels needs to be conducted in the surrounding environment of the wind turbines, including sensitive areas such as residential areas, commercial zones, and protected areas. Noise assessment should consider the sound produced by wind turbines during start-up, operation, and shutdown processes, as well as the changes in noise at different wind speeds. In addition, the range and extent of noise propagation should be evaluated to ensure compliance with local environmental regulations and standards. To reduce the impact of noise on the surrounding environment, various measures can be taken, such as optimizing blade design, using soundproofing materials, and adjusting the layout and location of wind turbines. By employing these methods, noise levels can be reduced without compromising the efficiency of wind power generation, thus protecting the surrounding environment.

4. How are wind turbine blades designed to adapt to different wind speeds and climate conditions?

The design of wind turbine blades is customized according to the expected operating environment and required performance parameters of the wind turbine. Blades are typically made from lightweight yet strong materials such as fiberglass or carbon fiber reinforced plastics to ensure good performance under various wind speeds and climate conditions. The length, shape, and angle of the blades are carefully designed to maximize the capture of wind energy and convert it into electrical energy. During the design process, engineers use computational fluid dynamics (CFD) to simulate the effects of different wind speeds and directions on the blades, ensuring efficient operation under various conditions. Additionally, the tips of the blades are often designed to be adjustable to reduce wind resistance in strong wind conditions and prevent damage to the blades. The surface coatings of the blades are also chosen for their resistance to ultraviolet rays and corrosion to withstand long-term outdoor exposure. To adapt to extreme climate conditions, such as freezing or sandstorms, blade designs include special protective measures. For example, heating elements can prevent the accumulation of ice, and the selection of coatings and materials can reduce the impact of sand on blade performance. With these design considerations, wind turbines can operate stably under various climate conditions while reducing maintenance needs and extending their service life.

5. How does the wind turbine system ensure safe operation during extreme weather conditions?

Firstly, the wind turbine system is equipped with advanced monitoring equipment that continuously tracks key parameters such as wind speed, wind direction, temperature, and vibration. This data is transmitted to the central control system, which automatically initiates protective procedures if conditions exceed safe thresholds. For instance, when wind speeds are too high, the blade adjustment system quickly alters the angle to reduce wind resistance, or even stops rotation entirely to prevent damage. Additionally, the generator's braking system can be activated when necessary to ensure that the blades do not become uncontrollable due to excessive wind force.

During extreme weather events such as freezing conditions or sandstorms, the wind turbine system takes additional protective measures. Heating elements are activated to prevent the accumulation of ice, while special coatings and materials reduce wear and tear from sand on the blades and generator. After extreme weather events, the system performs self-checks to ensure all components are functioning properly, and maintenance and repairs are carried out when necessary to ensure that the wind turbines can quickly return to optimal operating condition. Through these measures, the wind turbine system can maintain safe and stable operation during extreme weather conditions, ensuring the continuity and reliability of power supply.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices