Vility Cheap Automatic Roll to Roll Label Sticker Plastic Die Cutting Plate Embossing Machine

- Category: >>>

- Supplier: Shenzhen Vility Automatic Machinery Co. Ltd.Shenzhen Ltd.

Share on (1601307670487):

Product Overview

Description

Products Description

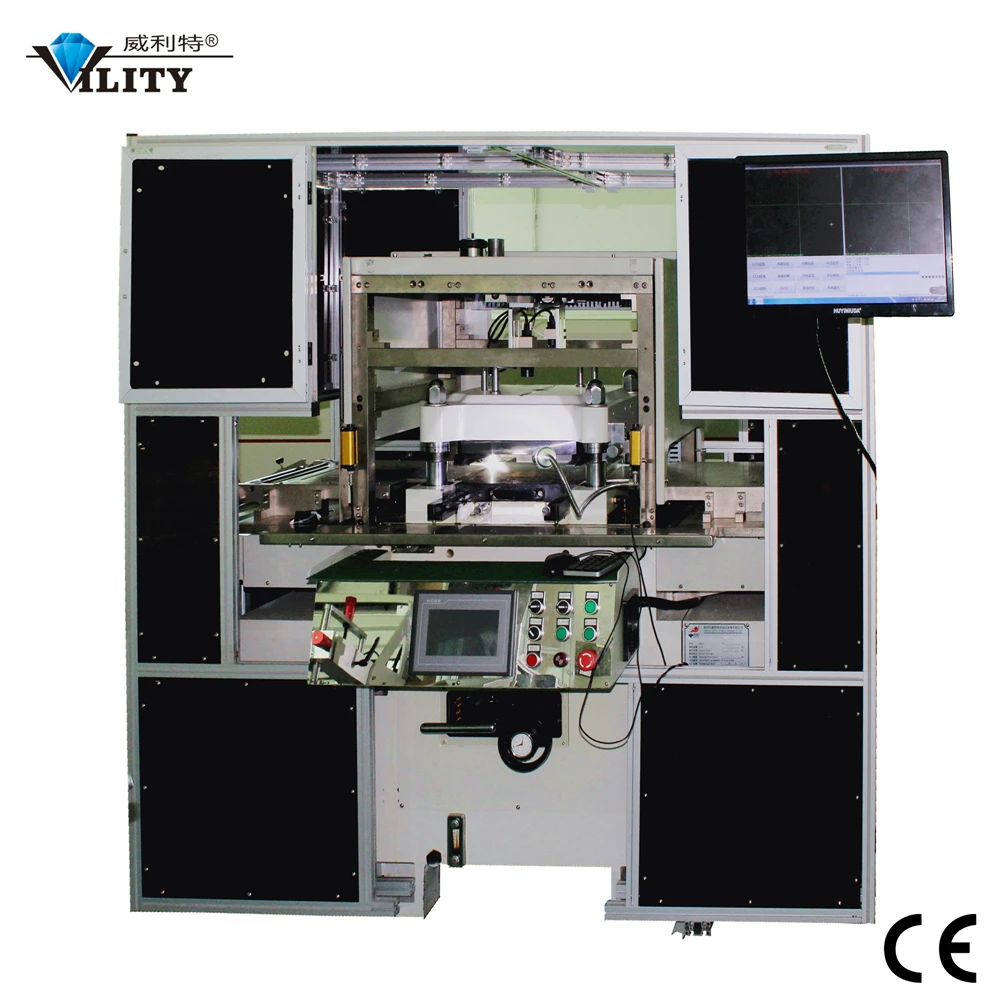

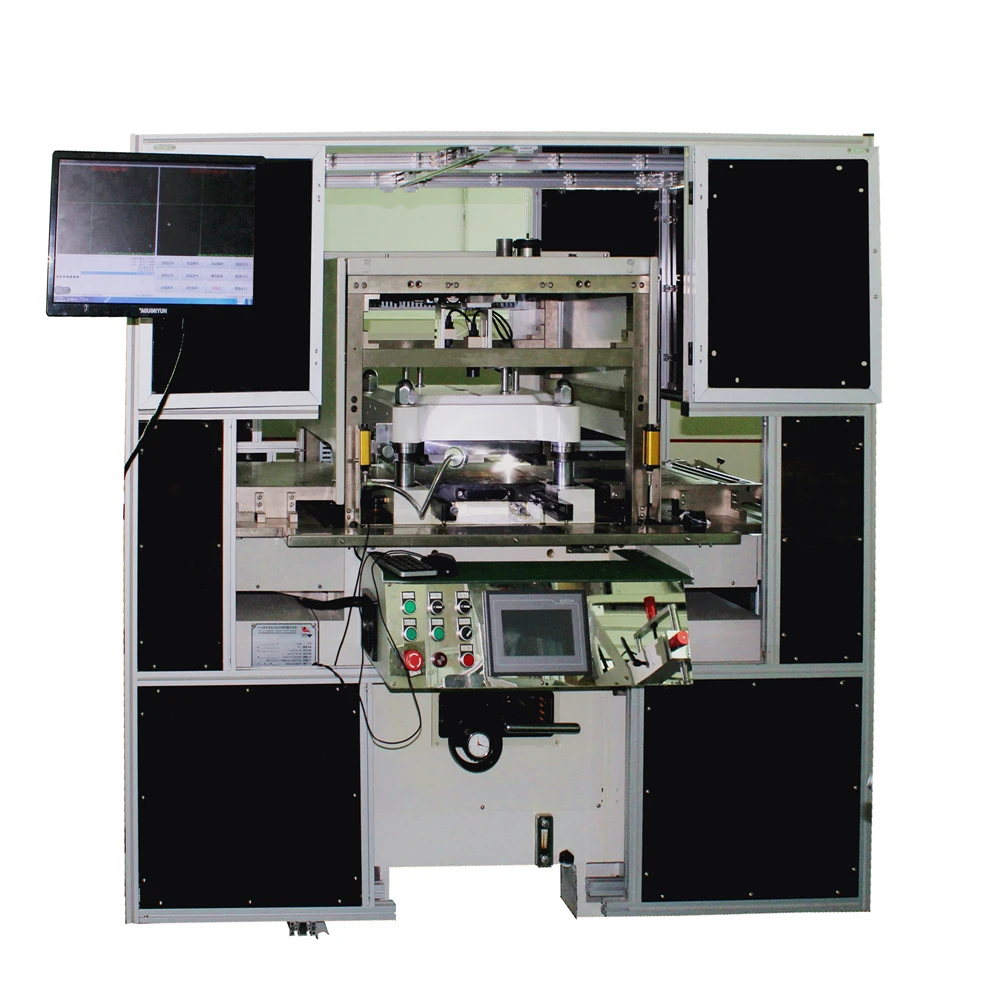

Automatic Roll To Roll CCD Alignment Die-cutting Machine

CCD roll-to-roll die-cutting machine is a kind of high-precision and high-efficiency automatic die-cutting equipment. Among them, the equipment mainly contains: CCD moving platform, high precision XYθ alignment platform, pulling mechanism, guiding mechanism, releasing mechanism, punching and cutting mechanism. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, etc. The finished die-cutting products and scrap are separated according to the specified track. Once the equipment is adjusted, the machine will be automatically completed without any operation by personnel. The picture below is the machine design and the actual picture of the die cutting machine.

Electronic Samples Roll to Roll CCD regulation stamping and die cutting machine,Advanced & durable hydraulic circuit and steady

electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance.

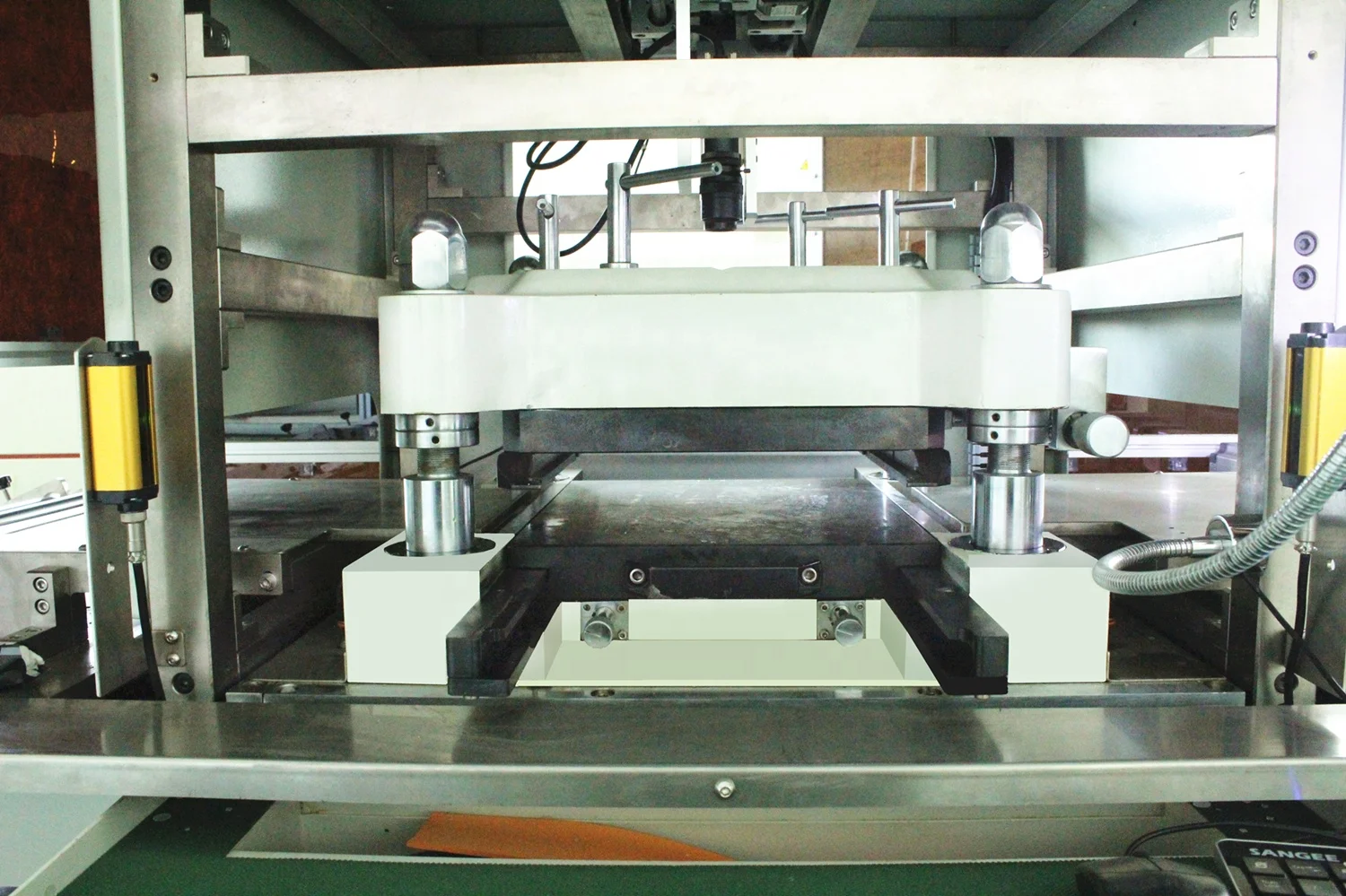

4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders.

Electronic Samples Roll to Roll CCD regulation stamping and die cutting machine,Advanced & durable hydraulic circuit and steady

electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance.

4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders.

Details Images

Product Paramenters

Customized or not | Yes |

Warranty | 1 year |

The product display diagram is as follows:

The characteristics

1. XYθ alignment platform and CCD are fixed on the die-cutting machine to make the alignment smooth. 2. The material is fixed on the loading suction platform, easy to operate.

3. Punching and cutting accuracy is completely controlled by CCD, accurate positioning.

4. Human-machine interface control + button switch, can set a variety of functions and parameters, easy to operate.

5. Safety pressure plate, photoelectric switch, emergency stop button, thorough safety protection.

6. CCD automatic positioning punching and cutting, can automatically adjust the field of view of CCD according to the size of the material.

7. CCD automatically calculates the spatial position of the material and the mold according to the Mark point on the material, and instructs the motor motion control to adjust the platform X, Y, θ, and automatic punching and cutting.

8. The equipment will automatically finish punching and cutting when it is adjusted, the number of punching and cutting can be set automatically, and an alarm device is installed for easy management.

9. Can be customized according to customer requirements to meet different use requirements.

3. Punching and cutting accuracy is completely controlled by CCD, accurate positioning.

4. Human-machine interface control + button switch, can set a variety of functions and parameters, easy to operate.

5. Safety pressure plate, photoelectric switch, emergency stop button, thorough safety protection.

6. CCD automatic positioning punching and cutting, can automatically adjust the field of view of CCD according to the size of the material.

7. CCD automatically calculates the spatial position of the material and the mold according to the Mark point on the material, and instructs the motor motion control to adjust the platform X, Y, θ, and automatic punching and cutting.

8. The equipment will automatically finish punching and cutting when it is adjusted, the number of punching and cutting can be set automatically, and an alarm device is installed for easy management.

9. Can be customized according to customer requirements to meet different use requirements.

Accessories

The Feeder and Receiver features:

(1) photoelectric control feeding, avoid the surface damage of the material.

(2) feeding speed, time, can adjust at will.

(3) the feeding starting speed, can adjust at will, start frequency starting from 0 up to run slowly, avoid the start too fast,

cause the material surface scratches.

(4) equipped with an automatic protective device.

(2) feeding speed, time, can adjust at will.

(3) the feeding starting speed, can adjust at will, start frequency starting from 0 up to run slowly, avoid the start too fast,

cause the material surface scratches.

(4) equipped with an automatic protective device.

Main machine feature---CCD die cutting machine

This equipment mainly includes die-cutting unit, equipped with CCD moving platform on both sides of the die-cutting unit, high precision XYθ alignment platform, stable alignment, human-machine interface control + button switch, can set a variety of functional parameters, easy to operate; CCD automatic positioning punching, can automatically adjust the field of view of CCD according to the size of the material.

CCD automatically calculates the spatial position of material and mold according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation for automatic punching and cutting.

CCD automatically calculates the spatial position of material and mold according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation for automatic punching and cutting.

New Technology (CCD automatic XYθ rotary alignment cutting)

1.CCD automatic XYθ rotation alignment adjustment .New Technology (CCD automatic XYθ rotary alignment cutting)

2.Quick screen changer, high production efficiency .

3.CCD high precision alignment ±0.02mm .

4.No pause at halfway, electric eye cursor .

5.No requirements for the accuracy of pulling materials .

6.Provincialworkers, one person can take care of 3 machines.

2.Quick screen changer, high production efficiency .

3.CCD high precision alignment ±0.02mm .

4.No pause at halfway, electric eye cursor .

5.No requirements for the accuracy of pulling materials .

6.Provincialworkers, one person can take care of 3 machines.

Product packaging

We Recommend

New Arrivals

New products from manufacturers at wholesale prices