ABS PE PP PC plastic socket panel Wall switch panel High Precision PC Injection plastic Customized Mold Plastic Parts

- Category: >>>

- Supplier: Xiamen Jingwei Industry & Trade Co. Ltd.Xiamen Ltd.

Share on (1601315020175):

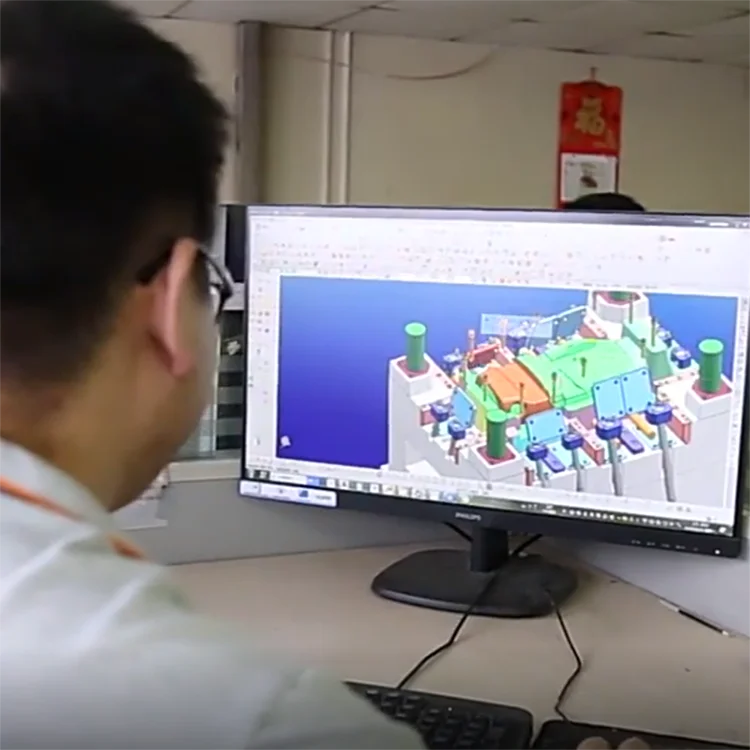

Product Overview

Description

Products Description

Mold Material | P20/718/738/NAK80/SS316 |

Plastic Material | PC/ABS, ABS, PC, PVC, PA66, POM or other you want |

silicon rubber Material | NR, NBR, SBR, EPDM, IIR, CR, SILICONE, VITON,etc |

Plastic Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

Drawing format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, etc.. |

The Way of Color Contrast for Plastic | RAL PANTONE |

Service Project | To provide production design, production and technical service, mould development and processing, product assembly and packaging,etc |

Company Profile

Product packaging

Customer Photos

FAQ

1.Does your company make mould by yourself? Yes, we are injection mold manufacturer over 17 yearsexperience. 2.What material should I use for my project? Most material is selected with the requirement frombuyer. lf you don't have a idea on material option, wecan recommend you the proper material to quote asper the function or usage of the parts. 3.What is the typical process of a new project? We will evaluate your part design and modify it to be efficiently injection molded manufacture procedureThen, we will issue the DFM report for our clients tocheck and approval. Next, the mold will be put into aninjection molding press to make out production partsOn average the entire process. would takes around4-7 weeks 4.What's the software you will use to check the drawing?And what's format of drawing workable for you ? Our designers and engineers all use AUTO CAD andSoliworks software to check 2D and 3D drawings.We can check the drawings with Al, DWG (CAD)and STP (3D) or IGS (3D) formats. 5.Will you send me the free sample? Yes, We will send free sample to you. 6.How to pack the molds and products? For mold. we will be coated one-laver anti-rust oil firstand then also will be covered thin films on the mouldfinally pack into non-fumigation wooden case.And asto products, would be packed as per export standardPoly Bag Master Carton or as per customer's spe-cial requirement to pack.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices