Leading technology Alloy Steel SCr420 SCr420H SCR420HRCh Die Forging Hot Forging Ring

- Category: >>>

- Supplier: Shandong Meide Import And Export Co. Ltd.Shandong Ltd.

Share on (1601318065628):

Product Overview

Description

Product specification

Name | Forging ring |

Material | Steel ,Stainless Steel,Carbon steel,Brass,Aluminum or as your requirements |

Size | M1-M36,or non-standard as request&design,Customized Size |

Thread Type | Fine Thread Or Coarse Thread or Hi-Lo Thread |

Finish | Plain, black, zinc plated/according to your requirement |

Standard | ISO,GB,DIN,JIS,ANSI/ASME,BSW,Non-standard. or base on the Drawings or Samples |

Tolerance | 0.01-0.05mm can also be customized |

Design 3D Mould Drawing | • Our Engineer will design 3D mould drawing for your confirmation. • Design Software: Pro-E, Iges, UG, CAD etc • Mould Base Material: LKM, HASKCO, LOCAL, DME etc • Mould Core Material: 718H, S136H, NAK80, P20 ect • Mould Cavity: Single & Multi Cavity •Runner: Cold or Hot Runner • Gate: Pinpoint Gate or Edge Gate • Finish: Polish or Semi-matt |

1.Flat flange 2.Blind flange 3.Slip on 4.Lap joint flange 5.Welding neck Flange 6.Socket welding 7.Threaded flange 8.Long welding neck flange. etc. | |

Connection | Raised Face, Flat Face, Ring Type Joint, Lap-Joint Face, Large Male-Female, Small Male-Female, Large Tongue, Groove, Small-Tongue, Groove, etc |

Package | 1.>Standard export packaging (Plywood Case Of Outside,Plastic Cloth Of Inside). 2:As Customers' Requirements |

Certificate | TUV,ISO9001:2015; |

Applications | Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry,and general pipes connecting projects etc. |

Definition And Principle

Forging is a processing method that uses pressure to cause plastic deformation of metal materials, thereby obtaining blanks or parts with a certain shape, size, and performance. For forged rings, it is to process metal blanks into annular structures. During

the forging process, by applying external force to the blank, such as hammering or pressing by a press machine, the grain structure inside the metal is refined and optimized, improving the mechanical properties of the metal.

the forging process, by applying external force to the blank, such as hammering or pressing by a press machine, the grain structure inside the metal is refined and optimized, improving the mechanical properties of the metal.

Free Forging

In the process of free forging, the metal billet is deformed by impact force or pressure between the upper and lower anvils. For forged rings, free forging can produce annular parts with relatively simple shapes and large sizes. This method has high flexibility and is suitable for single-piece or small-batch production. For example, in the maintenance of some large mechanical

equipment, if a forged ring of special size needs to be customized, free forging can be adopted.

equipment, if a forged ring of special size needs to be customized, free forging can be adopted.

Product application

Mechanical manufacturing industry

Forged rings are key components in manufacturing various bearings. For example, in large industrial bearings, the outer and inner rings usually adopt forged rings. Through the forging process, the internal microstructure of metal materials can be made more compact, thereby improving the load-bearing capacity and service life of bearings. For high-precision machine tool bearings, after precision processing of forged rings, the rotary accuracy of bearings can be ensured, enabling the machine tool to maintain good stability during working processes such as high-speed cutting.

Aerospace field

In aero engines, forged rings are used to manufacture components of compressors and turbines. These components need to work in an environment of high temperature and high-speed rotation, and have extremely high requirements for the strength, toughness and heat resistance of materials. Forged rings can meet these strict performance requirements and ensure the efficient and stable operation of the engine.

Automobile industry

In a car's transmission, many annular components are manufactured through forging processes. Forged rings can provide precise dimensions and good mechanical properties, ensuring smooth gear shifting of the transmission and improving transmission efficiency. In addition, car wheels also use forged ring technology. This kind of wheel is lightweight and has high strength, which can improve the handling performance and fuel economy of the car.

Energy industry

In wind turbines, the outer ring of the main bearing is usually a forged ring. It needs to withstand huge axial and radial loads and adapt to different climatic conditions. The high strength and high toughness of forged rings can ensure the long-term stable operation of wind turbines in harsh environments. In oil extraction equipment, such as sealing rings and connecting rings of wellhead devices, forged rings also play an important role in ensuring the safety and reliability of equipment.

Rail transit field

In the wheel sets of rail transit vehicles such as trains and subways, the hub part can adopt forged rings. The hub made of forged rings can withstand the huge load during vehicle operation and ensure the reliability and safety of the wheel set. In the transmission system of vehicles, some annular parts such as gearboxes also use forged rings to transmit power and ensure the normal operation of vehicles.

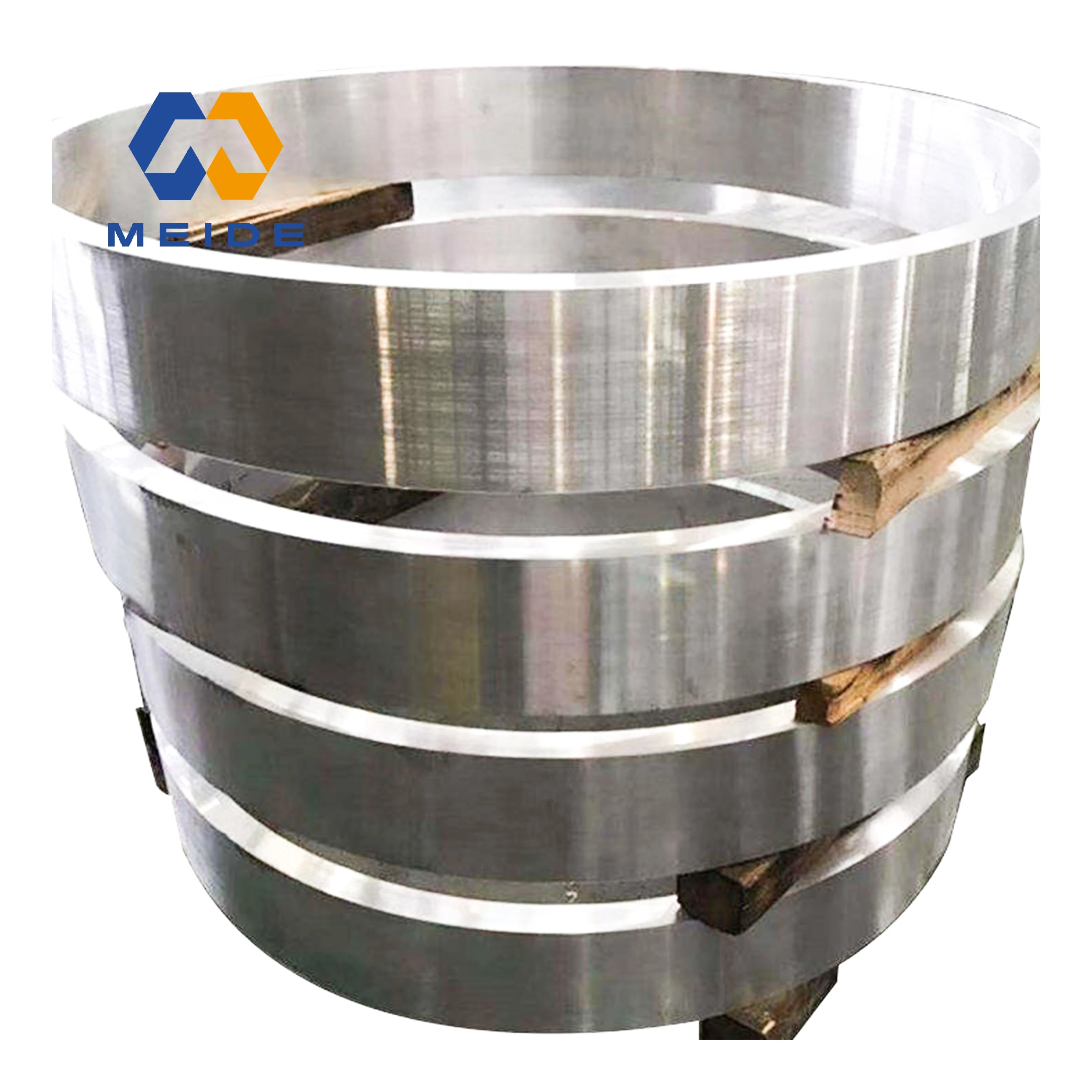

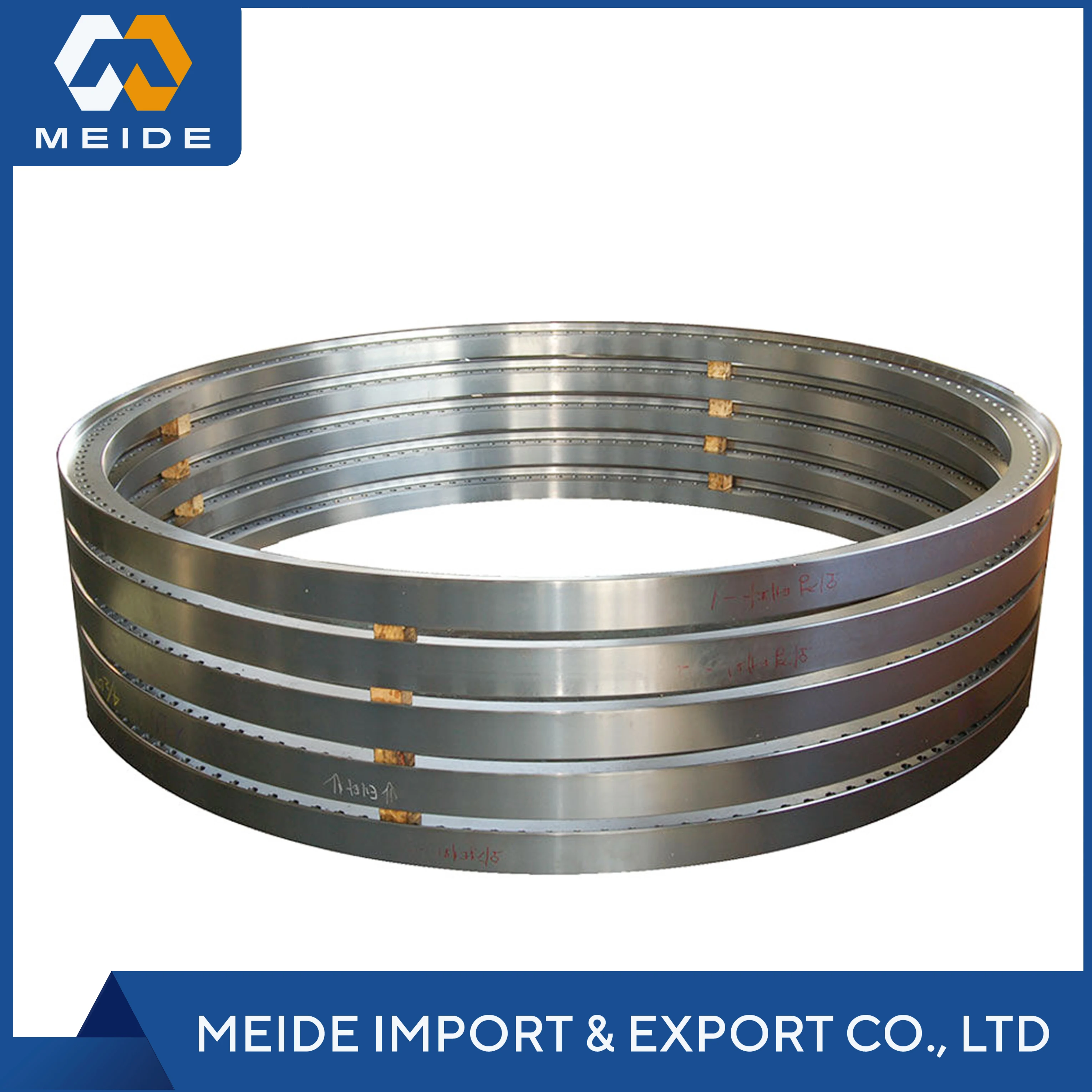

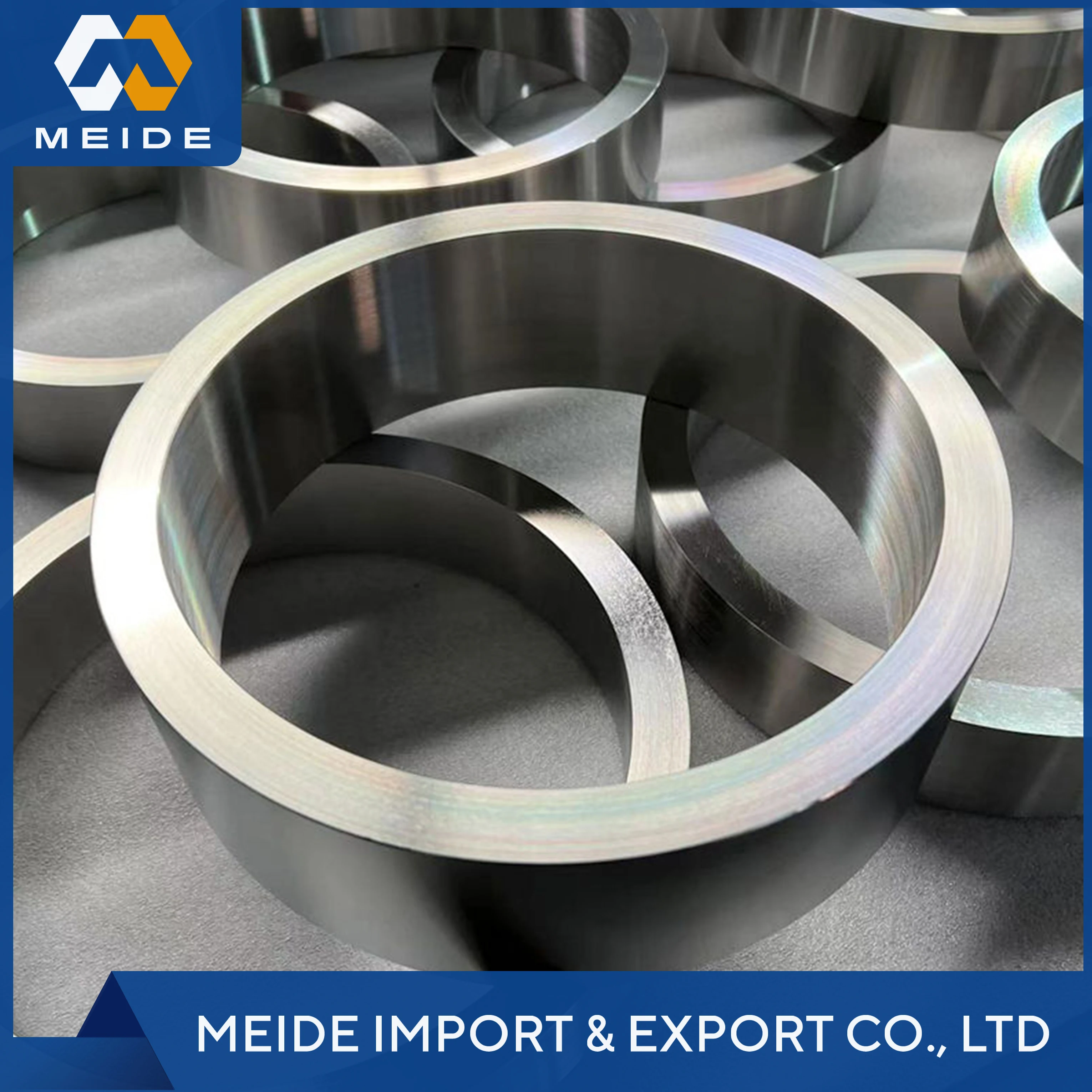

Product Display

Company Profile

Shandong Meide Import and Export Co., LTD was established in 1997. Located in Liaocheng City, Shandong Province, the largest steel logistics center in North China, focusing on the production and sales of copper, aluminum, stainless steel, special steel, mould steel, alloy steel, steel processing machinery and equipment. Our products are mainly extended to five series of plate, strip, tube, bar and profile. We have passed ISO9001:2000 quality system certification, SGS, ROSH, TUV and REACH certification. Has cold rolling, hot rolling and other production lines. Such as heat treatment chemical analysis, metal halide testing, physical testing, nondestructive testing and other testing equipment and testing technology, imported physical and chemical testing equipment full spectrum direct reading spectrometer, can quickly and accurately chemical analysis of all kinds of metal materials. According to American ASTM standard, Japanese JIS standard, German DIN standard, British BS standard and other standards production. At the same time, we can customize and develop new products according to the actual application of customers, and provide products for different cost and performance requirements. The company cooperates with more than 20 well-known steel mills in China, and has established modern large outdoor warehouse and indoor warehouse, with 20,000 tons of goods in stock. The customer base covers all provinces and cities in China, and has more than 100 long-term stable cooperative customers. We warmly welcome and look forward tocooperating with you!

Production Process

Raw material selection and inspection

Select suitable metal materials such as carbon steel, alloy steel, stainless steel, etc. based on the performance requirements and usage environment of the forging ring. Conduct strict quality inspection on selected raw materials, including chemical composition analysis, mechanical property testing (such as tensile testing, hardness testing, etc.), to ensure that the materials meet production standards. For example, for forging rings used in high-strength mechanical components, alloy steel with moderate carbon content and added alloy elements such as chromium and molybdenum may be selected to ensure sufficient strength and toughness. At the same time, it is necessary to check whether the impurity content in the material exceeds the standard to avoid affecting the quality of the forging ring.

Cutting

According to the design size of the forged ring, cut the raw materials into blanks of corresponding specifications. Commonly used blanking methods include sawing and shearing. Sawing is suitable for situations where there is a high requirement for blank size accuracy, the material hardness is relatively large, or the shape is irregular. It can precisely control the length and cross-sectional shape of the blank. Shearing is suitable for blanking blanks with large batches, relatively thin material thickness, and relatively regular shapes. It has high efficiency but relatively lower accuracy compared to sawing. For example, when producing small forged rings in large batches, if the material thickness is within the applicable range of the shearing equipment, shearing blanking can be preferred to improve production efficiency.

Heating

Heat the billet to the appropriate forging temperature range. Different metal materials have different optimal forging temperature ranges, which depend on the crystal structure and phase transition characteristics of the materials. Generally speaking, the forging temperature of carbon steel is around 1000-1250 ℃, while the forging temperature of alloy steel varies depending on its alloy composition. Heating equipment usually uses gas stoves or electric stoves. Gas stoves have a fast heating speed and relatively low cost, making them suitable for large-scale production; Electric furnace heating temperature control is more precise and the heating process is more stable, which is conducive to producing high-quality and high-precision forging rings, but the equipment cost is higher. For example, in fields such as aerospace that require high quality forging rings, electric furnaces are often used to heat the billet to ensure the accuracy and stability of the heating temperature.

Forging:

Free Forging: It covers basic processes such as upsetting (axially compressing the blank to change its shape), punching (punching the center hole according to the requirements of the ring structure), and reaming (increasing the hole diameter to the designed size, which can be done by horse bar reaming or rolling reaming).

Die Forging: First, prepare a mold that meets the shape and size requirements and has sufficient strength and rigidity, then put the blank into the mold cavity, use the press to apply pressure to plastically deform it, and produce a forged ring with high precision and good surface quality, which is suitable for mass production.

Select suitable metal materials such as carbon steel, alloy steel, stainless steel, etc. based on the performance requirements and usage environment of the forging ring. Conduct strict quality inspection on selected raw materials, including chemical composition analysis, mechanical property testing (such as tensile testing, hardness testing, etc.), to ensure that the materials meet production standards. For example, for forging rings used in high-strength mechanical components, alloy steel with moderate carbon content and added alloy elements such as chromium and molybdenum may be selected to ensure sufficient strength and toughness. At the same time, it is necessary to check whether the impurity content in the material exceeds the standard to avoid affecting the quality of the forging ring.

Cutting

According to the design size of the forged ring, cut the raw materials into blanks of corresponding specifications. Commonly used blanking methods include sawing and shearing. Sawing is suitable for situations where there is a high requirement for blank size accuracy, the material hardness is relatively large, or the shape is irregular. It can precisely control the length and cross-sectional shape of the blank. Shearing is suitable for blanking blanks with large batches, relatively thin material thickness, and relatively regular shapes. It has high efficiency but relatively lower accuracy compared to sawing. For example, when producing small forged rings in large batches, if the material thickness is within the applicable range of the shearing equipment, shearing blanking can be preferred to improve production efficiency.

Heating

Heat the billet to the appropriate forging temperature range. Different metal materials have different optimal forging temperature ranges, which depend on the crystal structure and phase transition characteristics of the materials. Generally speaking, the forging temperature of carbon steel is around 1000-1250 ℃, while the forging temperature of alloy steel varies depending on its alloy composition. Heating equipment usually uses gas stoves or electric stoves. Gas stoves have a fast heating speed and relatively low cost, making them suitable for large-scale production; Electric furnace heating temperature control is more precise and the heating process is more stable, which is conducive to producing high-quality and high-precision forging rings, but the equipment cost is higher. For example, in fields such as aerospace that require high quality forging rings, electric furnaces are often used to heat the billet to ensure the accuracy and stability of the heating temperature.

Forging:

Free Forging: It covers basic processes such as upsetting (axially compressing the blank to change its shape), punching (punching the center hole according to the requirements of the ring structure), and reaming (increasing the hole diameter to the designed size, which can be done by horse bar reaming or rolling reaming).

Die Forging: First, prepare a mold that meets the shape and size requirements and has sufficient strength and rigidity, then put the blank into the mold cavity, use the press to apply pressure to plastically deform it, and produce a forged ring with high precision and good surface quality, which is suitable for mass production.

Cool down

There are three ways to control the cooling rate: air cooling (suitable for low carbon steel, etc.), pit cooling (suitable for medium carbon steel, etc.), and furnace cooling (used for cooling sensitive materials such as alloy steel), which are distinguished by cooling speed to prevent defects.

Subsequent processing and handling

Cutting: Further improve the dimensional accuracy and surface quality of forged rings through turning, milling, grinding, etc.

Heat treatment: Quenching, tempering, normalizing, etc. are carried out as needed, such as quenching to increase hardness, tempering to reduce brittleness, normalizing to refine grains, and optimize mechanical properties.

Surface treatment: Use electroplating, spraying, nitriding and other methods to enhance corrosion resistance, wear resistance, etc., such as chrome plating can improve wear resistance and decorativeness.

Quality inspection

Check whether there are defects in the appearance, measure the dimensional accuracy with measuring tools, detect the shape accuracy with instruments, and use methods such as flaw detection to check the internal quality.

There are three ways to control the cooling rate: air cooling (suitable for low carbon steel, etc.), pit cooling (suitable for medium carbon steel, etc.), and furnace cooling (used for cooling sensitive materials such as alloy steel), which are distinguished by cooling speed to prevent defects.

Subsequent processing and handling

Cutting: Further improve the dimensional accuracy and surface quality of forged rings through turning, milling, grinding, etc.

Heat treatment: Quenching, tempering, normalizing, etc. are carried out as needed, such as quenching to increase hardness, tempering to reduce brittleness, normalizing to refine grains, and optimize mechanical properties.

Surface treatment: Use electroplating, spraying, nitriding and other methods to enhance corrosion resistance, wear resistance, etc., such as chrome plating can improve wear resistance and decorativeness.

Quality inspection

Check whether there are defects in the appearance, measure the dimensional accuracy with measuring tools, detect the shape accuracy with instruments, and use methods such as flaw detection to check the internal quality.

Certification

Packaging and Transportation

FAQ

1.What is a forged ring?

Forged rings are metal rings that are made from a forging process. Forging is a manufacturing process that shapes metal by hammering, pressing, or rolling hot metal while it is in a molten state. Forged rings are stronger and more durable than those made by other manufacturing processes.

2.How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

3.Do you provide samples ? is it free or extra ?

Yes, we could offer the sample for free charge but do not pay the cost of freight.

4.Do you have any MOQ?

No limit. More quantity has better price, we will check the best price for you.

5.What's your payment terms?

We adopt Alibaba Trade Assurance, T/T, Paypal, Wester union, etc.

6.What is your packing?

Our packing is 20-25kg for one carton,36 or 48pcs cartons for one pallet. One pallets is about 900-960kg, We also can make customer’s logo on the cartons. Or we customized cartons according to customers’ requirements.

We Recommend

Forged Wheels 5x120

$10.00-30.00

Forged 20mm-150mm Steel Ball for Ball Mill

$715.00-730.00

Half Sphere Dished End for Fire Pits

$600.00-650.00

New Arrivals

New products from manufacturers at wholesale prices