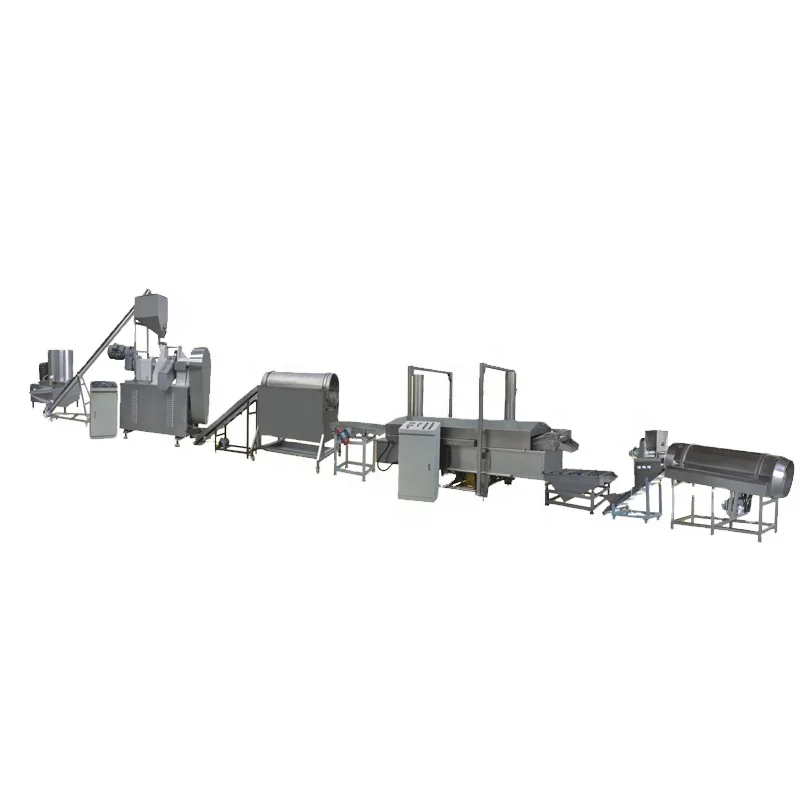

Snack food cheetos kurkure making machine savory snack production line

- Category: >>>

- Supplier: Jinan MT Machinery & Equipment Co. Ltd.Jinan Ltd.

Share on (1601320028345):

Product Overview

Description

Product Description

Kurkure/Cheetos/Nik Naks /Corn Chips making machine processing/production line

The Cheetos\\ corn crisp production line uses corn dregs (corn dregs) as raw materials and is extruded by the host to produce irregular puffed foods. The puffed food can be made into crispy products with different tastes after being seasoned, which is deeply loved by consumers.

The investment for this line is only one tenth of that lager size equipment, especially suitable to small-sized or self owned enterprise.

All the machinery is made of stainless steel. Using the advanced technology for nutrient and instant foodstuff complete lines, the plant is innovative with advanced structure, excellent performance and reliable quality that provide an ideal choice for the investor in foodstuff industry.

All the machinery is made of stainless steel. Using the advanced technology for nutrient and instant foodstuff complete lines, the plant is innovative with advanced structure, excellent performance and reliable quality that provide an ideal choice for the investor in foodstuff industry.

Process flow and equipment configuration

①Fried corn bar production line

Process flow: mixing → feeding → extrusion → deslagging → frying → seasoning → packaging

Equipment configuration: powder mixer → screw conveyor → rotating head extruder → hoist → drum screen → continuous fryer → single drum seasoning line → packaging machine

②Roasted corn bar production line

Process flow: mixing → feeding → squeezing → conveying → baking → seasoning → packaging

Equipment composition: powder mixer → screw conveyor → rotating head extruder → air conveyor → continuous mesh belt oven → single drum seasoning machine

These main equipments are introduced as follows:

Model | Installed power | Real power | Output | Dimension |

MTKC-IF | 134KW | 94KW | 120-150kg/h | 17000*1100*2500mm |

MTKC-IIF | 136KW | 95KW | 200-250kg/h | 17500*1200*2600mm |

MACHINE DETAILS:

High-temperature Roaster

Output: 300-400kg/hr

Effective length of belt: 3.5m

Belt motor power: 0.55kw

Far infrared heater power:

3.9kw x 24

Gas consumption: 6.8m3

Dimension:

4500 x 1500 x 1600mm

Effective length of belt: 3.5m

Belt motor power: 0.55kw

Far infrared heater power:

3.9kw x 24

Gas consumption: 6.8m3

Dimension:

4500 x 1500 x 1600mm

Double Screw Extruder

Output: 120-150kg/hr

Installed power: 4134kw

Actual power: 94kw

Dimension:

1700 x 1100 x 2500mm

Installed power: 4134kw

Actual power: 94kw

Dimension:

1700 x 1100 x 2500mm

Powder Mixer

Output: 300-600kg/hr

Rotary speed: 385rpm

Mixing time: 10min per time

Tank volume:150kg

Power: 4kw

Dimension:

1000 x 630 x 1100mm

Rotary speed: 385rpm

Mixing time: 10min per time

Tank volume:150kg

Power: 4kw

Dimension:

1000 x 630 x 1100mm

Fryer

frying temperature:0~260℃

capacity:200~300㎏/h

size:4500×1350×2350mm;

capacity:200~300㎏/h

size:4500×1350×2350mm;

Our team:

Our company:

Our company(MT Machinery Co., Ltd.'s )has good experience of the industry development. We have well-experienced managers, outstanding engineers as well as well trained techincal workers.By constant

technical exchange with well_known firms of the same line in the world and also by introduction of advanced technique and experience into our company, we have established a strong technical guarantee system. Our company is a manufacturer of puffed extruder and food machinery.

Our products are sold very well throughout China and are also introduced to Southeast Asia, East Europe, Africa and other regions. Our market share is increasing each year.

Customer

Feedback

Certifications

Packing & Delivery

About packing fully automatic pet food machine making/pet dog food making machine:

We can pack according to customer requirements.

Our Services

1. Pre-sale services: Act as a good adviser and assistant of clients, enable them to get rich and generous returns on their investments.

(1)Select equipment model;

(2)According to the special requirements of customers, free project planning and design services are provided;

(3)Train technical personnel for clients.

2. Services during the sale: Respect clients, devote ourselves to improving the total value of clients.

(1)Pre-check and accept products ahead of delivery;

(2)Help clients to draft solving plans.

3.After-sale services: Provide considerate services to maximize customers’ benefits.

(1)Assist clients to prepare for the first construction scheme;

(2)Install and debug the equipment;

(3)Train the first-line operators;

(4)Examine the equipment;

(5)Take initiative to eliminate the troubles rapidly;

(6)Provide manuals for installation, operation and maintenance

(7)Provide equipment CAD drawings;

(8)Provide technical exchanging.

(9)1 year complete warranty.

(1)Select equipment model;

(2)According to the special requirements of customers, free project planning and design services are provided;

(3)Train technical personnel for clients.

2. Services during the sale: Respect clients, devote ourselves to improving the total value of clients.

(1)Pre-check and accept products ahead of delivery;

(2)Help clients to draft solving plans.

3.After-sale services: Provide considerate services to maximize customers’ benefits.

(1)Assist clients to prepare for the first construction scheme;

(2)Install and debug the equipment;

(3)Train the first-line operators;

(4)Examine the equipment;

(5)Take initiative to eliminate the troubles rapidly;

(6)Provide manuals for installation, operation and maintenance

(7)Provide equipment CAD drawings;

(8)Provide technical exchanging.

(9)1 year complete warranty.

FAQ

1. Are you a manufaturer or a trading company?

We are a professional manufaturer with trading department.

2. Could we visit your company to check the machine?

Of course! Highly appreciated your visit to our company.

3. How about your noodle machine quality?

All main parts of the machine are made of 304 stainless steel. We will be responsible for site installation and commissioning. Ifthere is anything wrong with the machine, our engineers can be on site to repair it within two days. Even if the machine doesn't break down. We also pay a return visit twice a year by video phone.

Our payment terms is 30% T/T as down payment, 70% by irrevocable L/C at sight before delivering.

5. What’s your Guarantee?

We provide 1 year complete Guarantee and life-time maintenance service.

6. How about the installation?

We will dispatch our engineers to your factory to guide you installation and commissioning work and training your operator.

7. Why Choose us as a reliable Processing line supplier?

(1) Advantage technology; (2) High quality material; (3) Tight quality control; (4) Accurate maching; (5) 7 - 24 hours service

We Recommend

New Arrivals

New products from manufacturers at wholesale prices