Xinmao Good Price 5 Gallon Water Bottle Filling Machine 20 Liter Washing Filling Machine

- Category: >>>

- Supplier: Zhangjiagang City Xinmao Drink Machinery Co. Ltd.Zhangjiagang Ltd.

Share on (1601322257901):

Product Overview

Description

Automatic 5 Gallon Water Barrel Production Line / 20 Liter Water Filling Machine For Purified Mineral Water

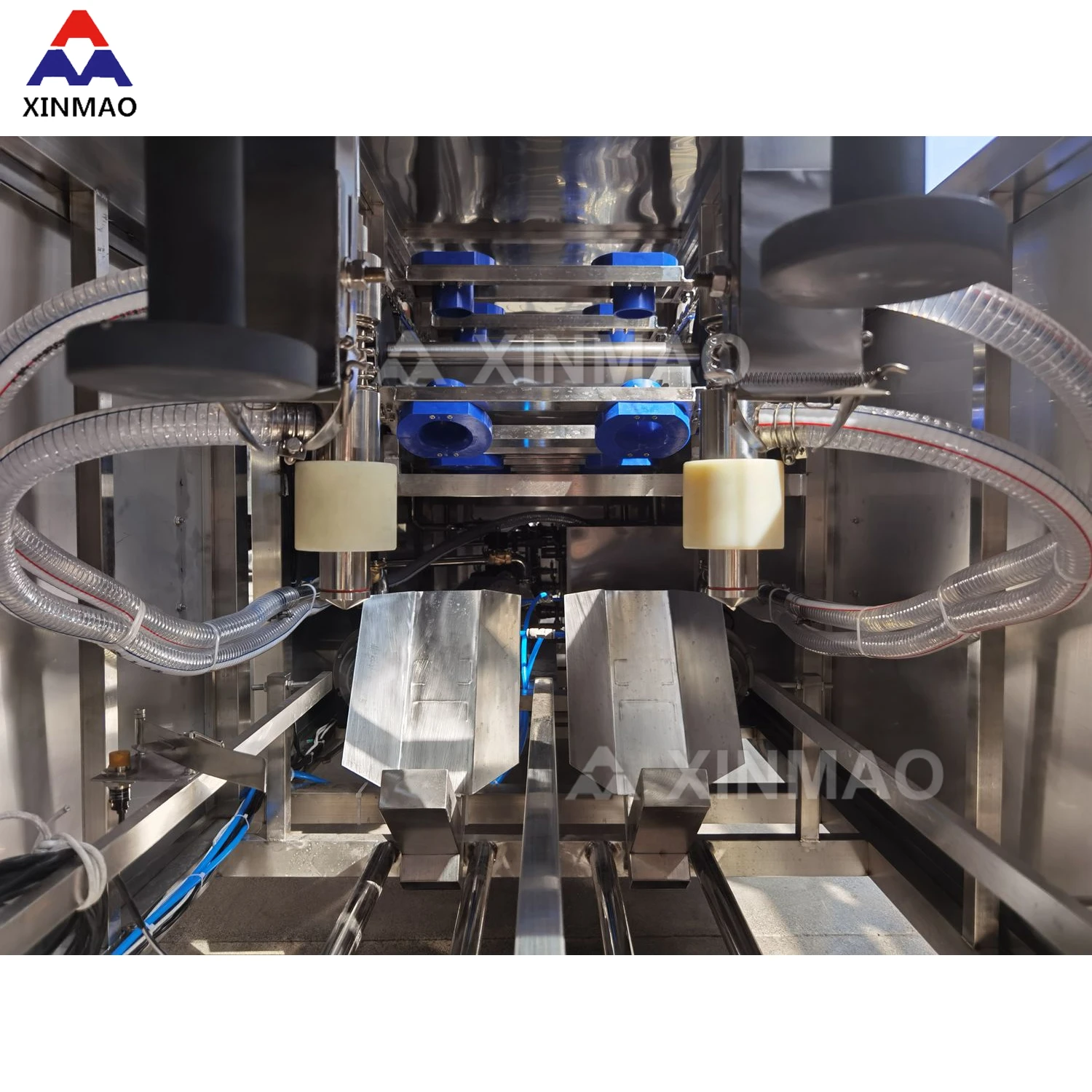

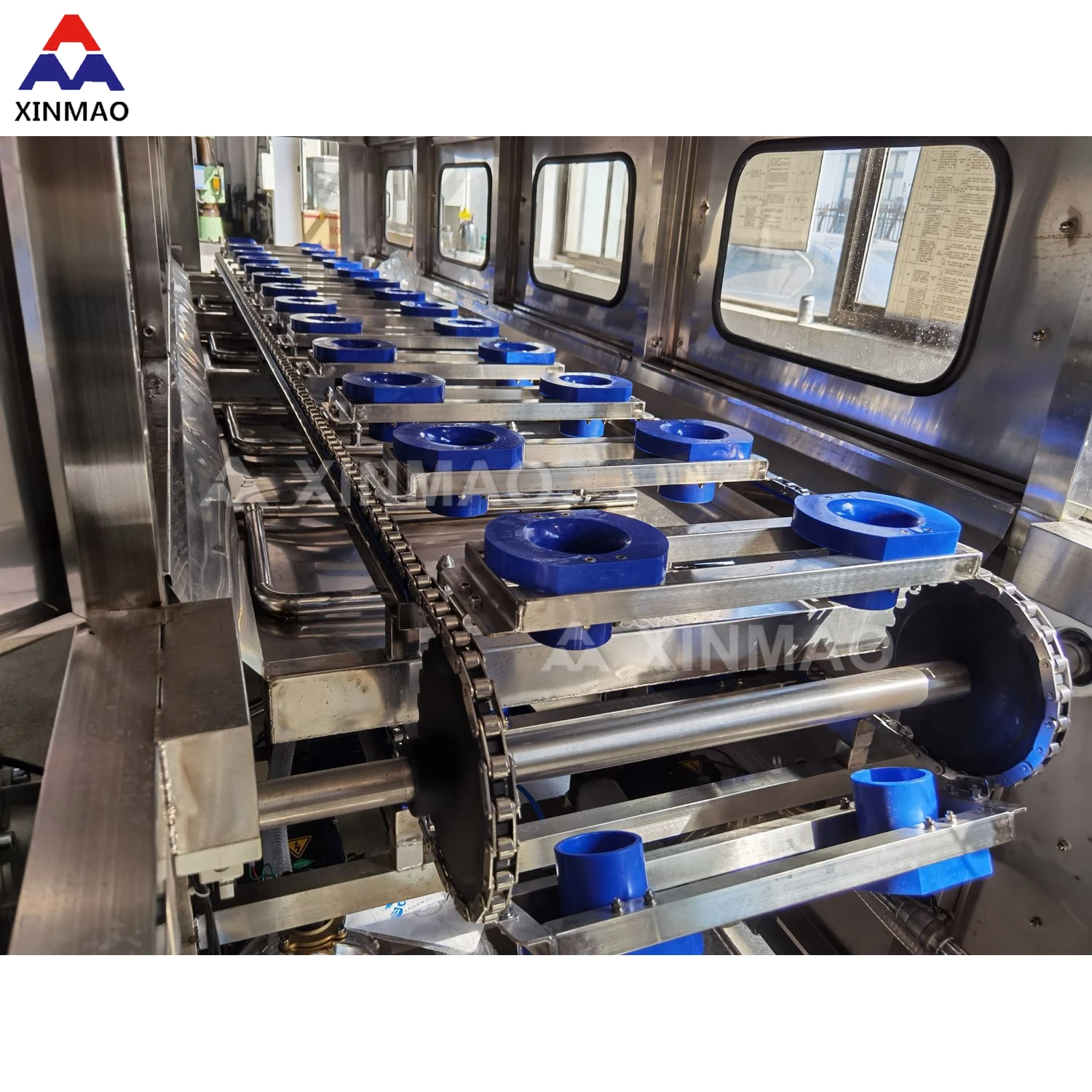

XINMAO QGF series 5 gallon filling machine is designed for producing 5 gallon barrel drinking water.This machine is consisted of rinser,filler and capper. The rinser has several sprays which can be used as for both clean water rinsing and disinfectant rinsing. The disinfectant can be recycled. The machine also has automatic capping device, and cap rinsing device. The wholeproduction line can automatic feeding barrel, rinsing, sterilizing, filling, capping, counting and output.QGF barrel production line is specially used for 5 Gallon barrel drinking water. This machine integrates washing/filling/capping into one unit. It is the good ideal for produce the mineral water/distilled water/pure water equipments. Whole machines are adopt the high quality stainless steel, It's erosion proof ability is strong, easy to washing.

Product Paramenters

Model | QGF-120/150 | QGF-200 | QGF-300 | QGF--450 | QGF-600 | QGF-900 | QGF-1200 |

Speed | 120/150BPH | 200BPH | 300BPH | 450BPH | 600BPH | 900BPH | 1200BPH |

Power | 1.38KW | 1.75KW | 3KW | 4KW | 7.5KW | 9.75KW | 13.5KW |

Weight | 680KG | 800KG | 1500KG | 2100KG | 3000KG | 3500KG | 4500KG |

Related Products

1. Water Treatment System

According to customer's raw water analysis report and the final water standard request, we will suggest customer to choose the

suitable water treatment system.

suitable water treatment system.

2.Semi-Automatic Blow Molding Machine

Semi-auto PET bottle blowing machine plastic bottle blow molding machineis suitable for producing PET plastic containers and

bottles. It is widely used to produce the carbonated bottle, mineral water,carbonated drink bottle, pesticide bottle oil bottle

cosmetics,wide-mouth bottle etc.

bottles. It is widely used to produce the carbonated bottle, mineral water,carbonated drink bottle, pesticide bottle oil bottle

cosmetics,wide-mouth bottle etc.

3.Automatic Palletizing Machine For Barreled Water Filling Supporting Gantry Palletizing Equipment

In the increasingly tense situation in view of the labor, the drinking water treatment works, a large labor force resources, etc.,we are manufacturer for drinking water (water) of actual demand, in development and production of new type of numerical control for 3 to 5 gallons bottled water and automatic palletizing equipment through continuous improvement innovation, thus enable the equipment to achieve higher performance-price ratio, the equipment covers an area of less, low operating cost, Per hour can be 1200 barrels (output can be customized) bottled water according to the requirements of one to three layers (each layer 4*4=16 barrels can be customized multiple specifications), in order to facilitate transportation and storage, the whole equipment can be easily operated by one person, to a great extent, reduce the labor intensity of employees and reduce the entire production line staffing.

Main technical features:

1, the use of slide type self-gravity bucket, server state zero power consumption, low energy consumption; The built-in proximity signal detection mechanism automatically adjusts the palletizing speed according to the output to achieve matching with the filling bottle line.

2, the bucket system adopts the new design pneumatic opposite type bucket clip, does not hurt the barrel mouth and shrink film,does not drop the barrel, the gas consumption is small.

3, lifting system adopts linear bearing slider type soft connection structure, the equipment lifting speed is stable, the accident of mechanical failure protection mechanism and other functions, effectively ensure the protection function of the machine under special fault.

4. The machine can stack 1-3 layers, and the number of stacking layers can be adjusted arbitrarily on the touch screen to meet the different needs of customers.

5, manipulator lifting, translation position using numerical control technology detection and positioning, bucket, bucket position is quite concise and accurate, avoid the high fault rate caused by the excessive use of positioning switch. The bucket adopts servo system, the bucket in the process of lifting and translation at high, low and medium speed operation (low speed bucket clamping - high speed operation - low speed bucket unloading), so as to make the whole operation process coordinated, smooth operation.

6, the machine adopts microcomputer control, man-machine interface operation, running parameters and action process can be freely adjusted on the touch screen, with fault stop, alarm, and other functions.

7. Photoelectric detection and protection switch is set at the lifting and lifting position of the machine. When the machine is running, if abnormal phenomenon is detected at the detection part, the machine will stop immediately and alarm, which protects the safety of production personnel and equipment to a large extent.

Main technical features:

1, the use of slide type self-gravity bucket, server state zero power consumption, low energy consumption; The built-in proximity signal detection mechanism automatically adjusts the palletizing speed according to the output to achieve matching with the filling bottle line.

2, the bucket system adopts the new design pneumatic opposite type bucket clip, does not hurt the barrel mouth and shrink film,does not drop the barrel, the gas consumption is small.

3, lifting system adopts linear bearing slider type soft connection structure, the equipment lifting speed is stable, the accident of mechanical failure protection mechanism and other functions, effectively ensure the protection function of the machine under special fault.

4. The machine can stack 1-3 layers, and the number of stacking layers can be adjusted arbitrarily on the touch screen to meet the different needs of customers.

5, manipulator lifting, translation position using numerical control technology detection and positioning, bucket, bucket position is quite concise and accurate, avoid the high fault rate caused by the excessive use of positioning switch. The bucket adopts servo system, the bucket in the process of lifting and translation at high, low and medium speed operation (low speed bucket clamping - high speed operation - low speed bucket unloading), so as to make the whole operation process coordinated, smooth operation.

6, the machine adopts microcomputer control, man-machine interface operation, running parameters and action process can be freely adjusted on the touch screen, with fault stop, alarm, and other functions.

7. Photoelectric detection and protection switch is set at the lifting and lifting position of the machine. When the machine is running, if abnormal phenomenon is detected at the detection part, the machine will stop immediately and alarm, which protects the safety of production personnel and equipment to a large extent.

Latest XINMAO News

09/05/2023

Customers from Uzbekistan came to our factory visit the water production line.

10/16/2023

Customers from Malaysia came to visit the production line of sports cap juice.

04/15/2024

Customers from Uzbekistan came to our factory to check their can carbonated drink production line.

04/28/2024

Customers from Mozambique came to our factory to place an order of the juice production line.

05/15/2024

Good evaluations of Xinmao Machinery by UAE user.

07/29/2024

Customers from South Africa came to our factory to check their juice production line.

08/02/2023

XINMAO 60-60-15 18000bph carbonated drink line for glass bottle.

4/18/2024

XINMAO PET bottle blow molding machine and water filling machine, shipped to Mexico.

05/09/2024

XINAMO auto 4000bph carbonated drink line for PET bottle, shipped to Algeria.

6/2/2024

XINMAO 20-4 6500CPH can carbonated drink line,shipped to Uzbekistan.

6/18/2024

XINMAO 24-24-8 10000BPH juice production line,shipped to Turkmenistan.

07/30/2024

XINMAO 6000bph water filling line for PET bottle, shipped to Nigeria.

Company Profile

ZHANGJIAGANG CITY XINMAO DRINK MACHINERY CO., LTD

We are a professional manufacturing and trading Combo, who is specializing in the research, development and production of various water and beverage machinery. XINMAO has standard workshop more than 6000 square meters, and more than 18 years of technical and practical experience in helping customers set up water and beverage production lines in their factory.

Factory Display

FAQ

Q For a new starter, how can you help me start and run a water or beverage bottling plant?

A We can help you do the bottle design,label design and choose the suitable labeling and package type according to your localmarket. If you have confirm the factory size, we can also make the machine layout design accordingly. We can help you install themachines, train your staff how to operate, maintain the machines and even help you hire experienced Chinese engineer to work inyour factory as a production manager.

Q What is the guarantee or warranty of your machines?

A We give 18 months warranty for the mechanical parts and 12 months warranty for the electric parts.

Q How can we check our machines if we order the machines from you?

A We will test all the machines before shipment, you can come to inspect the machines or we can take videos for you.

Q How can I know the quality of your machines before I order?

A We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories

and see the machines running. You are also very welcome to visit our company in China to see the machine running in our factory.

Q Can your company provide turnkey project from A to Z?

A Yes, we can provide the turnkey project for beverage production line, from PET preform and cap making machine, PET bottle blowing machine, water treatment plant, juice or carbonated drink mixing plant, filling and packing machines.

Q What is the guarantee or warranty of your machines?

A We give 18 months warranty for the mechanical parts and 12 months warranty for the electric parts.

Q How can we check our machines if we order the machines from you?

A We will test all the machines before shipment, you can come to inspect the machines or we can take videos for you.

Q How can I know the quality of your machines before I order?

A We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories

and see the machines running. You are also very welcome to visit our company in China to see the machine running in our factory.

Q Can your company provide turnkey project from A to Z?

A Yes, we can provide the turnkey project for beverage production line, from PET preform and cap making machine, PET bottle blowing machine, water treatment plant, juice or carbonated drink mixing plant, filling and packing machines.

09/05/2023

Customers from Uzbekistan came to our factory visit the water production line.

10/16/2023

Customers from Malaysia came to visit the production line of sports cap juice.

05/15/2024

Good evaluations of Xinmao Machinery by UAE user.

08/02/2023

XINMAO 60-60-15 18000bph carbonated drink line for glass bottle.

10/21/2023

XINMAO 5Gallon bottling line shipping to USA.

05/09/2024

XINAMO auto 4000bph carbonated drink line for PET bottle, shipped to Algeria.

Automatic 5 Gallon Liquid Production Line / 20 Liter Water Filling Machine For Purified Mineral Water

XINMAO QGF series 5 gallon filling machine is designed for producing 5 gallon barrel drinking water.This machine is consisted of rinser,filler and capper. The rinser has several sprays which can be used as for both clean water rinsing and disinfectant rinsing. The disinfectant can be recycled. The machine also has automatic capping device, and cap rinsing device. The wholeproduction line can automatic feeding barrel, rinsing, sterilizing, filling, capping, counting and output.QGF barrel production line is specially used for 5 Gallon barrel drinking water. This machine integrates washing/filling/capping into one unit. It is the good ideal for produce the mineral water/distilled water/pure water equipments. Whole machines are adopt the high quality stainless steel, It's erosion proof ability is strong, easy to washing.

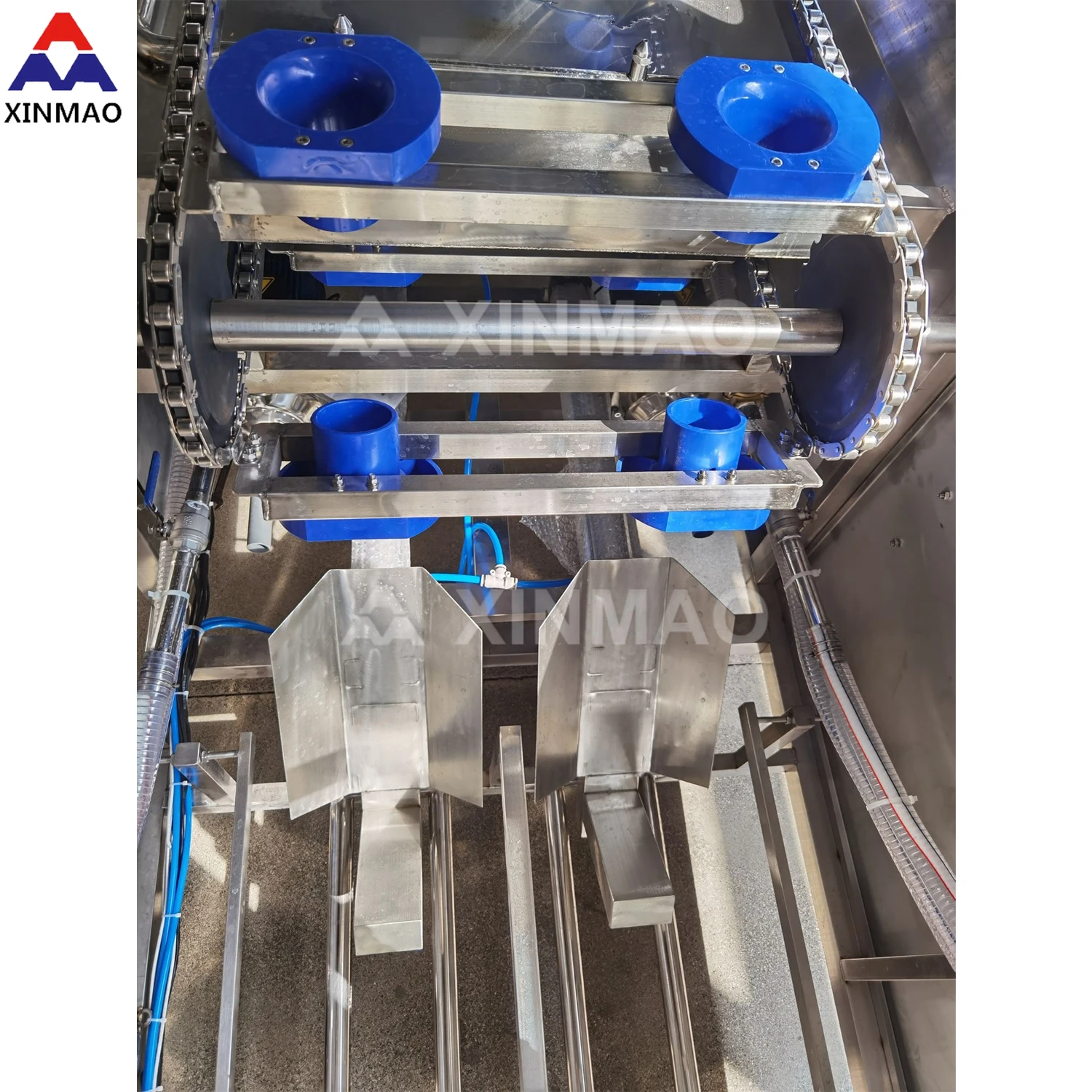

Cap Decapper

This model automatic decapper is special equipment for 5-gallon retrieving barrel. It does not damage caps. It adopts computer

control and its capacity can be adjusted.Cap pulling organism from AIRTAC adopt pneumatic adjustment, which solves the problems oftolerance of barrel height and tolerance of barrel's mouth.And increases cap pulling success greatly. 304 stainless machine frame and machine body.

control and its capacity can be adjusted.Cap pulling organism from AIRTAC adopt pneumatic adjustment, which solves the problems oftolerance of barrel height and tolerance of barrel's mouth.And increases cap pulling success greatly. 304 stainless machine frame and machine body.

Brusher Part

Function: clean the inside and outside of 5 gallon bottles with brush and water.

1. Rotary style to wash the bottle body.

2. Material of machine frame and body: all 304 Stainless Steel.

3. All 304 stainless steel pipeline , valve and connector, fine polish, no death corner

4. Linear washing style with ø350brush 1pc ø200 brush 3pcs 300*3 brush 20pcs

5. Water pump: with 304 stainless steel pump

1. Rotary style to wash the bottle body.

2. Material of machine frame and body: all 304 Stainless Steel.

3. All 304 stainless steel pipeline , valve and connector, fine polish, no death corner

4. Linear washing style with ø350brush 1pc ø200 brush 3pcs 300*3 brush 20pcs

5. Water pump: with 304 stainless steel pump

Washing Part

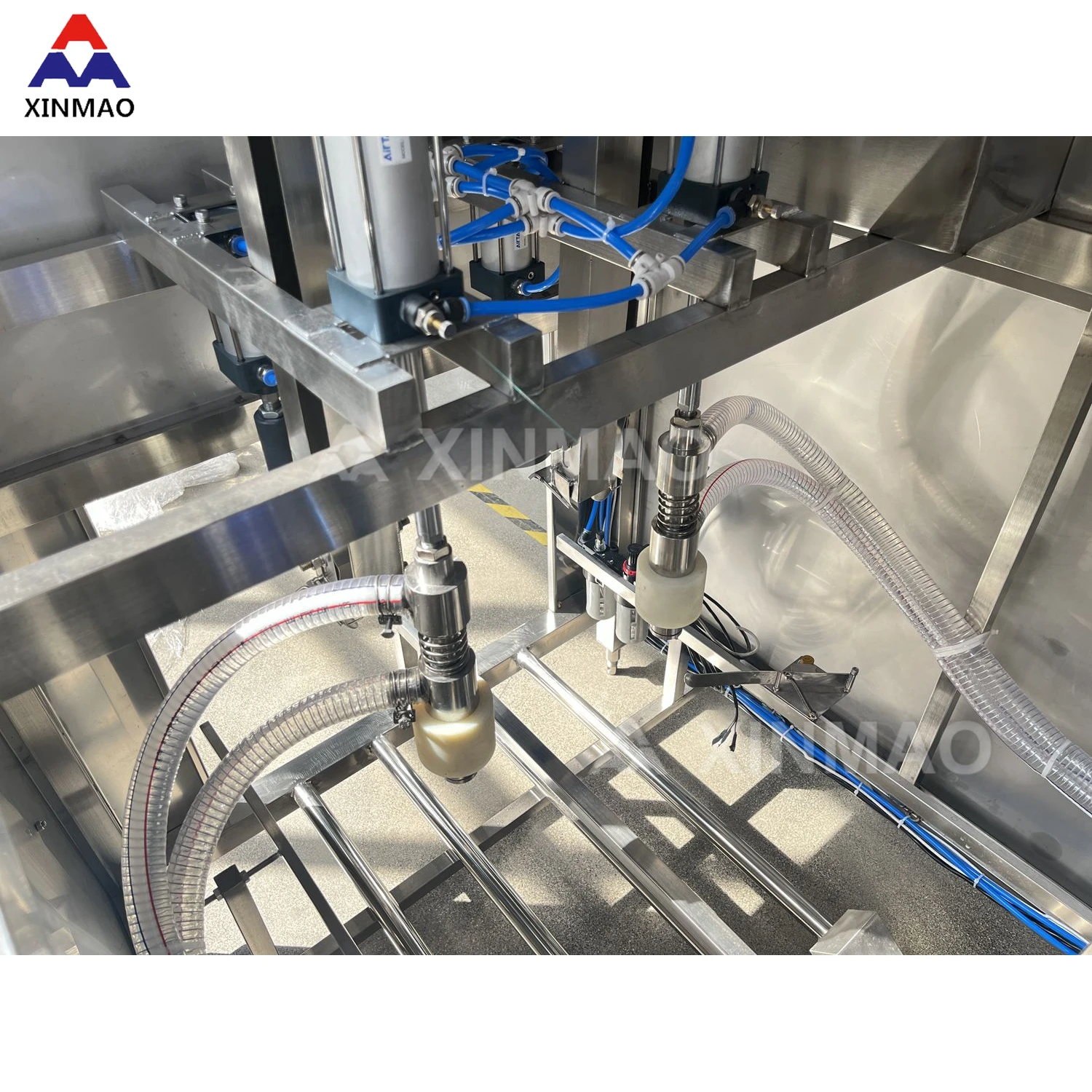

Filling Part

Capping Part

Online cap washer

Capping machine

Buffering Position

Product Paramenters

Model | QGF-150 | QGF-300 | QGF--450 | QGF-600 | QGF-900 |

Speed | 150BPH | 300BPH | 450BPH | 600BPH | 900BPH |

Power | 5.3KW | 5.3KW | 8KW | 10.6KW | 15.9KW |

Compressed Air | 0.4-0.6mpa | 0.4-0.6mpa | 0.4-0.6mpa | 0.4-0.6mpa | 0.4-0.6mpa |

Inside washing | 18S*1 | 18S*1 | 18S*1 | 18S*1 | 18S*1 |

Outside washing | 18S*1 | 18S*1 | 18S*1 | 18S*1 | 18S*1 |

Related Products

Water Treatment System

This water treatment system is made by the

raw water tank through the pretreatment to

reverse osmosis desalting device to get pure

water. Pretreatment is by silica sand filter,

activated carbon filter, sodium ion exchanger

and the precision filter composition. The

reverse osmosis device the core parts adopt

the world famous water pump and reverse

osmosis RO membrane. With a full set of

membrane and washing device.

raw water tank through the pretreatment to

reverse osmosis desalting device to get pure

water. Pretreatment is by silica sand filter,

activated carbon filter, sodium ion exchanger

and the precision filter composition. The

reverse osmosis device the core parts adopt

the world famous water pump and reverse

osmosis RO membrane. With a full set of

membrane and washing device.

Semi-Automatic PET Bottle Blow Molding Machine

The machine is also equipped with muffler and oiling system to lubricate the mechanical

part of the machine.It is very popular and well used in beverages,cosmetics,pharmaceutical industry.

part of the machine.It is very popular and well used in beverages,cosmetics,pharmaceutical industry.

Automatic Palletizing Machine For Barreled Water Filling Supporting Gantry Palletizing Equipment

In the increasingly tense situation in view of the labor, the drinking water treatment works, a large labor force resources, etc.,we are manufacturer for drinking water (water) of actual demand, in development and production of new type of numerical control for 3 to 5 gallons bottled water and automatic palletizing equipment through continuous improvement innovation, thus enable the equipment to achieve higher performance-price ratio, the equipment covers an area of less, low operating cost, Per hour can be 1200 barrels (output can be customized) bottled water according to the requirements of one to three layers (each layer 4*4=16 barrels can be customized multiple specifications), in order to facilitate transportation and storage, the whole equipment can be easily operated by one person, to a great extent, reduce the labor intensity of employees and reduce the entire production line staffing.

Main technical features:

1, the use of slide type self-gravity bucket, server state zero power consumption, low energy consumption; The built-in proximity signal detection mechanism automatically adjusts the palletizing speed according to the output to achieve matching with the filling bottle line.

2, the bucket system adopts the new design pneumatic opposite type bucket clip, does not hurt the barrel mouth and shrink film,does not drop the barrel, the gas consumption is small.

3, lifting system adopts linear bearing slider type soft connection structure, the equipment lifting speed is stable, the accident of mechanical failure protection mechanism and other functions, effectively ensure the protection function of the machine under special fault.

4. The machine can stack 1-3 layers, and the number of stacking layers can be adjusted arbitrarily on the touch screen to meet the different needs of customers.

5, manipulator lifting, translation position using numerical control technology detection and positioning, bucket, bucket position is quite concise and accurate, avoid the high fault rate caused by the excessive use of positioning switch. The bucket adopts servo system, the bucket in the process of lifting and translation at high, low and medium speed operation (low speed bucket clamping - high speed operation - low speed bucket unloading), so as to make the whole operation process coordinated, smooth operation.

6, the machine adopts microcomputer control, man-machine interface operation, running parameters and action process can be freely adjusted on the touch screen, with fault stop, alarm, and other functions.

7. Photoelectric detection and protection switch is set at the lifting and lifting position of the machine. When the machine is running, if abnormal phenomenon is detected at the detection part, the machine will stop immediately and alarm, which protects the safety of production personnel and equipment to a large extent.

Main technical features:

1, the use of slide type self-gravity bucket, server state zero power consumption, low energy consumption; The built-in proximity signal detection mechanism automatically adjusts the palletizing speed according to the output to achieve matching with the filling bottle line.

2, the bucket system adopts the new design pneumatic opposite type bucket clip, does not hurt the barrel mouth and shrink film,does not drop the barrel, the gas consumption is small.

3, lifting system adopts linear bearing slider type soft connection structure, the equipment lifting speed is stable, the accident of mechanical failure protection mechanism and other functions, effectively ensure the protection function of the machine under special fault.

4. The machine can stack 1-3 layers, and the number of stacking layers can be adjusted arbitrarily on the touch screen to meet the different needs of customers.

5, manipulator lifting, translation position using numerical control technology detection and positioning, bucket, bucket position is quite concise and accurate, avoid the high fault rate caused by the excessive use of positioning switch. The bucket adopts servo system, the bucket in the process of lifting and translation at high, low and medium speed operation (low speed bucket clamping - high speed operation - low speed bucket unloading), so as to make the whole operation process coordinated, smooth operation.

6, the machine adopts microcomputer control, man-machine interface operation, running parameters and action process can be freely adjusted on the touch screen, with fault stop, alarm, and other functions.

7. Photoelectric detection and protection switch is set at the lifting and lifting position of the machine. When the machine is running, if abnormal phenomenon is detected at the detection part, the machine will stop immediately and alarm, which protects the safety of production personnel and equipment to a large extent.

Real Picture Of Customer Factory

Company Profile

About XINMAO MACHINERY

Zhangjiagang City Xinmao Drink Machinery Co.,Ltd. founded at 2005.Itd is located at Jinfeng Economic Development Zone Of

Zhangjiagang City. The company has more than 17 years of production practice experience and absorbs advanced technology at home and abroad. Our company is a professional manufacturer integrating research,development,and production of various water,juice,soda,and can beverage machinery.We are a leading enterprise in research and production of beverage filling and packingmachines. we also supply turnkey project according to customers’ request, including workshop design, machine layout design,water,gas, electic cable layout design, label and bottle design.

Zhangjiagang City. The company has more than 17 years of production practice experience and absorbs advanced technology at home and abroad. Our company is a professional manufacturer integrating research,development,and production of various water,juice,soda,and can beverage machinery.We are a leading enterprise in research and production of beverage filling and packingmachines. we also supply turnkey project according to customers’ request, including workshop design, machine layout design,water,gas, electic cable layout design, label and bottle design.

XINMAO Factory Shipment

Factory Display

FAQ

Q For a new starter, how can you help me start and run a water or beverage bottling plant?

A We can help you do the bottle design,label design and choose the suitable labeling and package type according to your localmarket. If you have confirm the factory size, we can also make the machine layout design accordingly. We can help you install themachines, train your staff how to operate, maintain the machines and even help you hire experienced Chinese engineer to work inyour factory as a production manager.

Q What is the guarantee or warranty of your machines?

A We give 18 months warranty for the mechanical parts and 12 months warranty for the electric parts.

Q How can we check our machines if we order the machines from you?

A We will test all the machines before shipment, you can come to inspect the machines or we can take videos for you.

Q How can I know the quality of your machines before I order?

A We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories

and see the machines running. You are also very welcome to visit our company in China to see the machine running in our factory.

Q Can your company provide turnkey project from A to Z?

A Yes, we can provide the turnkey project for beverage production line, from PET preform and cap making machine, PET bottle blowing machine, water treatment plant, juice or carbonated drink mixing plant, filling and packing machines.

Q What is the guarantee or warranty of your machines?

A We give 18 months warranty for the mechanical parts and 12 months warranty for the electric parts.

Q How can we check our machines if we order the machines from you?

A We will test all the machines before shipment, you can come to inspect the machines or we can take videos for you.

Q How can I know the quality of your machines before I order?

A We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories

and see the machines running. You are also very welcome to visit our company in China to see the machine running in our factory.

Q Can your company provide turnkey project from A to Z?

A Yes, we can provide the turnkey project for beverage production line, from PET preform and cap making machine, PET bottle blowing machine, water treatment plant, juice or carbonated drink mixing plant, filling and packing machines.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices