1220X2440mm 2mm to 25mm Waterproof Brown Black Anti Slip Film Faced Plywood for Constructions and Building

- Category: >>>

- Supplier: Waying Trading (nanning) Co. Ltd.Waying Ltd.

Share on (1601323346721):

Product Overview

Description

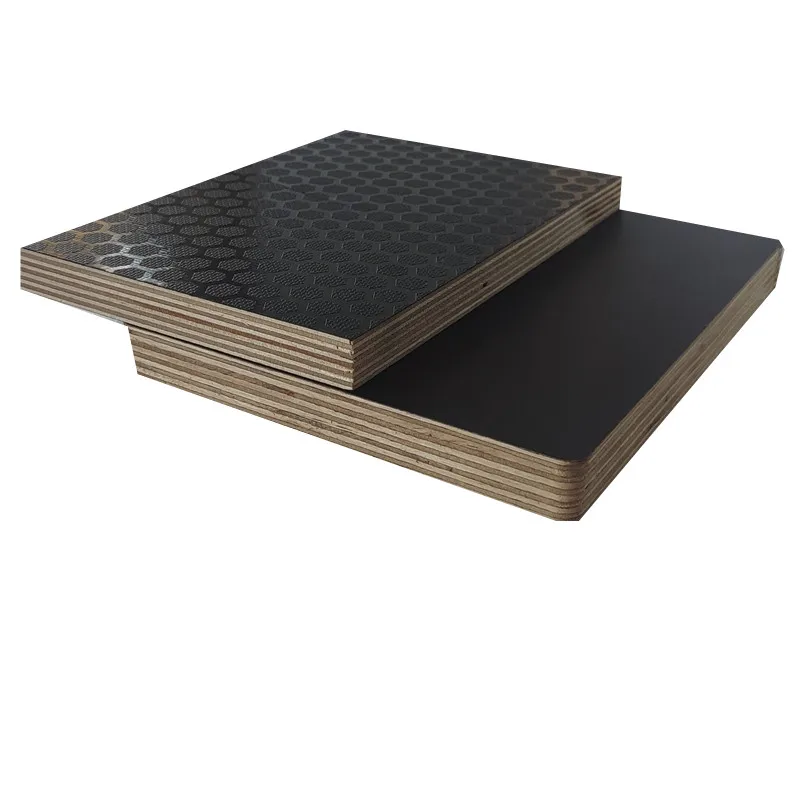

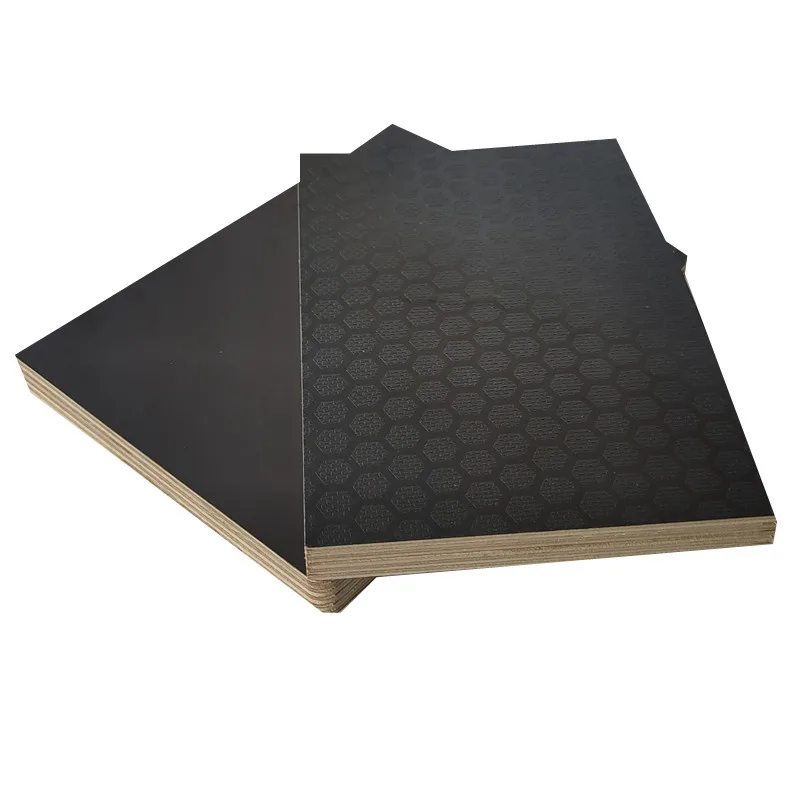

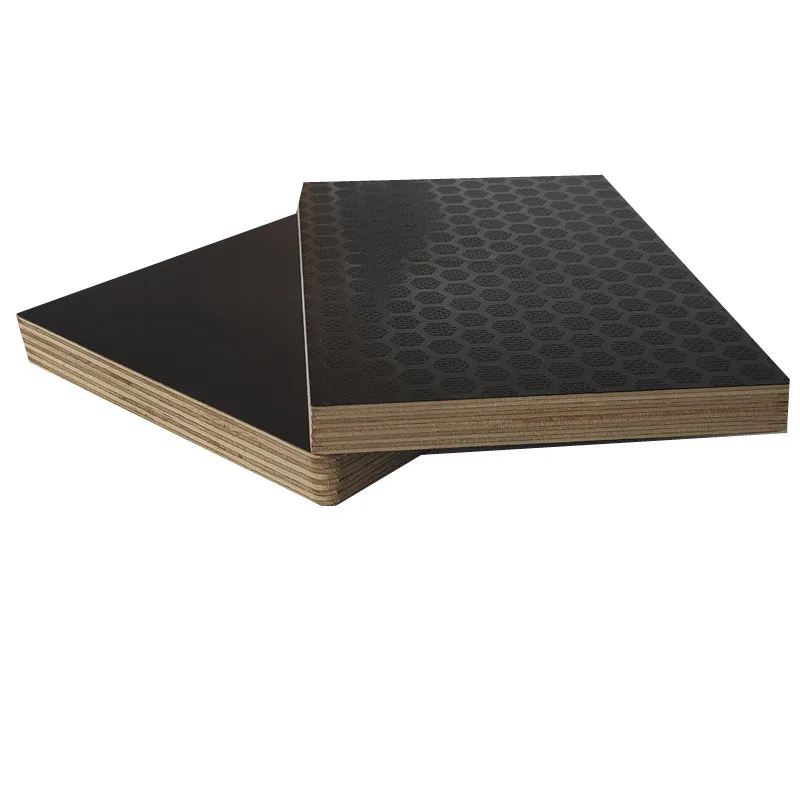

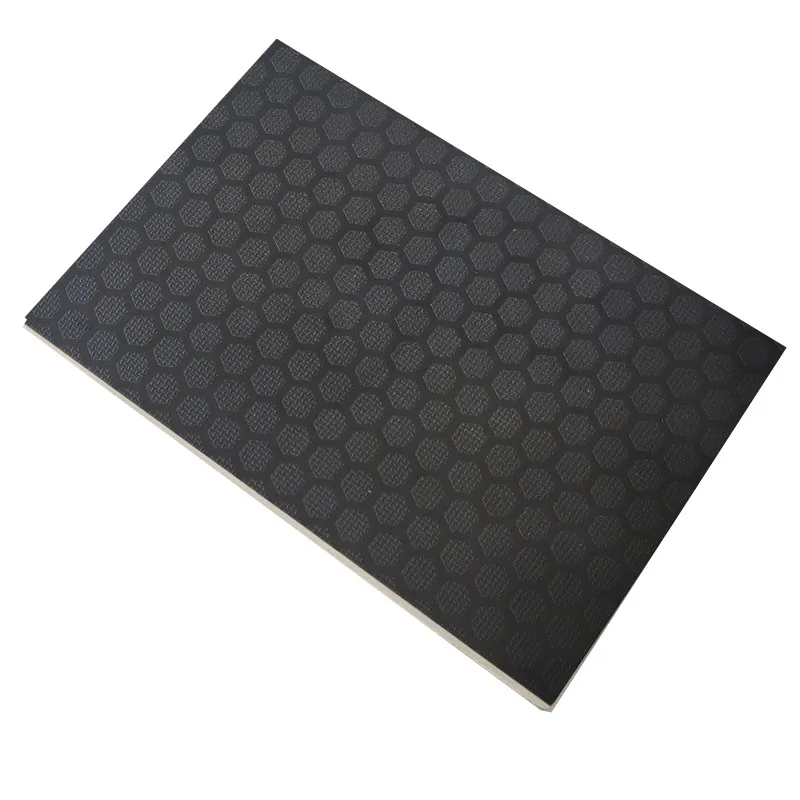

High quality wbp glue wire mesh rice hexagon 9mm 12mm 15mm 18mm 20mm 25mm 30mm black brown anti slip film face plywood for flight cases stage truck floor,ect.

Anti- slip plywood - non slip plywood- high quality

Slip-Resistant Flooring Plywood

Wide range of high-quality, decorative surfaces

Phenolic Resin Faced Non-Slip Plywoods

Hexagon Pattern / Mesh Pattern / Rice Pattern

These anti-slip plywood products are available in a range of decorative surface coverings, each pattern offering slightly different characteristics.The raised slip-resistant pattern maintains its anti-slip properties under a wide range of climatic conditions.

The panels are used extensively in the manufacture and repair of vehicles and flight cases, the installation of stagings & disabled access ramps.They can be used wherever a flooring surface is required to be slip-resistant.

Product Name: | Plywoods |

F&B Film: | Brown,Black,Red |

Grade: | A / B |

Core: | Eucalyptus,Birch,Combi,Hardwood,Okoume,etc. |

Glue: | WBP Penolic,WBP Melamine |

Thickness: | 2mm-30mm |

Specifications: | Normal size: 1220mmx2440mm,1250mmx2500mm,1530x3150mm |

Package: | Standard Seaworthy packing |

Inner Packing: Pallet is wrapped with a 0.20mm plastic paper | |

Loading: | 20'GP: 8pallets/22cbm |

Certificates: | LR, ISO9001, ISO14001 |

MOQ: | 40pcs |

Price terms: | FOB, CNF, CIF |

Payment: | T/T, 100% irrevocable L/C at sight |

Delivery time: | Within 20 days after receipt of the original L/C or the 30% advanced payment |

Supply capacity: | 3000CBM/Month |

Usages: | Commonly used in the manufacture of flight cases and for decorative effects such as stage truck floor |

More Details: | Density: 400-880kgs/m3 |

Product display

About Production

Use fresh full core and assemble different layers of veneers in different direction to guarantee the high strength and smooth flat surface of the plywood.

Using glue according to the material and climate to make sure the bonding strength of the boards improve by 20%.

To use waterproof and wear resistant phenolic glue which make it high temperature resistant, low temperature resistant, acid and alkali resistant and stable performance.

Surface of the boards is very flat and smooth, also its high density and average thickness makes it not easy to adsorb the concrete while easy to disassemble, thus to save the construction time and can have more turning over times.

47 steps for the full production progress and 8 checking steps- looking, touching, turning over, beating, pressing, pushing, sawing and steaming to control the quality strictly and don't even one piece of board to enter into the market.

We purchase the raw material in bulk, manufacture in our own factory by our experienced workers and sell directly from our factory to make sure the lowest cost and price with good quality.

Production Process

Our Advantages

1.We manufacture "fit to purpose" products which satisfy specific requirements in terms of size, composition, thickness,functionality and performance with competitive price and timely delivery.

2.Located in the largest plywood manufacturing base of China---NanNing, Guangxi province, the raw material is enough and various, and our company supply you sufficient products of complete ranges.

3. We have been providing products for well-know brands- Mitsubishi and Otis for six years, so the quality is reliable.

4. With a long business history, our products are greatly welcomed in China, Japan, Korea, Canada, Australia, South East Asia, Americas, Africa, Eastern Europe and other countries and regions.

5.Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Packaging & Shipping

Inner Packing: Packing the plywood sheets on the wooden pallets wrapped with strong plastic bags.

Outer Packing: Packing the pallets with thick cartons and tied tightly with steel strips.

Packing: Sea worthy packing. Goods be packed on pallets, wrapped with plastic bags, tied tightly with packing belt and then packedwith cartons.

FAQ

1. Are you a factory or trading company?

We're a factory who can supply you high quality products with competitive prices, as well as timely delivery and considerable service.

2. What products you can supply?

We can supply Filn faced plywood,Commercial Plywood, Furniture Plywood, Marine Plywood, Packing Plywood, Film Faced Plywood, Melamine Faced Plywood/MDF/Chipboard, LVL and Pine Scaffolding Boards.

3. How can I get a sample?

We offer free samples but I'm afraid you have to pay for the courier charge, that is a fair business way for both of us.

4. How do you guarantee the quality of the products?

a. We're a FSC and SGS certificated plywood manufacturer with 20 years' experience and we use the best material for all the products.

b. Our workers are very skilled and they are responsible for their job and products. Professional workers are working for their own production process.

c. All the machines in our factory are the most advanced.

d. Our production manager will strictly contol every steps of production.

e. Each piece of board will be carefully checked by our QC before they leave our factory.

f. Also we welcome our clients or their friends to come to our factory to check the quality.

5. What is your payment term?

Commonly we do T/T(30% deposit to confirm the order and start production, 70% balance payment after shipment against copy of B/L), T/T can save much time and money than L/C, but if it is relatively a big amount, we also can accept 100% irreocable L/C.

6. When you can ship the goods out?

Usually we can make the delivery in 15-20 days after receiving your 30% advance payment, but it may take few more days if we meet holidays, such as Chinese New Year Holidays.

Certifications

Why choose us?

1, More than 12 years of professional experience, 70 skilled workers can, the capacity 60HQ every month.

2, We are not a large factory, but we will keep every promise firmly.

3, Superior quality wins us the trust from clients, quality first is always our tenet. We refine every details strictly.

4, Creation and innovation are critical for meeting the increasing demands of customers.

5, Good communication gurantees best understanding and lowest deviation.

6, Delivery on time will be ensured

If you are interested in our plywood,please feel free to let us know.

CONTACT US

Lisa Huang

Mail: nnwymy04(at)nnwymy.com

Mob&Whatsapp&Wechat: +86 18277173270

Tel / Fax:+86 771-2022657

Waying Trading (Nanning) Co., Ltd.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices