Durable PVC ABS PU PP PC Injection Mold Electronic Product Shell Plastic Moulds in Shenzhen

- Category: >>>

- Supplier: Shenzhen Tairuixin Precision Mold Co. Ltd.Shenzhen Ltd.

Share on (1601323464736):

Product Overview

Description

Products Description

Name | Moluld Cavity/Core | |||||||

Mould core | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed | |||||||

Mould base | LKM, HASCO, DME or upon customer's requirement | |||||||

Type of plastic mold | 3-plate mold,2-plate mold,2K molds;over-molding molds;stack molds; | |||||||

stack molds | Single/Multi 1*11+11*2,1+1+1,etc | |||||||

Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve,banana gate | |||||||

Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc | |||||||

Runner | Hot/cold type | |||||||

Plastic material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEl, and PES | |||||||

Mould life | 300,000-1,000,000 shots | |||||||

Lead time | 15-35days after deposit received | |||||||

Specification | Follow the 3D final drawing | |||||||

Packaging details | air transport | Apply transparent anti rust oil, wrap with plastic wrap, and pack in wooden boxes. | ||||||

Railway transportation | The anti rust oil for the mold cavity should be wrapped in special plastic wrap and then vacuum packed. Re enter the wooden crate. | |||||||

sea transportation | The anti rust oil for the mold cavity should be wrapped in special plastic wrap and then vacuum packed. Re enter the wooden crate. | |||||||

Product packaging

FAQ

Frequently Asked Questions about Injection Molding Industry

Q1. What is injection molding?

A:A process where molten plastic is injected into a mold to create parts. Offers advantages like producing complex shapes, high efficiency, and suitable for large-scale production. Uses injection molding machines with components like hopper, heating system,injection unit, and clamping system.

Q2. What's “cycle time”?

A:Total time for one injection molding process, including injection, cooling, and part removal. Also can involve mold temperature adjustment and material preparation. Influenced by material, complexity, mold design, and cooling system. Optimize by improving cooling and process parameters.

Q3. Common defects and prevention?

A:Defects: voids (low pressure/uneven flow), warping (uneven cooling), short shots (under-filling), weld lines (material meet). Prevent by adjusting pressure/temperature, controlling material dryness, improving mold design/cooling,increasing injection speed/pressure, optimizing temperature/speed.

Q4. How to choose plastic material?

A:Consider mechanical properties (strength/durability), thermal properties (heat resistance), chemical resistance, and cost. Materials like ABS, PC, POM, PA, PP have specific characteristics and uses. Also consider environmental factors.

Q5. Important mold design factors?

A:Material (steel for high-volume, aluminum for prototypes). Ensure even material flow and cooling. Venting for gas escape. Maintenance and different mold structures.

Q6. Ensure product quality?

A:Mold validation, process control, real-time monitoring, inspection. Follow standards. Correct non-conforming products

Q1. What is injection molding?

A:A process where molten plastic is injected into a mold to create parts. Offers advantages like producing complex shapes, high efficiency, and suitable for large-scale production. Uses injection molding machines with components like hopper, heating system,injection unit, and clamping system.

Q2. What's “cycle time”?

A:Total time for one injection molding process, including injection, cooling, and part removal. Also can involve mold temperature adjustment and material preparation. Influenced by material, complexity, mold design, and cooling system. Optimize by improving cooling and process parameters.

Q3. Common defects and prevention?

A:Defects: voids (low pressure/uneven flow), warping (uneven cooling), short shots (under-filling), weld lines (material meet). Prevent by adjusting pressure/temperature, controlling material dryness, improving mold design/cooling,increasing injection speed/pressure, optimizing temperature/speed.

Q4. How to choose plastic material?

A:Consider mechanical properties (strength/durability), thermal properties (heat resistance), chemical resistance, and cost. Materials like ABS, PC, POM, PA, PP have specific characteristics and uses. Also consider environmental factors.

Q5. Important mold design factors?

A:Material (steel for high-volume, aluminum for prototypes). Ensure even material flow and cooling. Venting for gas escape. Maintenance and different mold structures.

Q6. Ensure product quality?

A:Mold validation, process control, real-time monitoring, inspection. Follow standards. Correct non-conforming products

.

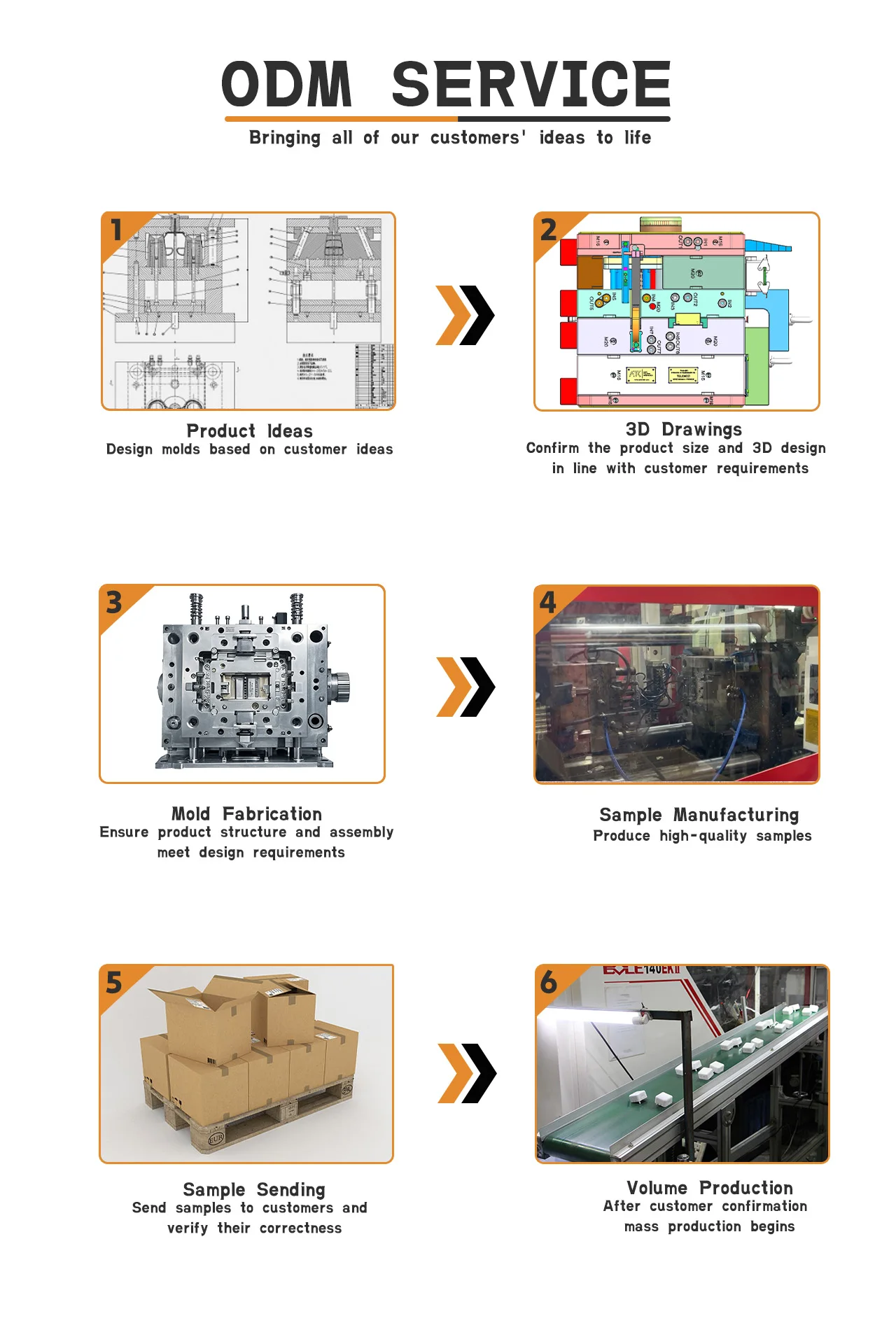

Q7. Handle custom requirements?

A:Quick mold changes, material adjustments, pilot production. Communicate with customers.

Q7. Handle custom requirements?

A:Quick mold changes, material adjustments, pilot production. Communicate with customers.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices