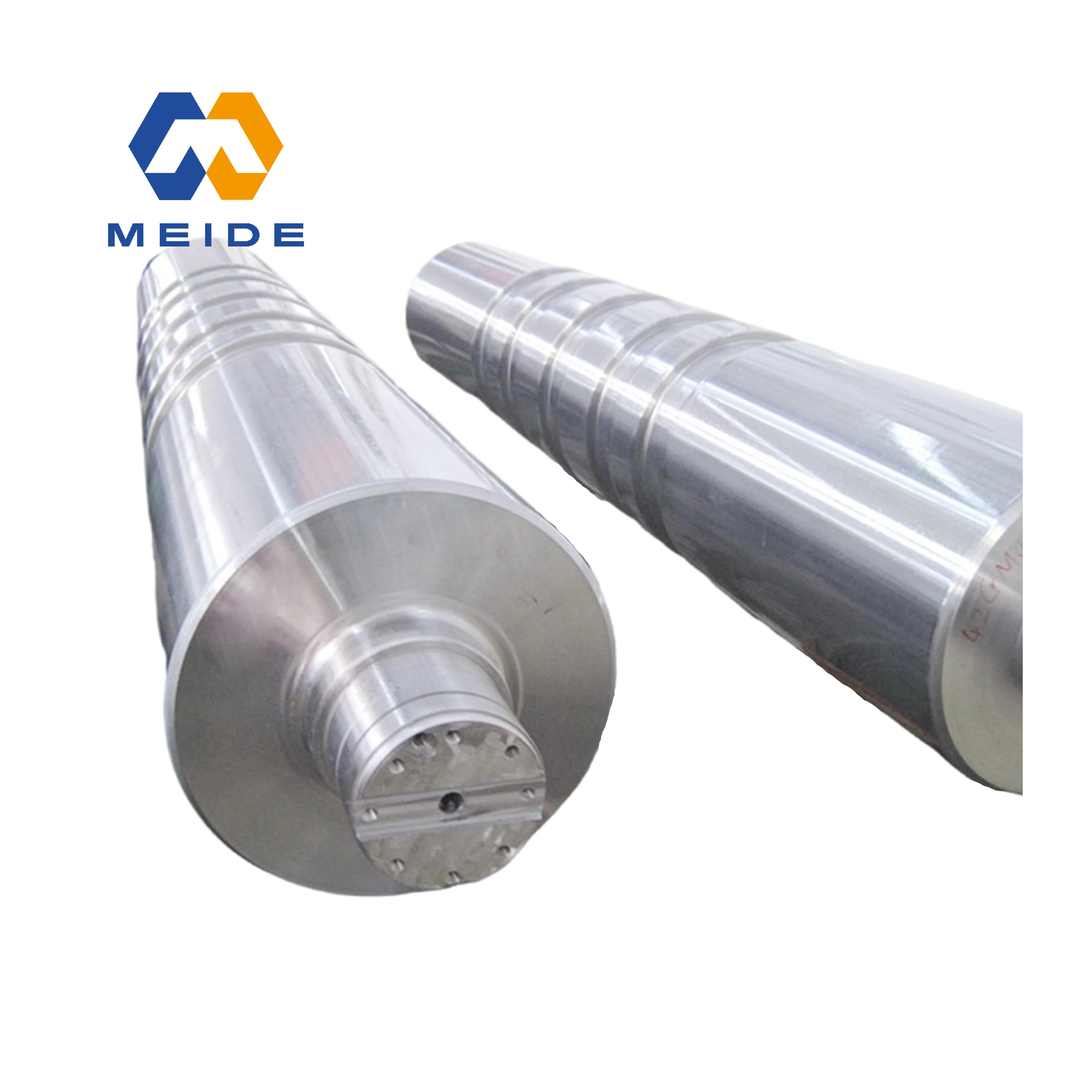

20crni2mo 30crnimo8 Forged Main Shaft Steel Forging Step Forged Shaft Corrugated Rollers

- Category: >>>

- Supplier: Shandong Meide Import And Export Co. Ltd.Shandong Ltd.

Share on (1601324440712):

Product Overview

Description

Product specification

Place of Origin | Shandong,China |

Brand Name | Meide |

Product | Forged shaft |

Size range | OD100-1000mm |

Length | max length 6000mm |

Production | procedure Hot forging |

Raw material | Ingot |

Delivery condition | Forging +quenching /tempering +machining according to the drawing |

Heat treatment | Normalizing,Quenching and tempering |

Keyword | Open Die Forging Parts |

Packing | Wooden Case |

M0Q | 10pcs |

Product overview

Forging shaft is by heating the metal to a plastic state, using a tool such as a press or forging hammer to plastic deformation of the metal, so as to obtain the required shape and size of the shaft parts. The forging process can significantly improve the internal structure of the metal, improve the mechanical properties and wear resistance of the metal, so that the forging shaft can still maintain stable performance in the harsh working environment.

Product characteristics

High strength: the forging process makes the internal structure of the metal more dense, and improves the tensile strength and yield strength of the shaft.

High reliability: The forged shaft has good fatigue resistance and impact resistance, and can maintain stable performance under long time and high load working conditions.

Good physical properties: Forged shaft has excellent wear resistance, corrosion resistance and high temperature resistance, suitable for a variety of complex working environments.

Precise shape and size: The forging process can precisely control the shape and size of the shaft to meet the needs of various precision machinery and equipment.

High reliability: The forged shaft has good fatigue resistance and impact resistance, and can maintain stable performance under long time and high load working conditions.

Good physical properties: Forged shaft has excellent wear resistance, corrosion resistance and high temperature resistance, suitable for a variety of complex working environments.

Precise shape and size: The forging process can precisely control the shape and size of the shaft to meet the needs of various precision machinery and equipment.

Product application

1. Automobile industry

Drive shaft: In the car's transmission system, the drive shaft is used to transfer the power of the engine to the wheels, and its high strength and high reliability are the key to ensure the normal operation of the vehicle.

Transaxle shaft: In the transaxle of the car, the forged shaft also plays an important role, responsible for transferring power from the differential to the wheels.

2. Aerospace

Engine shaft parts: In aero engines, forged shafts are used to connect key components such as turbines and compressors to withstand the harsh environment of high temperature, high pressure and high-speed rotation.

Landing gear shafts: Forged shafts are also used extensively in aircraft landing gear systems to ensure the stability and reliability of the landing gear.

3. Mechanical manufacturing

Machine tool spindle: Machine tool spindle is the core part of the machine tool, its accuracy and stability directly affect the processing quality. Because of its high strength and good physical properties, forged shaft is widely used in the manufacture of machine tool spindles.

Transmission shaft: In various transmission devices, such as gearboxes, reducers, etc., forged shafts are used to transmit power and torque.

4. Wind power and energy

Wind turbine spindle: In the field of wind power, the spindle of a wind turbine is a key component that connects the generator and the impeller, and needs to withstand a large amount of wind and torque. Forged shafts are widely used in this field because of their excellent mechanical properties and stability.

Hydraulic generator shaft: A forged shaft is also used in hydraulic generators to transfer the power generated by the water flow to the generator.

Drive shaft: In the car's transmission system, the drive shaft is used to transfer the power of the engine to the wheels, and its high strength and high reliability are the key to ensure the normal operation of the vehicle.

Transaxle shaft: In the transaxle of the car, the forged shaft also plays an important role, responsible for transferring power from the differential to the wheels.

2. Aerospace

Engine shaft parts: In aero engines, forged shafts are used to connect key components such as turbines and compressors to withstand the harsh environment of high temperature, high pressure and high-speed rotation.

Landing gear shafts: Forged shafts are also used extensively in aircraft landing gear systems to ensure the stability and reliability of the landing gear.

3. Mechanical manufacturing

Machine tool spindle: Machine tool spindle is the core part of the machine tool, its accuracy and stability directly affect the processing quality. Because of its high strength and good physical properties, forged shaft is widely used in the manufacture of machine tool spindles.

Transmission shaft: In various transmission devices, such as gearboxes, reducers, etc., forged shafts are used to transmit power and torque.

4. Wind power and energy

Wind turbine spindle: In the field of wind power, the spindle of a wind turbine is a key component that connects the generator and the impeller, and needs to withstand a large amount of wind and torque. Forged shafts are widely used in this field because of their excellent mechanical properties and stability.

Hydraulic generator shaft: A forged shaft is also used in hydraulic generators to transfer the power generated by the water flow to the generator.

Product Display

Company Profile

Shandong Meide Import and Export Co., LTD was established in 1997. Located in Liaocheng City, Shandong Province, the largest steel logistics center in North China, focusing on the production and sales of copper, aluminum, stainless steel, special steel, mould steel, alloy steel, steel processing machinery and equipment. Our products are mainly extended to five series of plate, strip, tube, bar and profile. We have passed ISO9001:2000 quality system certification, SGS, ROSH, TUV and REACH certification. Has cold rolling, hot rolling and other production lines. Such as heat treatment chemical analysis, metal halide testing, physical testing, nondestructive testing and other testing equipment and testing technology, imported physical and chemical testing equipment full spectrum direct reading spectrometer, can quickly and accurately chemical analysis of all kinds of metal materials. According to American ASTM standard, Japanese JIS standard, German DIN standard, British BS standard and other standards production. At the same time, we can customize and develop new products according to the actual application of customers, and provide products for different cost and performance requirements. The company cooperates with more than 20 well-known steel mills in China, and has established modern large outdoor warehouse and indoor warehouse, with 20,000 tons of goods in stock. The customer base covers all provinces and cities in China, and has more than 100 long-term stable cooperative customers. We warmly welcome and look forward to cooperating with you!

Production Process

Material preparation: Select suitable metal materials, such as carbon steel, alloy steel, stainless steel, etc., and pre-treatment, such as cutting, heating, etc.

Forging molding: The heated metal material is put into the forging mold, and the plastic deformation is carried out by tools such as a press or forging hammer to obtain the required shape and size of the shaft parts.

Heat treatment: Heat treatment of forged shaft parts to eliminate internal stress, improve hardness and wear resistance.

Finishing The shaft parts after heat treatment are finished, such as turning, grinding, etc., to achieve the required dimensional accuracy and surface finish.

Inspection and acceptance: The shaft parts after finishing are inspected and accepted to ensure that the product quality meets the relevant standards and requirements.

Forging molding: The heated metal material is put into the forging mold, and the plastic deformation is carried out by tools such as a press or forging hammer to obtain the required shape and size of the shaft parts.

Heat treatment: Heat treatment of forged shaft parts to eliminate internal stress, improve hardness and wear resistance.

Finishing The shaft parts after heat treatment are finished, such as turning, grinding, etc., to achieve the required dimensional accuracy and surface finish.

Inspection and acceptance: The shaft parts after finishing are inspected and accepted to ensure that the product quality meets the relevant standards and requirements.

Certification

Packaging and Transportation

FAQ

1.Q:What is a forged shaft?

A:Forged steel shafts are created through a manufacturing process that involves the shaping of the shaft Forgings using localized compressive forces.

A:Forged steel shafts are created through a manufacturing process that involves the shaping of the shaft Forgings using localized compressive forces.

2.Q:What are the advantages of forged shafts?

A:Forging shafts can improve the metal's organizational structure and mechanical properties, ensuring that the parts have good mechanical properties and a longer service life.

3.Q:Material selection for forged shafts?

A:The materials used for forging shafts are mainly carbon steel and alloy steel of various compositions, followed by aluminum, magnesium, copper, titanium and their alloys.

4.Q:What are the process flows for forging shafts?

A:Taking hot die forging as an example, the general sequence is: blanking, heating, roll forging, die forging, trimming, punching, correction, intermediate inspection, heat treatment of forgings, cleaning, correction and inspection.

5.Q:What are the classifications of forging temperatures?

A:According to the different forging temperatures, it can be divided into hot forging (above 800℃), warm forging or semi-hot forging (between 300-800℃) and cold forging (performed at room temperature).

We Recommend

Forged Wheels 5x120

$10.00-30.00

Forged 20mm-150mm Steel Ball for Ball Mill

$715.00-730.00

Half Sphere Dished End for Fire Pits

$600.00-650.00

New Arrivals

New products from manufacturers at wholesale prices