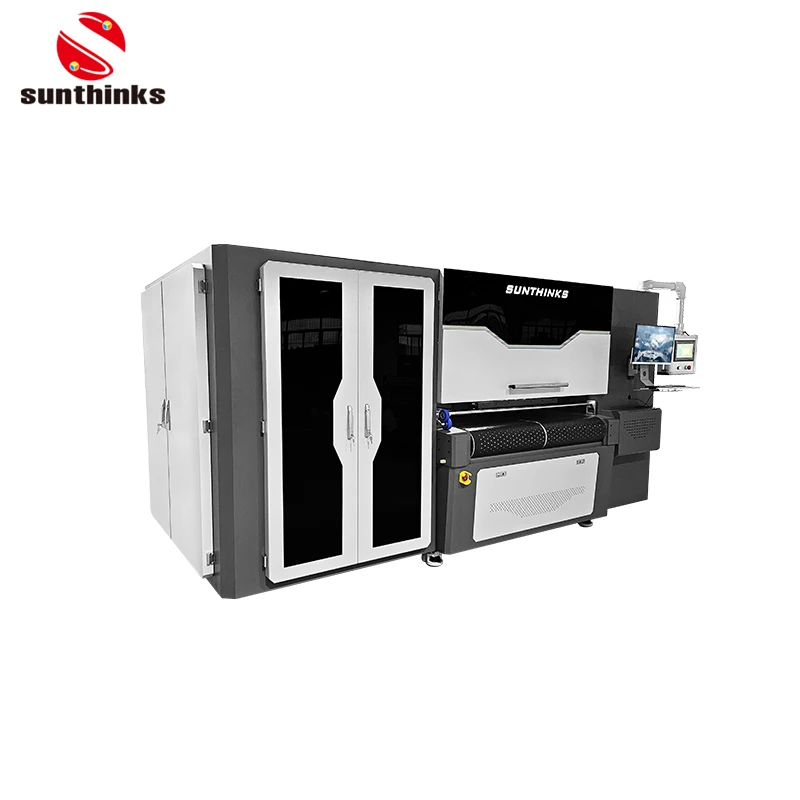

Sunthinks SU805 Large Size Digital Single Pass UV Printer For Acrylic/Plastic/Metal/Wood Printing

- Category: >>>

- Supplier: Shenzhen Yuxunda Electronics Co. Ltd.Shenzhen Ltd.

Share on (1601324461403):

Product Overview

Description

Product Paramenters

Product Name | 805mm Large Format Single Pass UV Printer |

Brand | Sunthinks |

Printer Model | SU805 |

Printhead Model | Epson UV Printhead |

Printhead Quantity | 28pcs or 35pcs |

Colors | (C+M+Y+K)*7 or (C+M+Y+K + W)*7 |

Ink | UV Ink |

Printing Size | Max 805mm |

Power | 7.0kw |

Feeding Width | 1600mm |

Product Weight | 1600kg |

Printer Size | 3550mm*2250mm*1810mm |

Feeding Height | Max 100mm |

Printing Speed | 50m/min |

Application | Stainless Steel,Iron Sheet,Plastic Bag,Acrylic,Hollow Board,Coated Paper,Leather,Wood Board,Glass,Ceramic Tile,Corrugated Board,Canvas,Non-Woven Bag, Etc. |

Customized Service | Yes |

Auto Feeder | Optional |

After-Sales Service | 24/7 Online Service/Lifetime After-Sales/Engineer On-Site Service |

Picture Display

Product Features

All Sunthinks SU series single pass UV printers are equipped with a new UV print head authorized by Epson.

Sunthinks single pass UV printer uses a self-developed special motherboard, which perfectly matches the machine and has strong stability. The printer has also obtained a variety of utility model patent technology protection.

Sunthinks' original intelligent negative pressure ink supply system and ink circulation system ensure stable and smooth ink supply during printing. The advantages are more prominent when the printer works under long-term high load.

Support variable data (VDP) and multi-task continuous printing to meet customers' customized personalized printing needs. Different graphic prints can be printed continuously without pausing the printer, including personalized printing of text, numbers, pictures, barcodes, etc.

Sunthinks single pass UV printer supports CMYK 4-color printing, or CMYK+W 5-color printing, supports monochrome, multi-color, and gradient color printing, with an accuracy of up to 1200dpi.

The printer adopts direct-injection printing, which does not require plate making. It is flexible in application and can print as soon as it is turned on.

High-efficiency plasma treatment to enhance the adhesion of ink on the material surface.

Use environmentally friendly UV ink that has been deeply tested by the manufacturer. It not only has high color saturation, is waterproof, anti-oxidation, and wear-resistant, but can also significantly reduce the generation of VOCs waste gas.

The patented feeding belt has an automatic deviation correction function and cooperates with the suction function of the printing platform to ensure accurate printing position.

It is widely used in various industries and is not picky about materials. It is suitable for high-speed flat printing on all materials, including but not limited to metal, plastic, leather, coated paper, wood, glass and other materials.

Professional automatic feeder, efficient and fast feeding, saving manual feeding costs.

A wide range of models are available to support printing of various widths, meeting the printing size requirements of different industries and materials.

High production efficiency: The biggest advantage of Single Pass technology is the fast printing speed. Because the nozzle can complete color printing of the entire format by passing through the material at one time, there is no need to print back and forth multiple times like a flatbed UV printer, which greatly improves work efficiency and is especially suitable for large-scale, continuous production scenarios.

Reduced mechanical wear: Due to the reduced number of movements of machine parts, mechanical wear and maintenance frequency can theoretically be reduced.

Stability and consistency: High-end Single Pass UV printers are usually equipped with multi-channel precision inkjet systems, which can ensure image quality and color consistency during high-speed printing.

Quickly change printing materials: Single pass UV printers are equipped with a matching automatic paper feeder, while conventional flatbed UV printers require manual placement of printing materials in sequence.

Cost-effectiveness: Although the initial investment cost may be higher, its efficient production model reduces unit costs, and long-term operation can save a lot of time and energy costs, especially for large-volume orders, which has significant economic benefits.

Higher flexibility: Single Pass uv printers are more adaptable to small batches and customized needs, and can quickly switch to product printing of different sizes or materials.

Powerful functionality: Single pass printers are equipped with variable data printing and multi-task continuous and uninterrupted printing functions.

Reduced mechanical wear: Due to the reduced number of movements of machine parts, mechanical wear and maintenance frequency can theoretically be reduced.

Stability and consistency: High-end Single Pass UV printers are usually equipped with multi-channel precision inkjet systems, which can ensure image quality and color consistency during high-speed printing.

Quickly change printing materials: Single pass UV printers are equipped with a matching automatic paper feeder, while conventional flatbed UV printers require manual placement of printing materials in sequence.

The initial investment is relatively high: The technical complexity and manufacturing cost of Single Pass UV printers are relatively high, so the initial investment cost is higher than that of flatbed UV printers.

High maintenance requirements: Due to its complexity, once a failure occurs or maintenance is required, a professional technical team may be required to repair it, and the cost of replacing the expensive print head set may also be high.

Applicable materials are limited: Although suitable for a variety of materials, the Single Pass UV printer may not be as flexible as a flatbed printer for media that is not flat or cannot be laid flat, as it relies on the media to pass smoothly through the printing area in a single pass.

In summary, UV Single Pass printers are more suitable for large-scale industrial production and situations requiring extremely high printing speeds, while flatbed UV printers have higher flexibility and economy in handling small batches, diverse and more complex projects.

Why Choose US

Fast pace has become a development trend. Whether it is factory production speed, order delivery time or freight transportation time, they are all factors that influence customers to choose you.

Large-volume printing orders have become history, and multi-batch, small-volume printing orders have become the market norm.

Printing services are developed through multi-channel operation of physical stores and online stores. Timely services and customized diversity are essential.

The price of raw materials has risen, reducing printing production costs, simplifying the production process to form a stable supply chain, and creating high profits at low costs.

Personalization and customization: Customers may require the rapid completion of small batches, multiple varieties, and personalized printed materials with variable data information, such as labels, business cards, brochures, etc. UV digital printing technology is well suited to meet such needs due to its flexibility and instant curing properties.

Quality Requirements: Customers usually expect UV printing to provide high-definition, bright colors, rich details and strong durability, especially for color accuracy, saturation and fine line expression. For packaging products, it may also need to have good wear resistance, scratch resistance, UV aging resistance and other properties.

Environmental requirements: With the increasing awareness of environmental protection, more and more customers require the use of low-VOC (volatile organic compounds) or solvent-free UV inks for printing to reduce environmental pollution and ensure that products comply with relevant regulations and green standards.

Delivery Time: In a fast-paced business environment, customers often need to obtain high-quality printing products in a short period of time. Therefore, UV printing companies need to have quick response capabilities and efficient production processes to shorten the delivery cycle.

Material adaptability: Customers hope that UV printing can be applied to various types of materials, including hard surfaces such as metal sheets (printing before stamping of metal products such as cola cans, tea cans, milk powder cans, etc.), glass plates, plastics, tiles, etc., as well as soft materials such as leather, coated paper, etc.

Cost control: Although UV printing technology brings many advantages, cost is still a focus of customers. They expect to receive reasonable prices and service plans while ensuring printing quality.

Technical certification and compliance: Especially in areas such as food packaging and children's toys, customers will require UV printing to comply with food safety regulations and other industry-specific safety standards.

To sum up, UV printing service providers need to continuously improve their processes, improve equipment efficiency, select high-quality consumables, and flexibly adjust their business models to meet the diverse needs of customers.

Solve low production efficiency: Traditional flatbed UV printers require the print head to move back and forth multiple times to complete the printing of an image, while Single Pass UV printers only need one time to complete printing, significantly improving production speed, greatly increasing production capacity, and effectively solving the problem of low production efficiency.

Reduce production costs: Due to its high-speed continuous production characteristics, more products can be produced per unit time, thereby diluting fixed costs and reducing the production cost of each product, allowing enterprises to be more competitive in a highly competitive market environment. Advantage.

Meet personalized customization needs: Although it is known for its high efficiency, the high-end Single Pass UV printer also supports variable data printing (Variable Data Printing), which can achieve fast and accurate one-to-one product customization services.

Reduce downtime and maintenance time: Compared with the traditional multi-pass printing method, the Single Pass print head wear is relatively uniform and there is little mechanical loss caused by repeated movement. In theory, it can reduce the need and frequency of equipment repair and maintenance.

Improve product quality consistency: Using a sophisticated printing system and advanced ink droplet control technology, the consistency and accuracy of output quality can be ensured even under high-speed printing, helping to improve the overall product quality.

Adaptable to industrial mass production: It is suitable for various industrial-level mass production scenarios, especially suitable for large-area continuous pattern printing of hard materials such as aluminum plates, ceramic tiles, and wooden boards, solving the pain point of traditional equipment being difficult to efficiently handle such large-volume tasks.

Factory History: 21-year-old printer factory, completely independent research and development, no competitors in the same quality, price, and printing size.

R&D experience: Sunthinks Single Pass digital printing project started in 2018. It is the earliest manufacturer in China to carry out technology research and development. It has industry-leading technology foundation and product experience, and is protected by numerous patents.

Customer endorsement: Sunthinks is the top in China's digital Single Pass packaging printing equipment industry. So far, we have sold more than 1,500 single-pass printers worldwide, with the highest domestic market share and the highest overseas sales. We also have many domestic and foreign agents and customers endorsing us.

Approved by big manufacturers: Sunthinks is the first brand in China to sign cooperation agreements with major manufacturers such as Epson and HP. The print heads used are all from the original manufacturers of the brands, and are guaranteed to be brand new and genuine. We refuse to use second-hand disassembled heads bought on the market, and refuse to pass off inferior products as good ones.

Customer first: We conduct quality inspection at every level from raw materials to finished products, with the aim of reducing customers' troubles, improving their experience and helping our customers and agents make money.

Company Profile

Contact Us

Contact : Sophia Song

Tel : +0086-755-26975191

Tel : +0086-755-26975191

Mob : (+86)-189-3886 8710 (WhatsApp)

Wechat : yuxunda10

Skype : Sophia_yxd

QQ : 1994228467

E-mail : info@yuxunda.com

Website : www.yuxunda.com

Add : Floor 1-4, A5 Building,Niujiaolong Industrial Park, Zhangkengjing, Guanlan, Longhua District, Shenzhen, Guang- dong, China

Wechat : yuxunda10

Skype : Sophia_yxd

QQ : 1994228467

E-mail : info@yuxunda.com

Website : www.yuxunda.com

Add : Floor 1-4, A5 Building,Niujiaolong Industrial Park, Zhangkengjing, Guanlan, Longhua District, Shenzhen, Guang- dong, China

We Recommend

New Arrivals

New products from manufacturers at wholesale prices