Automatic Beef Jerky Chicken Roast Pork Marinating Vacuum Tumbler Machine

- Category: >>>

- Supplier: Zhucheng Shuke Machinery Technology Co. Ltd.Zhucheng Ltd.

Share on (1601326222414):

Product Overview

Description

Products Description

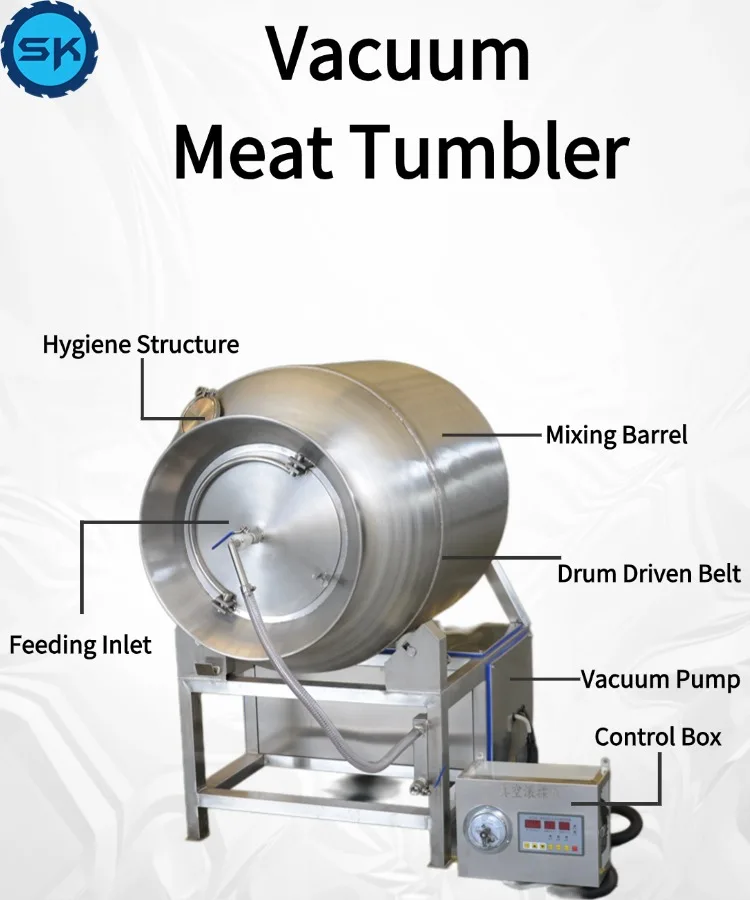

SHUKE Vacuum Tumbler Machine

There are two types of rolling kneading machine produced by our company, hydraulic vacuum rolling kneading machine and vacuum rolling kneading machine. Hydraulic roll kneading machine adopts rotating support, horizontal hydraulic tilt roll kneading.Compared with the ordinary rolling and kneading machine series, it has greater loading capacity and more convenient discharge performance. The roller kneading machine can improve the tissue structure of meat, improve the water retention of meat, there by improving the elasticity and yield of the product and reducing the loss of raw materials.

Function configuration:

1.With continuous vacuum function. Two kinds of rolling methods can be selected: vacuum rolling (fixed vacuum degree) and respiratory rolling (vacuum atmospheric pressure alternating change). The respiratory rolling function can effectively shorten the rolling time and improve the rolling efficiency. The vacuum meter displays the vacuum degree in the barrel in real time, and grasps the vacuum condition at any time.

2.High standard of health design. The machine is made of high quality SUS304 stainless steel material, the bracket is made of stainless steel square pipe, the interior and surface of the roller are finely polished and polished, there is no sanitary dead Angle, and the discharge position can be thoroughly drained; And reduce additional temperature rise.

3.Variable frequency stepless speed regulation. Start smoothly, reduce the impact when the machine starts, extend the service life of the equipment; Save energy consumption; The speed is adjustable.

4.Can use touch screen control, more intuitive operation, with good waterproof and moisture-proof performance. 5.According to the different needs of a variety of products, you can choose "single" or "V" blade.

6.According to product characteristics. Can choose human tooling material, mechanical loading material or vacuum suction material, vacuum suction port.

Product Display

Product Paramenters

Model NO | Volume (L) | Refer to feed (KG) | Power (KW) | Host size (MM) | Weight (KG) |

SGR-50 | 50 | 30 | 1.1 | 850*510*940 | 100 |

SGR-100 | 100 | 50 | 1.5 | 1020*610*1050 | 130 |

SGR-200 | 200 | 100 | 1.5 | 1120*720*1210 | 150 |

SGR-300 | 300 | 150 | 2.25 | 1300*820*1320 | 210 |

SGR-400 | 400 | 200 | 2.25 | 1400*920*1400 | 260 |

SGR-500 | 500 | 250 | 2.4 | 1450*1020*1560 | 280 |

SGR-600 | 600 | 300 | 2.4 | 1600*1020*1560 | 300 |

SGR-800 | 800 | 400 | 4.55 | 1800*1020*1560 | 320 |

SGR-1000 | 1000 | 500 | 5.35 | 2000*1120*1660 | 350 |

SGR-1200 | 1200 | 600 | 6.85 | 2030*1230*1820 | 460 |

SGR-1500 | 1500 | 800 | 9.85 | 2230*1230*1820 | 490 |

SGR-1800 | 1800 | 900 | 7.55 | 2500*1230*1820 | 520 |

SGR-2000 | 2000 | 1000 | 7.55 | 2510*1330*1920 | 690 |

SGR-2400 | 2400 | 1200 | 9.5 | 3400*1430*1830 | 800 |

SGR-2700 | 2700 | 1400 | 11.5 | 3500*1530*1920 | 1000 |

SGR-3000 | 3000 | 1500 | 11.5 | 3600*1640*1980 | 1500 |

SYGR-750 | 750 | 340 | 5.25 | 2800*1700*1800 | 1000 |

SYGR-1700 | 1700 | 900 | 9 | 3200*1800*2000 | 1500 |

SYGR-2500 | 2500 | 1300 | 13 | 3500*2200*2200 | 2000 |

Details Images

PLC Control Design

Widen Roll Belt

Widen roll blet extremely increase bearing lower wearing,matched with dual hydraulic support for reliable performance after crutial long time running.

Widen Bearing Wheel

The widen bearing wheels ensure reliable

bearing capacity without need of replacement

of wheels in the future.

Fully Automatic Vacuum

Machine Applications

About our company

Product packaging

Why Choose Us

Many years of industry experience

The company has many years of industry experience, strong economic strength, independent production capacity, fast delivery, good corporate reputation, perfect management system and after-sales service.

Integrated operation enterprise

It is a modern food machinery production enterprise that integrates research and development, manufacturing, production, sales,and service. The company's products have excellent performance, quality assurance, reliability and durable.

Continuously learning

The company adheres to the development path of "people-oriented, daring to innovate", constantly absorbs advanced technology and

processes, innovates and develops, and sincerely looks forward to honest cooperation with customersCreate brilliance together.

processes, innovates and develops, and sincerely looks forward to honest cooperation with customersCreate brilliance together.

Thoughtful after-sales service

Provide regular free maintenance services for the provided equipment, provide job training for the demand side operators, conduct

regular follow-up visits to customers, provide attentive after-sales service, and wholeheartedly provide satisfactory product

services to our customers.

regular follow-up visits to customers, provide attentive after-sales service, and wholeheartedly provide satisfactory product

services to our customers.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices