Tungsten Tin Tantalum Niobium Ore Processing Equipment Mining Plant

- Category: >>>

- Supplier: Henan Zoomjo International Trade Co. Ltd.Henan Ltd.

Share on (1601331775963):

Product Overview

Description

Tungsten Tin Tantalum Niobium Ore Processing Equipment Mining Plant

Product Description

—Tungsten Processing Plant—

Tungsten Ore Processing Plant In Uganda

5TPH Rock Tungsten Processing Plant in Zambia

Tungsten Ore Processing Plant In Uganda

5TPH Rock Tungsten Processing Plant in Zambia

The wolframite ore has a high depletion rate, low grade, coarse grain size, high density, low hardness, easy mud formation and deep color, which is mainly extracted by the gravity separation process. China’s wolframite ore beneficiation production has a history of more than 60 years and has accumulated rich experience, which can be summarized as the following parts.

1. Pre-enrichment, early throwing the waste rock, then washing, desliming, grading, crushing.

The dilution ratio of wolframite mining is generally around 80%. The amount of surrounding rock in the ore is large, and are easy to distinguish with wolframite containing rock. Pre-select the waste rock increases the beneficiation processing capacity and efficiency, and reduces the rock crusher wear.

2. Gravity separation, grading and sorting. Jig concentrator – shaker table to recover the coarse particle wolframite.

3. Fine wolframite slime concentration

Fine wolframite slime includes primary and secondary slime, which accounts for about 10% of the original ore. The tungsten grade is higher than the original ore, grade is 14% to 15%. Extract tungsten from slime is an important method for improving the tungsten recovery rate. Wolframite slime concentration machines have shaker tables, centrifugal concentrators, belt chute, flotation, magnetic separation. The fine mud recovery rate has increased from 10% ~ 50% to 60%~70%.

Get Small Tungsten Processing Plant Equipment Factory Price List Online

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia,Tanzania, Peru, Mexico.

Just leave us your whatsapp or email, we send the latest price list to you.

Whenever, 7X24 hours online service is waiting for you.

Hot-sale in many countries: Zimbabwe, Mozambique, Zambia, South Africa, Kenya, Philippines, Indonesia, Vietnam, Uganda, Ethiopia,Tanzania, Peru, Mexico.

Working Flow

Tungsten Extraction Process:

Roughing

In the first stage of fine-grained roughing, Zoomjo group adopts jig to separate, then directly enters into the concentrating stage.

Gravity separation

Zoomjo group adopts multi-stage jigging, multi-stage shaking table, middling regrinding and gravity separation process.

That is, the jigging gross sand is produced when the qualified ore is sent to multi-stage jigging after the vibrating screen. The coarse-grained jig tailings are sent to grinding mill for re-grinding, and the fine-grained jig tailings enter into multi-stage shaking table after the classifier, then the shaking table gross sand is produced. The shaking table tailings are sent to the tailings pond, and the middlings are returned for regrinding and re-separating, and the gross sand of jig and shaking table is sent to concentrating stage.

Concentrating:

Zoomjo group adopts flotation-gravity separation combined process or flotation-gravity separation-magnetic separation combined process, and recovers the associated elements in the concentrating stage.

Through the coarse and fine-grained table flotation (flotation -shaking table combined method) and flotation to remove the sulphide ore, the sulphide ore of table flotation and flotation merges into the sulfide ore flotation separation. And the wolframite after table flotation and flotation becomes the wolframite concentrate by the gravity separation process. If there are scheelite and cassiterite in the wolframite concentrate, gravity separation-flotation or gravity separation-flotation-magnetic separation combined process can be adopted to separate wolframite concentrate, scheelite concentrate and tin concentrate.

Through the coarse and fine-grained table flotation (flotation -shaking table combined method) and flotation to remove the sulphide ore, the sulphide ore of table flotation and flotation merges into the sulfide ore flotation separation. And the wolframite after table flotation and flotation becomes the wolframite concentrate by the gravity separation process. If there are scheelite and cassiterite in the wolframite concentrate, gravity separation-flotation or gravity separation-flotation-magnetic separation combined process can be adopted to separate wolframite concentrate, scheelite concentrate and tin concentrate.

Complete Mining Plants for Different Minerals Separation | ||||

Coltan | Diamond | Zircon sand | ||

Tantalum | River sand gold | Titanium | ||

Cobalt | Alluvial gold | Tin /Cassiterite | ||

Tungsten | Rock stone gold | Heavy minerals sand | ||

Tantalite | placer gold | Chromium ore | ||

Silica sand | Gold tailing | Monazite | ||

Copper | Clay gold mining | Tungsten ore | ||

Barite | Desert sand gold | llmenite | ||

Chrome | Quartz | Wolfram ore | ||

Iron ore | Coal | Niobium | ||

Manganese ore | Sand gravel | Rutile | ||

Fluorite | Topsoil | Hematite | ||

Product Details

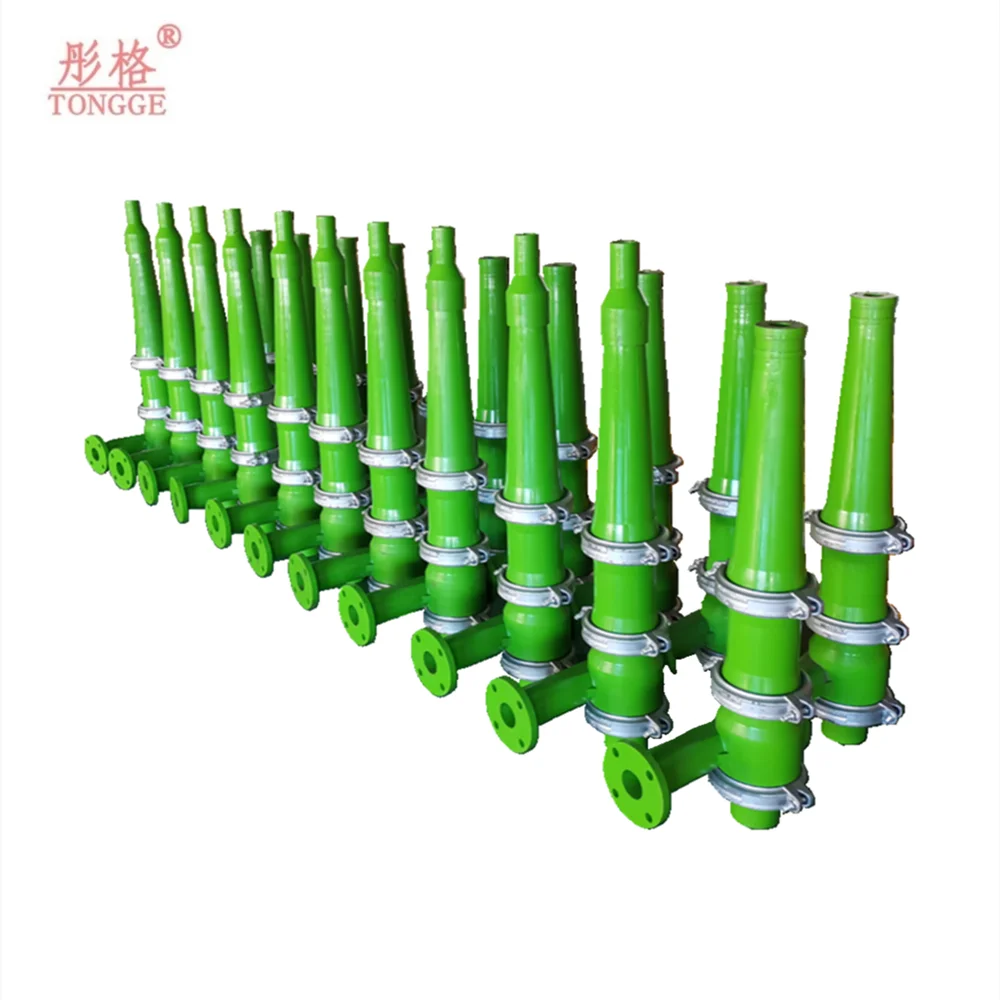

Tungsten mining process equipment

1) 1 set jaw crusher: for crushing big size stone into a small stone

2) 1 set ball mill: Grinding small stone to fine material minus 1 mm

3) Spiral chute: Rough concentrate heavy minerals after ball mill

4) gold shaking table: the concentrate ore from spiral chute will go to shaking table for separation

5) flotation cell: Use flotation to remove arsenic

2) 1 set ball mill: Grinding small stone to fine material minus 1 mm

3) Spiral chute: Rough concentrate heavy minerals after ball mill

4) gold shaking table: the concentrate ore from spiral chute will go to shaking table for separation

5) flotation cell: Use flotation to remove arsenic

Our Advantages

Our senior technical engineers can provide solutions to the problems you encounter through online or quickly arrive at your production site at any time, and our experienced installation team can quickly and efficiently build and install your cement line factory, allowing you Produce cement products that meet the requirements in the shortest time, allowing you to see benefits in the shortest time.

Customer Cases

Packaging Details: We will make different packaging according to different machine sizes. Standard international export packing, container, wooden box.

Delivery Time: We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Company Profile

ZOOMJO is a large-scale enterprise that mainly produces heavy mining machinery and integrates scientific research, production and sales. It mainly produces various large and medium-sized crushing equipment, sand making equipment, drying and calcining equipment, mineral processing equipment and other series of products.

ZOOMJO has developed steadily from its establishment to the present with its technical strength, and has grown stronger day by day, and has gathered a large number of high-level management and scientific research personnel. Our company covers an area of 50,000 square meters, and another 10,000 square meters of modern office space, R&D center and sales center. The company has more than 500 employees, including more than 20 intermediate technicians. With strong technical strength, scientific management system and high product quality, ZOOMJO will rapidly grow into an important production and export base of mining machinery.

FAQ

1. How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2. Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

3. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food.

4. Service and Payment Terms?

a. We usually accept T/T, L/C, but other terms also workable.

b. We take pictures of finished products before delivery.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices