Made in China Biscuit and Cookies Making Machine fully automatic lines equipment for biscuits making and packing

- Category: >>>

- Supplier: Jinan Xilang Machinery Co. Ltd.Jinan Ltd.

Share on (1601331831732):

Product Overview

Description

Hard Soft Biscuit Line Small Mini Biscuit Cookies Making Machine For Restaurants Biscuit Making Machine Fully Automatic

PRODUCTS DESCRIPTION

Brief introduction of biscuit machine small biscuit making machine automatic biscuit production line

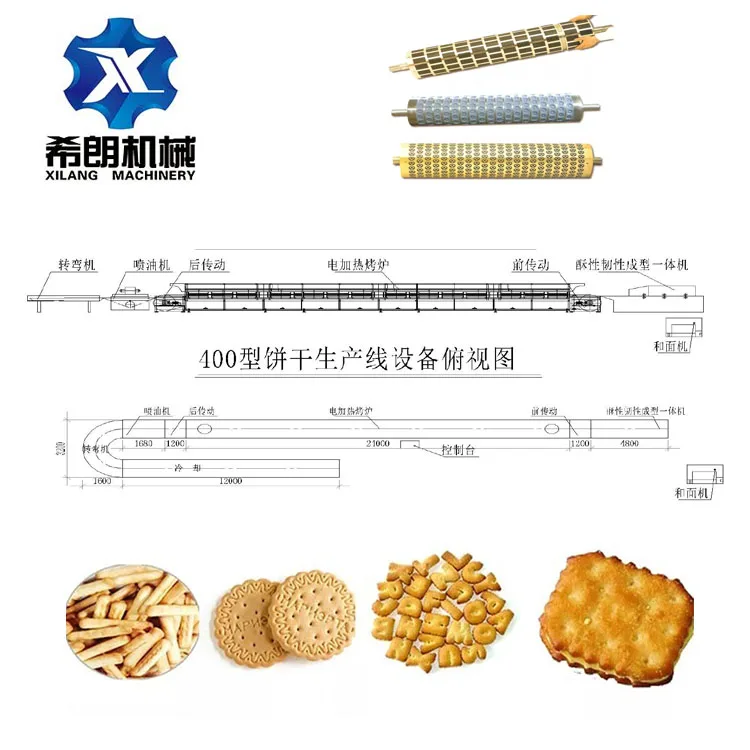

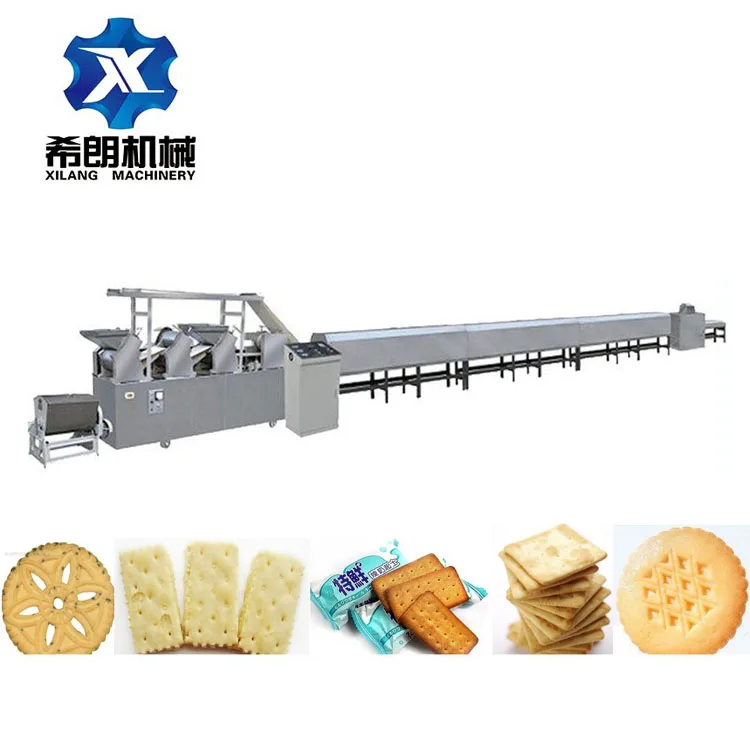

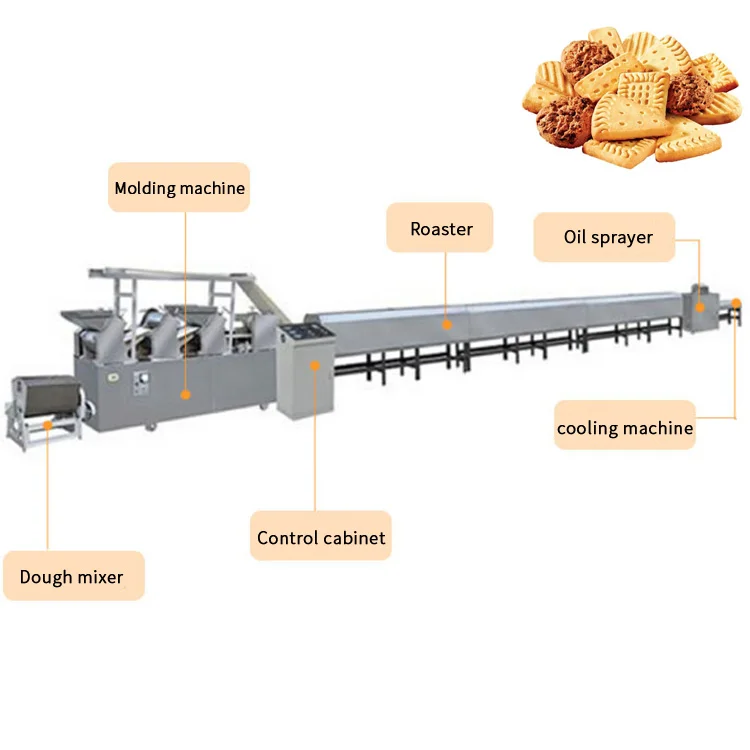

Xilang biscuits production line consists by the biscuit forming machine, tunnel type electrical hot air circulating oven, turning machine, cooling line, biscuits sorting machine, biscuit sandwich/injesting machine, packing machine etc. From feed to three pressing of surface forming, sifting sugar, transportting, waste recycling, baking, cooling all completed automatically.

Raw materials of biscuit machine small biscuit making machine automatic biscuit production line

adopts wheat flour as the main raw material, add salt, sugar, oil, eggs, dairy products and other auxiliary materials

Products of biscuit machine small biscuit making machine automatic biscuit production line

The production line has the function of roll cutting and roll printing, so it can produce both tough biscuits and crisp biscuits.There are more than 1000 kinds of mold patterns.

PRODUCT SPECIFICATIONS

Model No. | Production capacity | Width of conveying belt | Power rate for tunnel oven | Voltage |

XL-250 | 50-100kg/h | 250mm | 4.5kw/m | 380V,50Hz |

XL-400 | 100-200kg/h | 400mm | 6.75kw/m | 380V,50Hz |

PRODUCT CONFIGURATION

The Process flow of biscuit machine small biscuit making machine automatic biscuit production line

mixing — forming — drying — Oil spraying — Cooling line — stacking— injecting — Biscuit packing

machine

machine

The equipments list of biscuit machine small biscuit making machine automatic biscuit production line

1. Flour mixer — 2. Roll cut biscuit forming machine / Roll print biscuit forming machine — 3.Tunnel oven — 4.180degree Turning machine — 5.Oil spraying machine — 6.Cooling line — 7.Biscuit stacking machine — 8.Biscuit sandwich machine — 9.Biscuit packing machine

MAIN MACHINE DETAILS

Flour mixer

Function:

This machine is used in dough mixing.

After mixing, the dough surface will be good elasticity and smoothness. It's suitable for hard biscuit and soft biscuit.

Type:

Vertical and Horizontal dough mixer

Feature:

It's independently used with other machines.

It's independently used with other machines.

Rotary cutter for hard biscuit

When the mixed dough sheet go through the rotary cutter machine,it will be cut and shaped.And the scrap will be conveyed to the hopper by recycle device.Then biscuit dough pieces will separated go to next step.

Roll print for hard biscuit

There is a hopper above the roller.the dough will go thought the rotary molder,the biscuit formed and then go to next process.

Tunnel oven

Function:

Bake the biscuit pieces long time under low temperature in order to make biscuit ripe.

Types:

Gas oven,Electrical oven and Hot air circulation oven.

Gas oven,Electrical oven and Hot air circulation oven.

Oil sprayer

Function:

Cover the baked biscuits with one level oil,ensure the biscuit more delicious and more beautiful.

This machine can improve grades and colors of biscuit.

Cooling machine

Function:

It's used to cool and deliver the biscuits before packing.

This machine can ensure the quality of the biscuits after packaging and to extend the shelf life.

Biscuit Stacking Machine

Function:

This machine forms the biscuits on cooling conveyor into lanes, stacks them on edge through the star wheel device, and conveys them to the packing conveyor. Inject / Sandwich machine (Optional)

Function:

This machine is used to make sandwich biscuit.

This machine is used to make sandwich biscuit.

SAMPLE PHOTOS

PACKING AND SHIPPING

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

2).Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country); by ship-please tell me your delivery port.

2).Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country); by ship-please tell me your delivery port.

COMPANY PROFILE

FAQ

Q1: Are you a trade company or a manufacturer?

A1:We are a manufacturer,we have own factory and R&D department.

SGS has certified our company on site.welcome to visit our factory and check the machines.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss

before contract.

Q3: Could you supply all the parameters about the machines?

A3: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q4. Can you provide food or feed formula?

A4: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q5: What is your terms of payment ?

A5: 30% T/T in advance ,70% balance before shippment after inspection.

Q6: How about the after-service?

A6: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

A1:We are a manufacturer,we have own factory and R&D department.

SGS has certified our company on site.welcome to visit our factory and check the machines.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss

before contract.

Q3: Could you supply all the parameters about the machines?

A3: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q4. Can you provide food or feed formula?

A4: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q5: What is your terms of payment ?

A5: 30% T/T in advance ,70% balance before shippment after inspection.

Q6: How about the after-service?

A6: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices