Enneng permanent magnet synchronous electric stator linear motor manufacturers factory

- Category: >>>

- Supplier: Qingdao Enneng Motor Co. Ltd.Qingdao Ltd.

Share on (1601341192223):

Product Overview

Description

Permanent Magnet Motor

Adopting high efficiency NdFeB permanent magnet, no excitation loss, after special rotor structure design, greatly reduces iron loss and stray loss, the efficiency of the whole machine reaches lE4 standard or more, 5-10% higher than the efficiency of three-phase asynchronous motor, power factor increased by10-15% or more.

Energy efficiency standards | Comply with IE4, IE5 grade | Work mode | S1~S10 |

Installation dimensions | Comply with IEC standard | Control mode | variable frequency vector control |

Power range | 5.5〜6300kW | Installation type | IMB3 IMB5 IMB35 V1 |

Cooling way | IC411 or IC416, IC410, IC71W, IC81W | Rated speed | 150~3600RPM |

Insulation class | F(H) | Optional parts | Encoder, spiral transformer, PTC, PT100 |

Protection grade | IP55(IP23 start type is customizabe) | Wiring type | junction box (aviation plug can be customized as per requirement) |

Connection | STAR, DELTA | Rated voltage | 380V 660V 1140V 3300V 6KV 10KV |

Product Catagory

All You Need To Know About PMSM Motor

The structure of the permanent magnet synchronous motor

Classification

Depending on how magnets are attached to the rotor and the design of the rotor, permanent magnet synchronous motor can be classified into two types: Surface permanent magnet synchronous motor(SPMSM)

Interior permanent magnet synchronous motor (lPMSM).SPMSM mounts all magnet pieces on the surface, and IPMSM places magnets inside the rotor

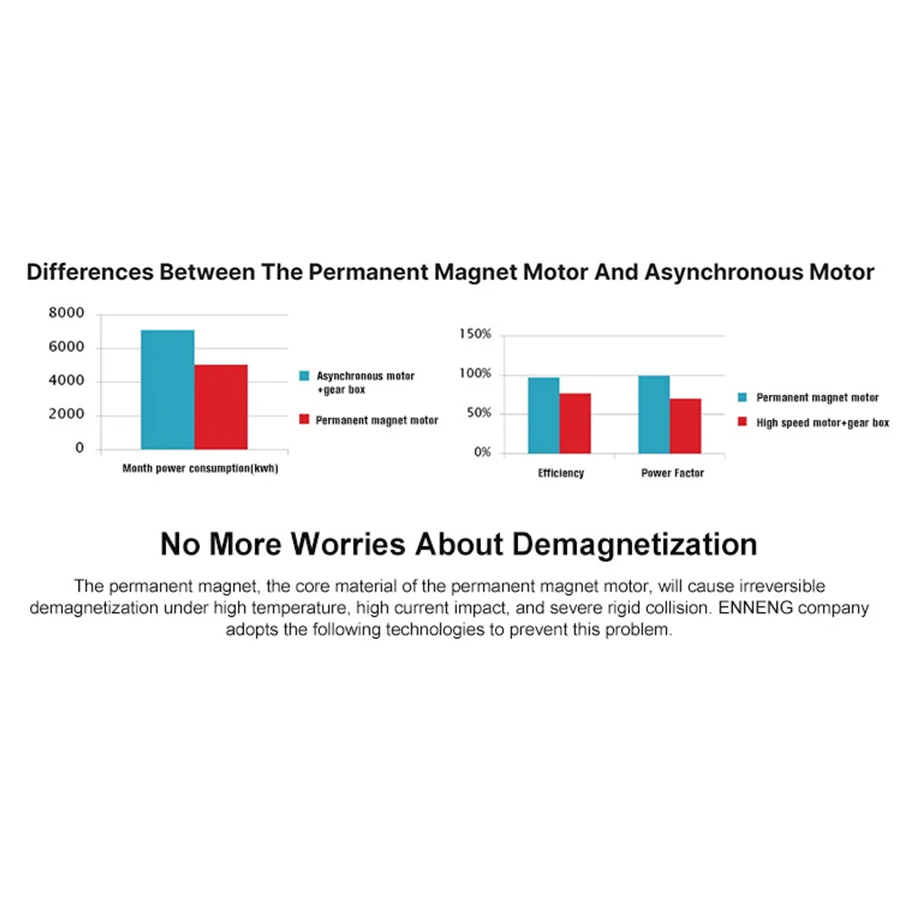

Differences Between The Permanent Magnet Motor And Asynchronous Motor

No More Worries About Demagnetization

The pemanent magnet, the core material of the permanent magnet motor, will cause irreversible demagnetization under high temperature, high current impact, and severe rigid colision. ENNENG company adopts the following technologies to prevent this problem.

Prevention Program | Prevent high temperature demagnetization | Prevent high current impact demagnetization | Prevent violent rigid collision demagnetization |

Measure 1 | Select permanent magnet material N38SH/N38UH resistant to above 150℃ | Built-in placement of magnets | Built-in placement of magnets |

Measure 2 | Carry out the internal thermal simulation of the motor to ensure that the thermal concentration of the motor does not exceed the motor material temperature resistance | Check the maximum demagnetization operating point when the motor is short-circuited, so that there is no irreversible demagnetization when the motor is short-circuited. | The rotor magnetic pole is made of soft silicon steel sheet |

Comparison of Motor Efficiency

Standard type motor efficiency is equivalent to lE3 (high effciency:>GB2 grade) General type motor efficiency is above lE4 (ultra high efficiency:>GB1 grade)

Product application

Permanent Magnet Generator

1) Low-speed direct drive, eliminating the speed increaser, the wind blade or hydro turbine can be directly connected with the generator, coaxial rotation, simplifying the structure and improving the system performance. The generator can directly output 50HZ at low speed.

2) Permanent magnet generator in the whole speed range of the motor is efficient operation, high power generation efficiency, the motor heat is small, can rely on natural conditions heat dissipation.

3) High efficiency, small starting torque, can achieve low-speed power generation. The system runs smoothly and the performance is stable. The motor runs at low speed, the power generation is stable, and the service time is doubled.

4) Can change the voltage, speed, power and other parameters according to needs, can change the appearance, can use spline shaft extension, double shaft extension, front end stop output, etc.

2) Permanent magnet generator in the whole speed range of the motor is efficient operation, high power generation efficiency, the motor heat is small, can rely on natural conditions heat dissipation.

3) High efficiency, small starting torque, can achieve low-speed power generation. The system runs smoothly and the performance is stable. The motor runs at low speed, the power generation is stable, and the service time is doubled.

4) Can change the voltage, speed, power and other parameters according to needs, can change the appearance, can use spline shaft extension, double shaft extension, front end stop output, etc.

Packaging and transportation

Company Profile

Qingdao Enneng Motor Co., Ltd. (abbreviated as “ENNENG”) is a high-tech enterprise integrating R & D and manufacturing of permanent magnet motors and permanent magnet generators. With more than dozens of patents, Enneng has ranked as “100 Innovative Enterprises” in Qingdao and we have been selected as a member of the Qingdao Motor Association.

Product mainly include energy saving permanent magnet motor, and permanent magnet generator used for renewable energy.

Enneng low speed high torque permanent magnet synchronous motor with its mature products, good performance and obvious energy-saving effect, has been widely used in China's large enterprises, and exported to Europe, North America, South America, Southeast Asia, South Asia, Africa and other regions.

Product mainly include energy saving permanent magnet motor, and permanent magnet generator used for renewable energy.

Enneng low speed high torque permanent magnet synchronous motor with its mature products, good performance and obvious energy-saving effect, has been widely used in China's large enterprises, and exported to Europe, North America, South America, Southeast Asia, South Asia, Africa and other regions.

FAQ

1. Q: How does your permanent magnet generator work?

A: Our generator needs to be driven by other energy, like wind power, water power, belt, etc, then it can generate electric power.

2. Q: What is the power of your generator?

A: We can manufacture from 5.5kw to 6000kw.

3. Q: Can you manufacture customized product?

A: Yes, we can.Please tell your detailed request (power, speed, voltage and frequency) to our sales, we will make the generator according to your request.

4. Q: Can your company provide OEM service?

A: Yes, we can.

A: Our generator needs to be driven by other energy, like wind power, water power, belt, etc, then it can generate electric power.

2. Q: What is the power of your generator?

A: We can manufacture from 5.5kw to 6000kw.

3. Q: Can you manufacture customized product?

A: Yes, we can.Please tell your detailed request (power, speed, voltage and frequency) to our sales, we will make the generator according to your request.

4. Q: Can your company provide OEM service?

A: Yes, we can.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices