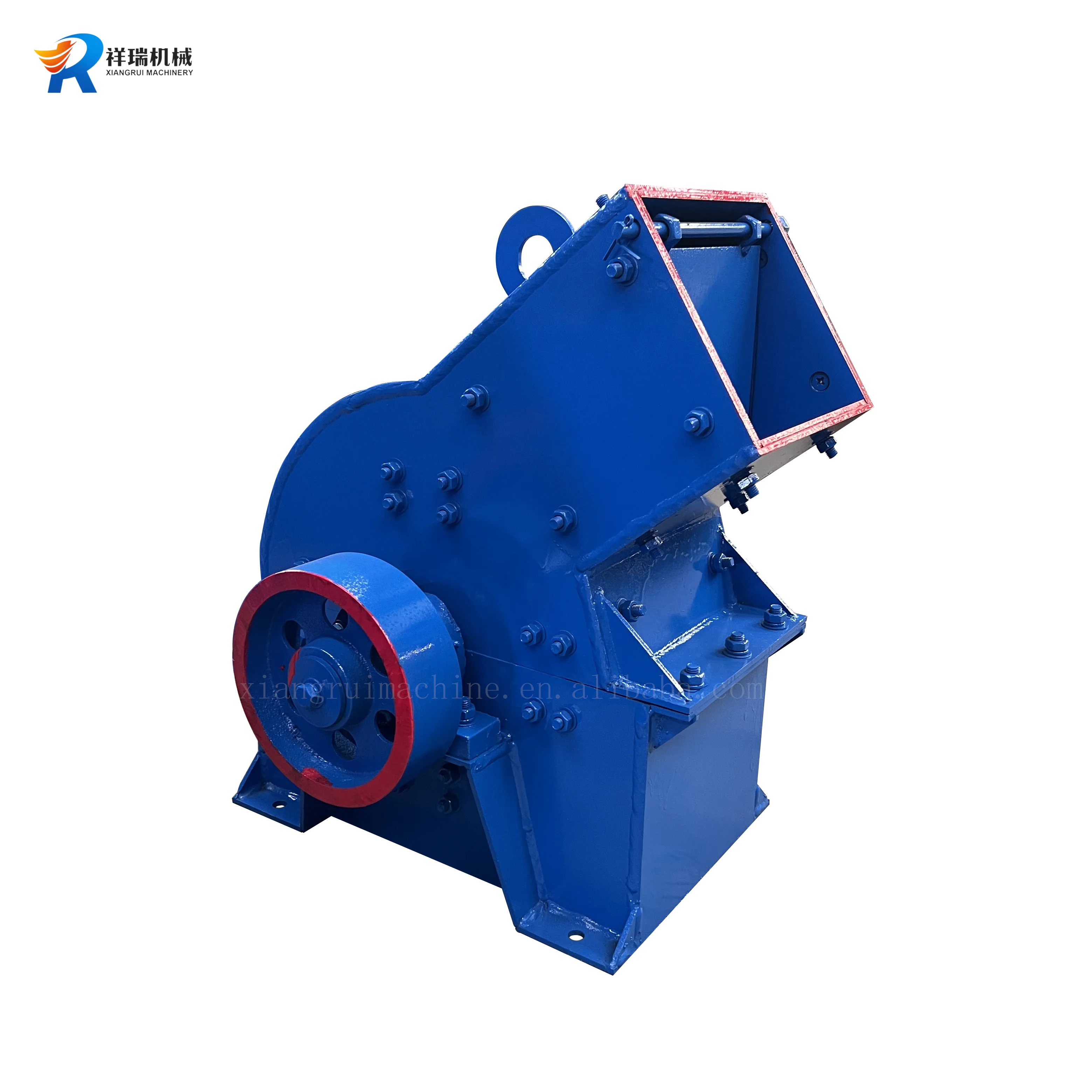

Stone crusher manufacturers use small hammer crushers for crushing limestone iron ore

- Category: >>>

- Supplier: Gongyi City Xiangrui Machinery Manufacturing Co. Ltd.Gongyi Ltd.

Share on (1601341830259):

Product Overview

Description

We are a real source factory, we will guarantee to have a video conference with you at any time, and on the premise of ensuring product quality, let you buy with confidence, use more assured.

We revolve around finding reputable overseas distributors, cultivating strong international relationships, and providing exceptional product after-sales support. Doing a good job in product after-sales service is our aim to achieve a mutually beneficial cooperation vision. We eagerly look forward to a fruitful and pleasant partnership with you.

We revolve around finding reputable overseas distributors, cultivating strong international relationships, and providing exceptional product after-sales support. Doing a good job in product after-sales service is our aim to achieve a mutually beneficial cooperation vision. We eagerly look forward to a fruitful and pleasant partnership with you.

Products Description

Hammer Crusher

Hammer crusher is also known as stone crusher and hammer sand making machine. Cracking of the material is mainly due to the force of the impact. The material enters the hammer crusher through the feeding device, and the high-speed rotating hammer head and the collision surface of the falling material crushes the material. It is widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries.

It can be equipped with either a diesel engine or an electric motor. Customers can choose according to their needs. Hammer crusher is used for crushing all kinds of medium crushing and fine crushing medium hardness abrasive materials, the maximum compressive strength of the crushed materials is 150Mpa. water content is less than 15%. It is commonly used to crush limestone, coal, salt, gypsum, brick, limestone, brittle rock, alum and other hard materials; it can also crush lapis lazuli, cobblestone, granite, shale, slag, lignite and other hard materials. Hammer crusher mainly relies on impact energy to complete the operation of crushing materials. When working, the motor drives the rotor to rotate at a high speed, and the materials enter into the crusher cavity evenly, the high-speed rotating hammer head impacts, shears and tears the materials, so that the materials are crushed, and at the same time, the gravity of the materials themselves makes the materials rush to the baffle plate and sieve bar on the frame from the high-speed rotating hammer head, and the materials with a particle size larger than the sieve holes are blocked in the sieve plate to continue to be struck by the hammer head and grinding until they are crushed to the required particle size, and then pass through the sieve, and then the materials are crushed into the required particle size, and then pass through the screen. The material will be blocked on the screen plate and continue to be hit and ground by the hammer head until it is crushed to the required size, and then discharged to the outer disk of the machine through the sieve hole.

Product Paramenters

Model | Power | Size | weight | Capacity |

PC 240*450 | 7.5KW | 1200*900*1300mm | 0.35T | 4-7t/h |

PC 310*520 | 15KW | 1400*1000*1500mm | 0.5T | 8-10t/h |

PC 400*600 | 22KW | 1700*1050*1600mm | 0.65T | 15t/h |

PC 600*600 | 30KW | 2000*1200*1700mm | 1T | 25t/h |

PC 600*800 | 55KW | 1400*1100*1430mm | 1.2T | 30t/h |

PC 800*800 | 75KW | 1400*1100*1430mm | 2.6T | 35t/h |

PC 800*1000 | 90KW | 1600*1400*1650mm | 3T | 55t/h |

PC 1000*1000 | 110KW | 1600*1400*1650mm | 3.5T | 70 t/h |

How it works

1.Upper Body 2.Grate Plate

3.Middle Dody 4.Discharging Mouth

5.Hammer 6.Side Plate

7.Lower Body 8.Stand

9.Motor 10.Transmission Axle

11. Hammer Axle 12.Liner at Feeding Mouth

13.Liner

Hammer crusher working principle:

The hammer crusher mainly relies on impact to crush materials. The crushing process is roughly like this, the material enters the crusher, is subjected to the impact of the high-speed rotary hammer and is crushed, the crushed material, obtains kinetic energy from the hammer, rushes to the baffle in the frame from the high speed, the sieve bar, at the same time, the material hits each other, is broken many times, the material smaller than the gap of the sieve strip is discharged from the gap, and the individual larger materials are crushed by the impact of the hammer head on the sieve again, grinding, extruded and crushed, and the material is extruded from the gap by the hammer head. So as to obtain the product of the desired particle size.

Structural features:

The single rotor hammer crusher is mainly composed of a box, a turntable, a shaft, a hammer head, a grate, an adjustment frame and a coupling. The shell of the machine is a box-shaped structure welded with steel plates, and is divided into upper and lower two parts along the center of the axis, which are connected by bolts, and there is a feeding port above the casing. In order to avoid the wear and deformation of the inner wall of the box under the impact of the material, the inside of the casing is inlaid with a protective lining. There are two kinds of turntable triangle and circle, the three edges and corners of the triangle turntable are very easy to wear, if you find that it is not timely, it is easy to drop the hammer, and its service life is not as good as the round turntable. There are several mandrels, and the hammer head is staggered on the turntable respectively by the mandrel, and there is an isolation sleeve isolation between each hammer head. When the rotor rotates at high speed, the hammer crushes the material under centrifugal force.

Performance characteristics

The crushing ratio is large, the production efficiency is high, the crushed product is cubic, the flake content is low, there are no internal cracks, and the compressive strength is high. The overall design is beautiful and compact, with few wearing parts and easy maintenance.

As the source factory, we are trustworthy,You are welcome to contact us!

Product packaging and delivery

Shipping

We usually use wooden case packaging, if you have special needs, you can negotiate with us for customization, we can provide a variety of packaging solutions to meet the needs of sea or land transportation. Stable seismic resistance and customized protection ensure that each piece of equipment arrives safely in your country without worry.

Company Profile

Gongyi Xiangrui Machinery Manufacturing Co., Ltd.

Gongyi Xiangrui Machinery Manufacturing Co., Ltd. is a large-scale manufacturing enterprise mainly engaged in the production of brick making machine machinery and heavy mining machinery, integrating scientific research, production, sales and service. The company is located in the private science and technology park of Chuangye Road, Kangdian Town, Gongyi City, Henan Province, covering an area of more than 15,000 square meters, with 6 modern heavy-duty production workshops, advanced technology and perfect production management system. After more than 20 years of development, it has been exported to Serbia, Romania, Russia, Mongolia, Indonesia, Kazakhstan, Viet Nam, North Korea, Egypt, Ghana, Tanzania, South Africa, Canada, Chile, Bolivia, Mexico and other countries and regions.

The magnetic separator, ball mill, jaw crusher, hammer crusher, impact crusher, brick/block making machine,etc. produced by the company have been successfully applied at home and abroad. All of them are tracked and tested by quality inspection engineers; And the company has passed ISO 9001:2015 international quality system certification, ISO 45001:2018 quality, health and safety management system certification, ISO 14001:2015 environmental management system certification, five-star commodity after-sales service system certification, to ensure that users are provided with high-quality and reliable equipment.

The company can provide production line design according to customer requirements. Xiangrui Machinery pursues the business philosophy of "survival by quality, development by reputation", adheres to the production policy of "not accepting defective products, not producing defective products, and not producing defective products", and all equipment from casting - machining - assembly are checked by technical engineers at all levels, and strive to build a brand enterprise that satisfies users, so that customers can buy at ease and use comfortably! It has created more value for many enterprises and society.

FAQ

1.Q: Is your company a manufacturing company or a trading company?A: We are a direct sales factory, not an agent or trading company, quality and after-sales service are guaranteed.

2.Q: How to guarantee the quality of the machines?

A: Our products have passed ISO 9001-2000 certification. We have 20 years of experience in machine manufacturing and are constantly updating our technical concepts and applications.

3.Q: When do you ship?

A: We usually ship within 10 days after we receive full payment from the buyer.

4.Q: What are the payment terms?

A: Payments under $1000 require full payment. For payments over $1000, the advance deposit is 30% via T/T and the balance before T/T shipment is 70%. Other transaction options are also available.

5.Q: Can you provide videos?

A: We can send you a video, please contact me.

6.Q: What are your warranty terms?

A: We provide 12 months warranty for all quality issues.

7. Q: How do I install and maintain the machine?

A: We can provide you with videos, emails, pictures ..... , teach you to install or maintain the machine. If it is a large project, we can arrange an engineer to your country to help you install or maintain the machine. If you need spare parts, we can provide them free of charge or at cost price, but you need to pay the courier fee.

8.Q:Allocation and training of engineers?

A: We can provide manuals, working videos, installation videos and pictures first, or we can assign engineers to go abroad to install or train machines for users.

9.Q: Do you provide customized service?

A: We can provide customized service (color, LOGO, size, material, etc.).

10.Q: Can we visit your factory?

A: Yes, you can visit our factory anytime.

OUR SERVICES

1.24 hours online service.

2.Email: xiangruimachinery88@gmail.com

3.Can be customized according to customers' requirements.

4.Please check again before shipment.

5.Ship on time.

6.We can test the machine before shipment if customers need.

7.The more you need, the cheaper the unit price.

8.Help customers to ship.

3.Can be customized according to customers' requirements.

4.Please check again before shipment.

5.Ship on time.

6.We can test the machine before shipment if customers need.

7.The more you need, the cheaper the unit price.

8.Help customers to ship.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices