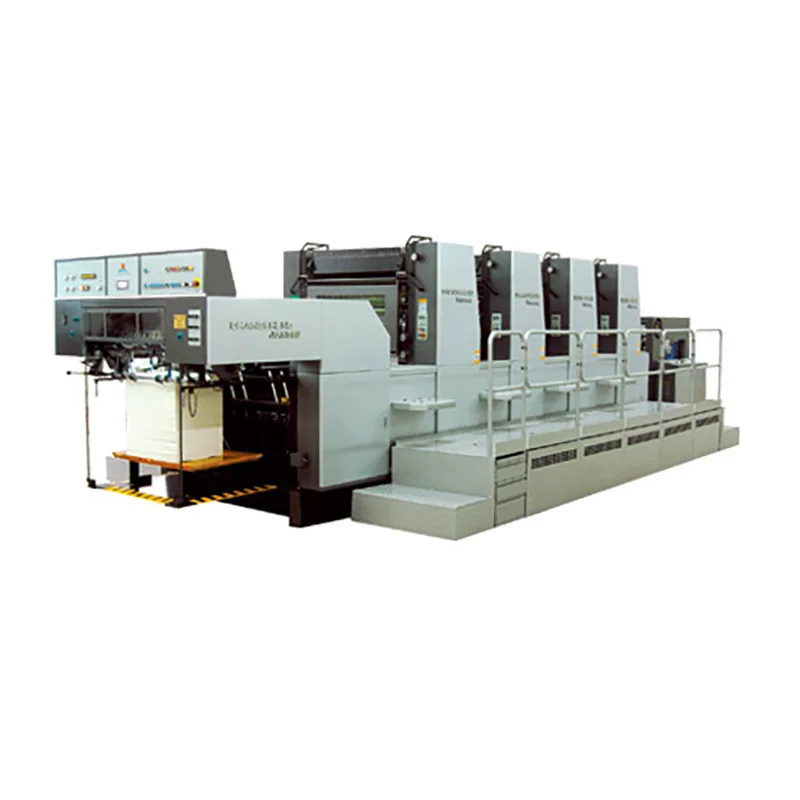

USED second hand Heidelberg Speedmaster SM524 four color offset printing machine offset printer made in germany

- Category: >>>

- Supplier: Weifang Swan Machinery Co. Ltd.Weifang Ltd.

Share on (1601346400537):

Product Overview

Description

Product Description

heidleberg Speed Master SM524 SM52 GTO52 offset printing machine

CP 2000 with AXIS CONTROL (Spectrophotometric Color Measurement)

AUTOPLATE - PRESET Feeder with Central Suction Tape - Low Pile

Delivery - ALCOLOR dampening - Technotrans Refrigeration -

Delivery - ALCOLOR dampening - Technotrans Refrigeration -

ALL Automatic washers (blanket, rollers and impression cylinders) -

Antistatic Device -

Antistatic Device -

Grafix Alphatronic 200 Powder Spray -

PLUS VERSION (possibility of Numbering and Perforating Unit at extra

cost) - Speed 15.000 Sheet per Hour -

cost) - Speed 15.000 Sheet per Hour -

STRAIGHT MACHINE - Can print until 0,5 mm

With the Speedmaster® SM 52, Heidelberg® offers you a modular press concept with a whole range of configurations from basic to highly automated. This wide array of options enables you to make focused and flexible decisions to ensure your press is geared towards your business model and specifi coperating requirements. This makes the Speedmaster SM 52 the ideal press for commercial printshops.

Get off to the ideal start with the feeder

The tried-and-tested suction tape feeder with central suction tape combines precision with reliability and ease-of-use. The suction head with combined lifting/ forwarding suckers and, in some confi gurations, speed compensated blast air reliably processes paper thicknesses of up to 0.6 mm (0.024 in). Lateral sheet separation blowers separate sheets more effectively and ensure smooth paper travel regardless of what printing stock is in use. Presettings can be used to input pull lay and front lay settings quickly and easily. Double sheet detectors and light barriers deliver maximum reliability in production and extremely s table conditions, even at top speed.

The right delivery confi guration for your needs.

When processing longer runs, the high-pile delivery means fewer pile changes need to be made. Control is via the high-performance Prinect Press Center control station or the convenient delivery control panel with touchscreen and jogwheel. Venturi nozzles in the sheet guide plate prevent sheets from being smeared and scratched during perfecting or workand-turn operations. The high-pile delivery can be equipped with the right dryer for any application.

The DryStar® Ink drying system gets you to the finishing stage faster. During coating applications, the extended high-pile delivery with DryStar Combination dryer ensures outstanding drying results.

The DryStar® Ink drying system gets you to the finishing stage faster. During coating applications, the extended high-pile delivery with DryStar Combination dryer ensures outstanding drying results.

The Prinect Press Center – more than just a control station.

The high-performance Prinect Press CenterTM combines the press control system and remote color and register control in a single central console. When changing jobs, the innovative, process-oriented operator guidance system Intellistart dramatically reduces makeready times, thereby boosting your productivity. The delivery control panel with touchscreen and jog wheel also ensures maximum ease of use. For presses with blade-type ink fountains, operation is via the compact Onpress Center at the delivery

The plate clamping system EasyPlate® with automatic positioning run makes plate changes straight forward and precise. AutoPlate ensures even quicker plate changes, thereby cutting makeready times dramatically. The combined washup device for blanket and impression cylinders and the automatic inking roller washup device deliver fast and thorough cleaning – and do so in an exceptionally economic and environmentally friendly way. Depending on your chosen confi guration, the Speedmaster SM 74 has either a Heidelberg ink fountain that can be controlled remotely or a laser-slit blade-type ink fountain. The speed-compensated dampening system Alcolor® achieves an incredibly thin fi lm of dampening solution and a consistent ink/water balance. The inking unit temperature control system CombiStar® ensures consistent printing conditions, cuts startup times and reduces waste.

Product Paramenters

Printing jobs

With the Speedmaster® SM 524, Heidelberg® offers you a modular press concept with a whole range of configurations from basic to highly automated. This wide array of options enables you to make focused and fl exible decisions to ensure your press is geared towards your business model and specifi c operating requirements. This makes the Speedmaster SM 74 the ideal press for commercial printshops.

Magazines

Booklets

Brochures

After-sales service

Pre-Sales Service

* Inquiry and consulting support.

* Visa for visit China support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Factory view

Contact Us

Mr Brian (Sales Manager) | ||

China warehouse | ||

Mobile/whatsapp | +86-18906368566 | |

Skype | lisakingling | |

Email | infoATswanmachinery.com | |

Website | www.swanmachinery.com | |

Address | No.2761 Heping Road,Weicheng District,Weifang,China | |

What Are Supplying | ||

Pre Press | CTP,Cutting machine | |

Printing press | Single color,Double Color,Four Color Size:470mm,520mm,560mm,660mm,720mm,1020mm | |

Post Press | Paper folder,Laminator,Bindery Machines,Collator,Stitching Machine,Die cutting machine,UV Dryer and coater | |

Brand | Chinese Brand(Warehouse in China),European Brand(Warehouse in Germany) | |

Recommend Products

We Recommend

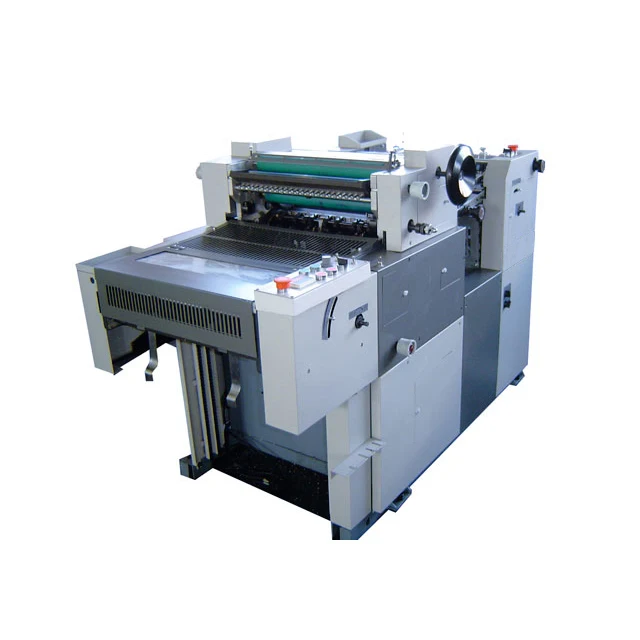

4 Color Offset Printing Machine Price Shinohara Printing Machine Offset

$28,000.00-36,000.00

MACS Four Color Offset Printing Machine

$800,000.00

New Arrivals

New products from manufacturers at wholesale prices