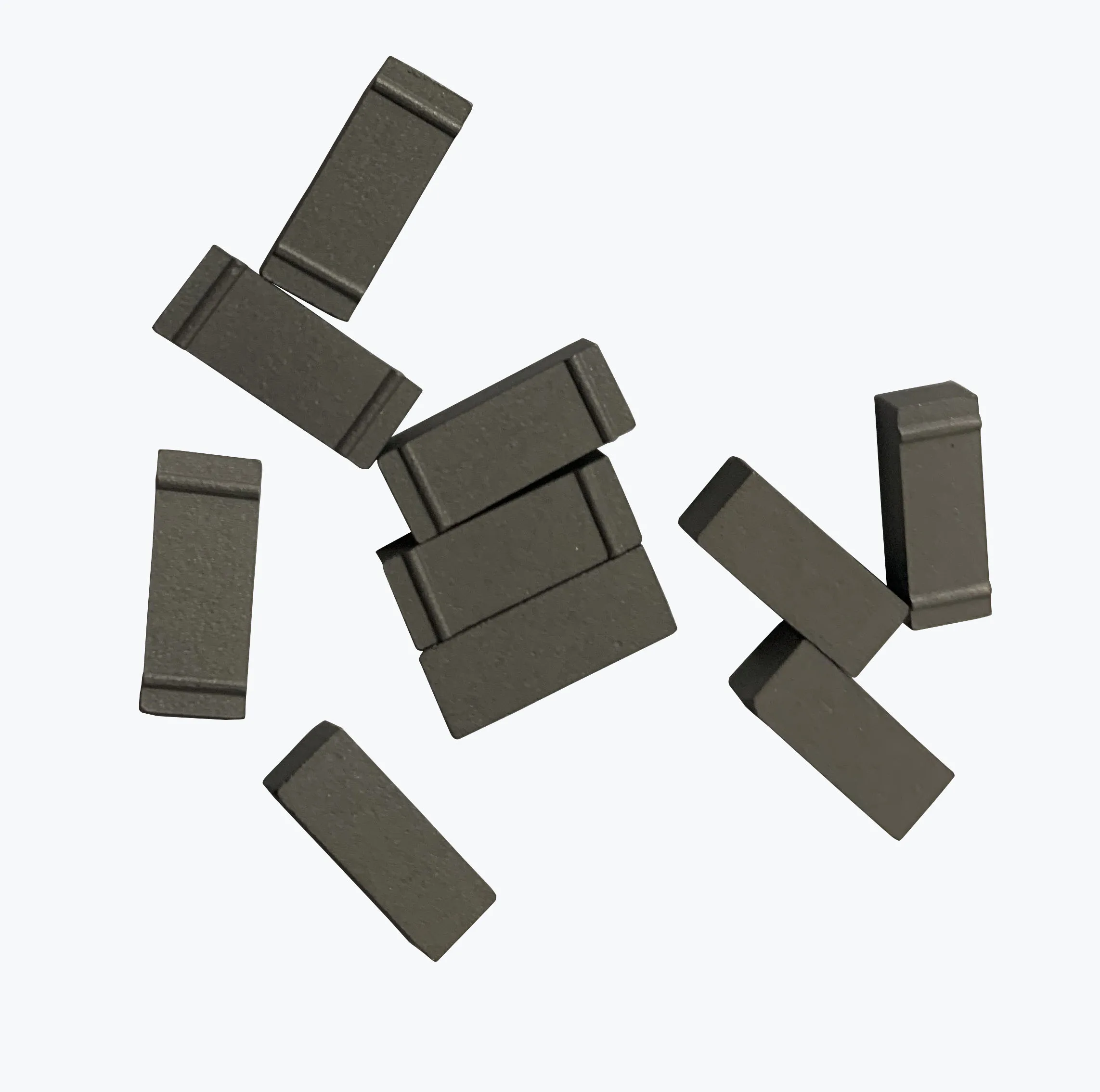

Cemented tungsten carbide ribbed magnetic inserts for HF3000 Hardfacing

- Category: >>>

- Supplier: Zhuzhou Hongtong Tungsten Carbide Co. Ltd.Zhuzhou Ltd.

Share on (1601348232735):

Product Overview

Description

Products Description

Feature:

Tungsten carbide tiles for Radial Bearings

carbide tiles sheets TC bearing for stabilizer

Carbide TC bearing tiles sheets for stabilizer

Carbide TC bearing tiles

Tungsten carbide tiles for Radial Bearings

carbide tiles sheets TC bearing for stabilizer

Carbide TC bearing tiles sheets for stabilizer

Carbide TC bearing tiles

Product Application

Our carbide are used as YG8D YG9D YG11C wear parts tungsten carbide block, wear resistance tungsten carbide block to reduce wearing away and protect the machine parts, etc.

Our carbide are used as YG8D YG9D YG11C wear parts tungsten carbide block, wear resistance tungsten carbide block to reduce wearing away and protect the machine parts, etc.

Advantage

1.We are factory

2.ISO 9001:2015 Certificated

3.With 100% tungsten carbide raw material

4.Advanced technology, automatic pressing, HIP sintering and strict products quality inspection

5.Free samples provided

6.Make to customer’s requirements

7.Products could be precision grinded and polished

8. Delivery in time

9. Good after-sales service

1.We are factory

2.ISO 9001:2015 Certificated

3.With 100% tungsten carbide raw material

4.Advanced technology, automatic pressing, HIP sintering and strict products quality inspection

5.Free samples provided

6.Make to customer’s requirements

7.Products could be precision grinded and polished

8. Delivery in time

9. Good after-sales service

Carbide tile size | L MM | W MM | H MM | |||

1 | 6 | 5 | 3 | |||

2 | 6 | 5 | 4 | |||

3 | 13 | 5 | 3 | |||

4 | 13 | 5 | 4 | |||

5 | 20 | 5 | 4 | |||

6 | 25 | 5 | 3 | |||

7 | 25 | 5 | 4 | |||

8 | Φ9.5 | 3 | ||||

9 | Φ6 | 3 | ||||

10 | Φ6 | 2 | ||||

Note: The unlisted sizes are avaiabe upon customer's requirement. | ||||||

Tungsten carbide tile application

Details Images

Product Paramenters

Grade | Representative Performance Index | Recommended Applications | ||||

Hardness | Density | Traverse Strength N/mm2 | ||||

(HRA) | (g/cm3) | |||||

YG8D | 89.7 | 14.63 | 2150 | Used as insert of TC bearing and coal drill bits, and as wear parts of cone bits. PDC bit and stabilizers. | ||

YK8 | 89 | 14.5 | 1850 | Used as insert of TC bearing and coal drill bits, and as wear parts of cone bits. PDC bit and stabilizers. | ||

YL1 | 91 | 14.75 | 2050 | Used as insert of TC bearing and coal drill bits, and as wear parts of cone bits. PDC bit and stabilizers. | ||

YG8C | 88.5 | 14.65 | 2200 | Used for auger of excavators and coal machines to drill hard formations, also as buttons of rotary drill bits and drag bits to drill soft rock formations. | ||

YG9C | 88 | 14.5 | 2250 | Used for auger of excavators and coal machines to drill hard formations,also as buttons of rotary drill bits and drag bits to drill soft rock formations. | ||

YG11C | 87.5 | 14.3 | 2300 | Used as auger of excavators and coal machines, also as carbide head cutters of boring machines. | ||

Please feel free to contact me for any inquiry or question. We'll reply you initially within 24 hours.

Tina Xiang

Mail: tina<@>zzhthj.com

Whatsapp /Wechat/ Mobile :+86 18273385802

QQ:305645293

Company Profile

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, Military, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes, Finished Products and Packaging to ensure high quality products output.

We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes, Finished Products and Packaging to ensure high quality products output.

Our Main products include : Carbide dies, Carbide teeth,Carbide ball and seat, Carbide plates for agriculture wear parts, Carbide gripper,Strips, Bushings, Seals ring, Brazed tips, Nozzles, End Mills & Drill Bits, CNC inserts, Rotary Burrs, Grits, Customized carbide cutter: Woodworking tool cutter, V-cutter, mining tool, Any customized carbide products are acceptable.

Product packaging

About packing:

Inner packing : plastic box, paper box or plastic bag

Outer packing: paper carton, wood carton, metal pail

Also can according to customer demand

Outer packing: paper carton, wood carton, metal pail

Also can according to customer demand

Shipping:

We support: shipping,air fright, road transport, and UPS, DHL, FEDEX,TNT, EMS and other commonly used some of the logistics.

FAQ

Q1 : Are you Factory or trading company ?

We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What’s your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What’s your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on

We Recommend

New Arrivals

New products from manufacturers at wholesale prices