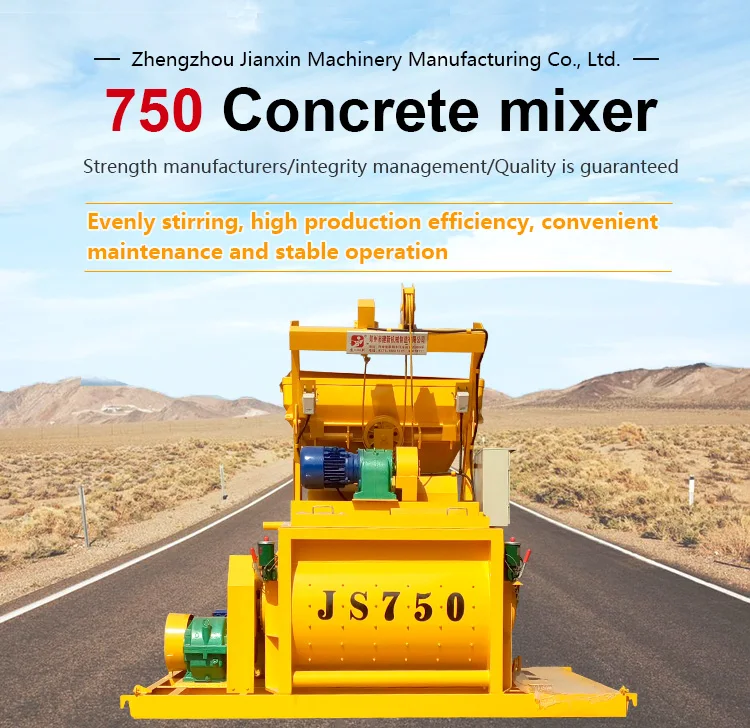

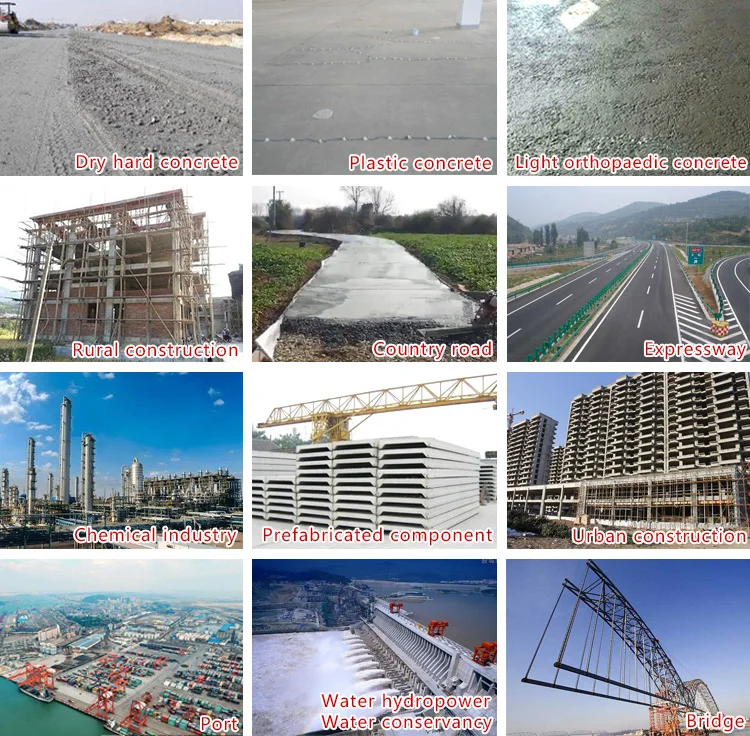

Hot Sale Concrete Machine Mixer with 750l China concrete mixer

- Category: >>>

- Supplier: Zhengzhou Jianxin Machinery Co. Ltd.Zhengzhou Ltd.

Share on (1601350004003):

Product Overview

Description

JS750 concrete mixer Mixing system

JS750 concrete mixer mixing system consists of motor, pulley, gearbox, gear, stirring device, mixing drum and other components. The main motor is connected to the secondary gear reduction box through a belt, and finally the two horizontally-connected stirring shafts are respectively rotated by the two pairs of open gears at the same speed.

JS750 concrete mixer Feeding system

When the JS750 concrete mixer is feeded, the mixture to be mixed is placed in the hopper, the feeding system is started, and the wire rope pulling hopper is climbed upward. When climbing to a certain height, the hopper enters the feeding rack, the door is automatically opened, and the material is discharged into the mixing drum through the funnel.

JS750 concrete mixer Discharging system

The discharging system is located at the bottom of the JS750 concrete mixer and is unloaded by a manual push rod. According to customer requirements, the mixer can be produced in the form of electric push rod discharge. The connection between the discharge door and the mixing drum is sealed with a sealing plate, and the position of the sealing plate can be adjusted to ensure the purpose of sealing.

JS750 concrete mixer Electrical System

The electrical control system needs to control the main drive motor of the JS750 concrete mixer, the motor of the water supply system, the feeding and unloading of the motor. All electrical control components are located in the distribution box. The electrical components in the distribution box are installed on an iron plate, which is safe and reliable, and convenient for operation and maintenance.

| project | JS750 |

| Discharge capacity | 750L |

| Feed capacity | 1200L |

| Theoretical productivity | ≤35m³/h |

| Maximum granule of aggregate (Lithotripsy/Pebble) | ≤40/60 |

| Speed of mixing blade | 31(R/min) |

| 2×7(number) | |

| Power of agitator | 30KW |

| Improve motor power | 7.5KW |

| Pump motor power | 1.1KW |

| Shape size (Length, width and height) | 5025×3100 ×5680 |

Zhengzhou Jianxin Machinery Manufacturing Co., Ltd. is a high-end technology enterprise that integrates R&D, manufacturing, sales, and service. It has been established for more than 30 years, and it has always adhered to the production of equipment for concrete mixing plants. It is a development project for China's construction industry. Provide high-quality high-end concrete production equipment and construction programs.

Professional technical and service teams have provided inexhaustible motivation for building a new century-long foundation. At present, all new brand equipments are designed, produced, assembled and tested in accordance with the ISO9001 international quality certification system standards. Currently, they have been sold in more than 20 countries and regions at home and abroad, and treat each customer seriously, providing them with quality equipment and services. In order to improve the interests of customers, it is the compliance of the establishment of new standards. Quality is the lifeblood of products, and high-quality after-sales service is our top priority.

FAQ

Q How about the quality of your products?

A Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.Chinese top brands or world grade brands like Siemens motors etc are equiped.

Q How about the price?

A As a manufactory, we can give you lower price than trade companies. Besides, customers from Alibaba can get a discount and ensurance.

Q Do you provide after-sale service?

A Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.It usually takes 1-3 days for training , 10-15 days for installation,1-2days for commission,1-2days for pre-operation.

Q Do you provide equipment operation training?

A Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training.It's about 90-120 usd a day.

Q Can you test our samples?

A Yes. You can send your samples to us for test and analysis.

Q How long it takes to do all the installation

A It's at most 5days processing and manufacturing for single machine,for production line,at most 15days.

Q Can we visit your factory?

A Yes. You can visit our factory at anytime you want.

We Recommend

Factory Outlet Cement Mixing Machine Concrete Mixer Trucks Concrete Mixer

New Arrivals

New products from manufacturers at wholesale prices