Schaftmanschetten Aus Rostfreiem Stahl, Din705 Nylon Manschette, Geteilt Mit Bohrung, Geteilter Doppelter Aluminium Gemeinschaft

- Category: >>>

- Supplier: Chengdu Machining Technology Co. LtdChengdu Ltd

Share on (1601351135875):

Product Overview

Description

We are Manufacturer of Industrial automation parts, Our shaft collars manufactured with CNC precision. We can also produce them in other materials like stainless steel, titanium alloy, aluminum alloy, mid steel, and carbon steel to match your requirements. We offer eight types of imperial shaft collars,including set screw shaft collar, quick release shaft collar, 1-piece shaft collar, 2-piece shaft collar, D-profile shaft collar,threaded shaft collar, Hex shaft collar, and double wide shaft collar& shaft coupling,etc. We can manufacture all sizes of shaft collars as per your request.

Nice to see you!

| ONE-PIECE: Carbon steel and black oxide | TWO-PIECES: Carbon steel and black oxide | SET-SCREW: Carbon steel and black oxide |

| Bore size: | Bore size: | Bore size: |

6mm,8mm,10mm,12mm, 13mm,14mm,15mm, 16mm,18mm,20mm,22mm,25mm, 28mm,30mm,35mm,38mm,40mm, 45mm,50mm,60mm,70mm,80mm. | 1mm,6mm,8mm,10mm,12mm, 13mm,14mm,15mm,16mm, 18mm,20mm,22mm,25mm,28mm,30mm, 35mm,38mm,40mm,45mm, 50mm,60mm,70mm,80mm. | 1mm,6mm,8mm,10mm,12mm,15mm, 16mm,20mm,22mm,24mm, 25mm,28mm,30mm,32mm, 35mm,40mm,50mm. |

Company Information

Certificate

Our Equipment

Testing Equipment

Contact Us

Upload your drawings to get an instant online fabrication quote on custom-metal prototypes and production parts.

Company Information

Factory Show

|  |  |

| Laser Engraving | Laser Cutting | Drilling |

|  |  |

| Pressing Rivet | Oil Hydraulic Press | Bending |

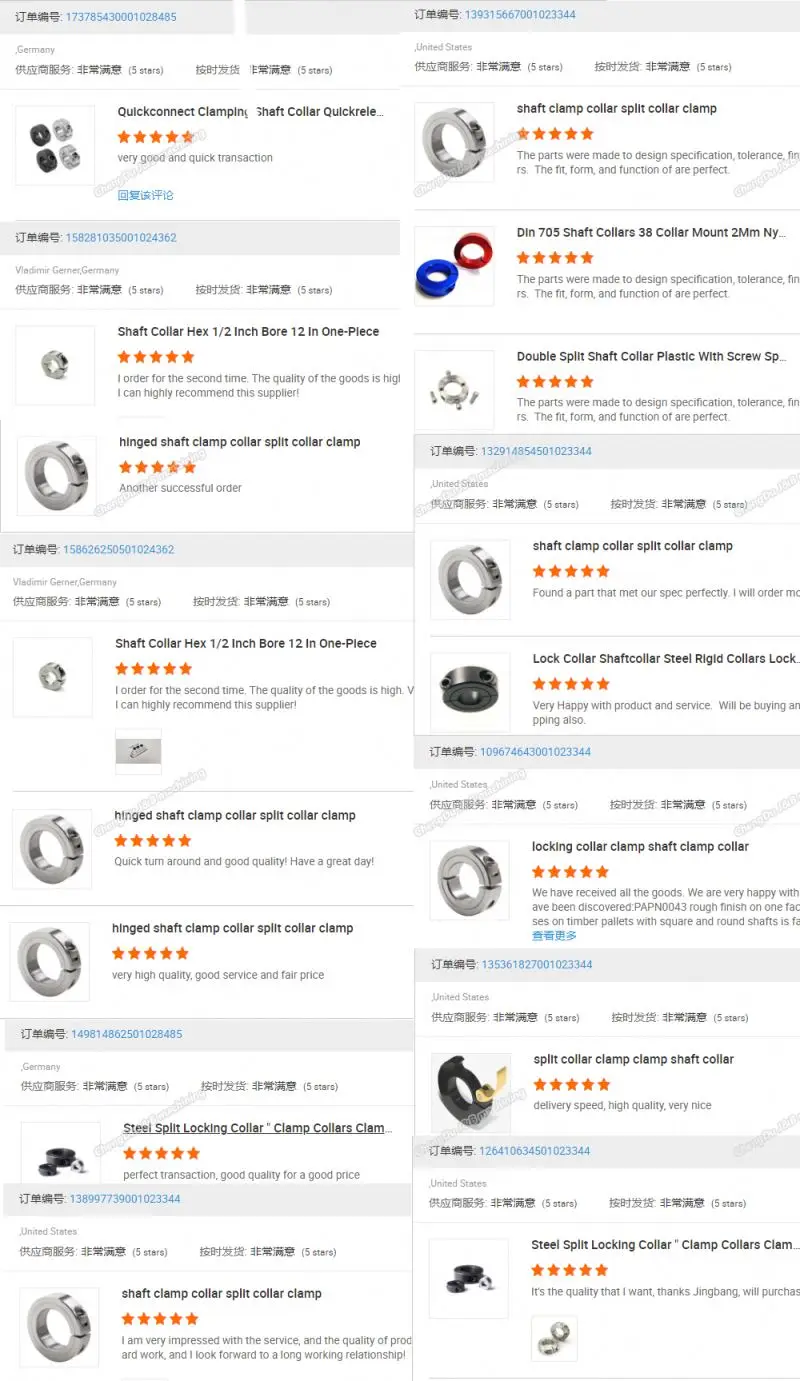

Customer Reviews

FAQ

1. How can we ensure our product quality?

A: 1, After order confirmed, we have a meeting with the main peoples who work for the workshop before production, investigate all the workmanship and some technical problems, ensure all of them have related ways tosettle and control.

2, Inspect all the materials when arrived, ensure they will be catch up customers' requirements.

3, Inspect the semi-finished goods.

4, Inspect the finished products.

5, Final inspection when packing up all the goods. if there are not any problems for this step, our QC will issue the inspection report and release these products.

2. How about your productivity?

A: We have factories in China, Chengdu, Chongqing, and Shenzhen,which are strong enough to guarantee our customers' quality andtimeliness.

3. What are the terms of payment?

A: Payment terms: Paypal, Western Union, Offshore Account or as your requirement. Payment terms are flexible for us in accordance with specific conditions. Generally, we advise a 30% TT deposit, balance is paid before shipment.

4. What will you do after-sales ?

A: When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help

2, Inspect all the materials when arrived, ensure they will be catch up customers' requirements.

3, Inspect the semi-finished goods.

4, Inspect the finished products.

5, Final inspection when packing up all the goods. if there are not any problems for this step, our QC will issue the inspection report and release these products.

2. How about your productivity?

A: We have factories in China, Chengdu, Chongqing, and Shenzhen,which are strong enough to guarantee our customers' quality andtimeliness.

3. What are the terms of payment?

A: Payment terms: Paypal, Western Union, Offshore Account or as your requirement. Payment terms are flexible for us in accordance with specific conditions. Generally, we advise a 30% TT deposit, balance is paid before shipment.

4. What will you do after-sales ?

A: When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help

We Recommend

New Arrivals

New products from manufacturers at wholesale prices