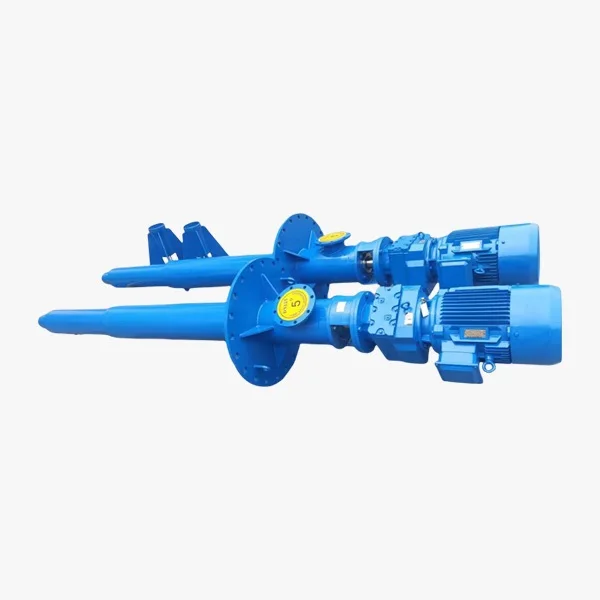

Immersed Vertical Progressive Cavity Single Screw Pumps with Bracket or Flange / Vertical progressive cavity pump

- Category: >>>

- Supplier: Hton Machanical Equipment (tian Jin) Co. Ltd.Hton Ltd.

Share on (1601353424971):

Product Overview

Description

Description of immersed vertical progressive cavity pumps with bracket or flange:

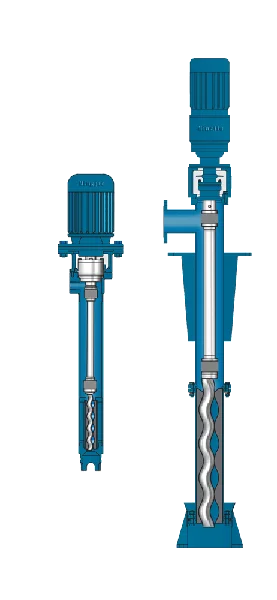

Compared with horizontal screw pumps, vertical screw pumps work in an upright position, and the inlet and outlet can be used interchangeably. The biggest difference is that the stator at the suction inlet is trumpet-shaped, and the support method can use bracket support or ring installation, or be equipped with a forklift for movement.

By adjusting the length of the pump body, it can be installed in pools or tanks of different depths. The rotor and stator parts are inserted into the liquid, while the reduction motor is located above the liquid level and does not come into contact with the medium; the pump's suction inlet is located at the bottom of the pool and is fixed by legs, making its operation very stable.

The vertical pump has a small cavitation allowance and is suitable for pumping materials from barrels, tanks, boxes, and troughs. It is especially suitable for use in narrow spaces and dangerous culverts. In addition, when the bottom of the barrel cannot discharge materials through the pipeline, or the materials may cause pollution to the environment and drinking water, our vertical pump can meet your needs.

Technical Parameters

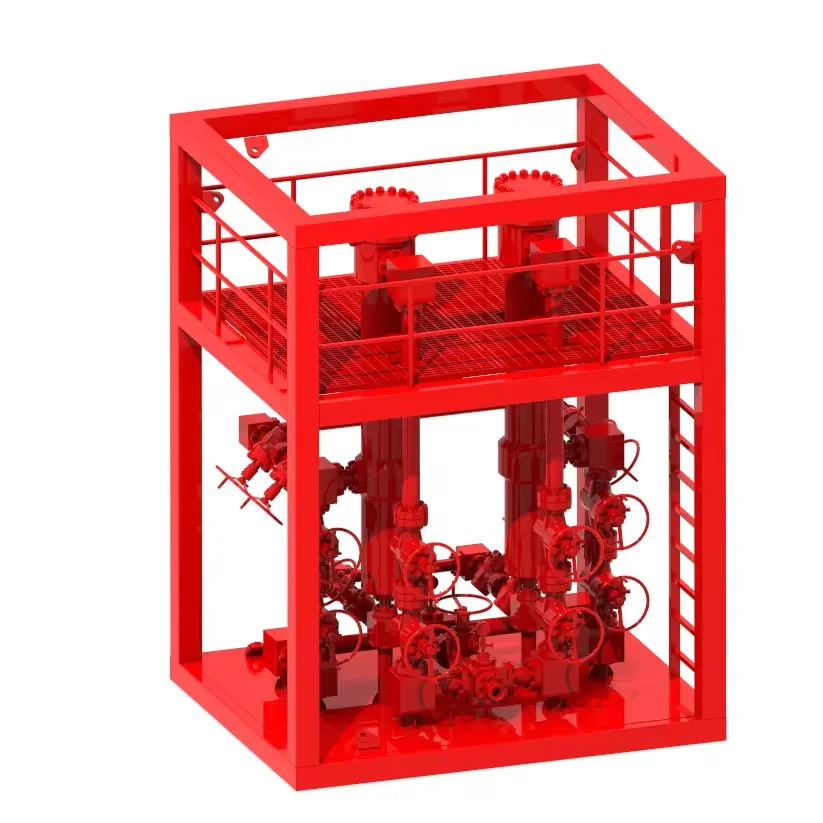

The flow rate can reach up to 140m³/h, and the pressure can reach up to 24bar. The barrel pump flow rate can reach up to 3m³/h, and the pressure can reach up to 8bar. According to the actual situation, various modifications can be made to the vertical pump, and the depth of the submerged working point can also be adjusted as required.

Features:

l Multiple installation methods (bracket mounting, hoist ring mounting, wall mounting, fixed by lifting trolley, etc.)

l Uses a flared stator, strong self-priming capability

l Long conveying distance

l Can operate under high conveying pressure and high capacity

l Capable of pumping a variety of substances

l Flow rate can be proportionally adjusted

l Long lifecycle, low cost

l Easy disassembly and maintenance, time-saving

l Perfect measurement accuracy

Working Principle:

The progressive cavity pump belongs to the positive displacement pump category. It relies on the interference fit between the eccentrically moving rotor and the stationary stator to form sealed cavities that do not communicate with each other. As the rotor rotates inside the stator, these sealed cavities move axially from the inlet end to the outlet end of the pump, thereby enabling the medium inside the sealed cavities to be conveyed through the pump.

Application Fields

l Environmental Protection: Transporting industrial wastewater, domestic sewage, and sludge turbid water containing solid particles and short fibers, especially suitable for oil-water separators, plate and frame filter presses, and other equipment.

l Shipbuilding Industry: Used for transporting residual oil, cleaning tanks, sewage, seawater, etc.

l Petrochemical Industry: Used for transporting various oils, especially crude oil.

l Textile Industry: Used for transporting synthetic fiber liquids, viscose liquids, dyes, nylon powder, etc.

l Pharmaceutical and Daily Chemicals: Transporting various viscous pastes, emulsions, and various ointments and cosmetics.

l Canned Food Industry: Transporting various viscous starches, edible oils, honey, sugar syrup, fruit pulp, cream, fish, and leftovers.

l Brewing Industry: Various fermented viscous liquids, concentrated distiller's grains, grain product residues, various sauces, fruit pulps and mucus containing a large amount of solid substances, etc.

l Construction Industry: Spraying and transporting of cement mortar, lime mortar, paint, and other slurries.

l Metallurgy and Mining Industry: Used for transporting oxides and wastewater, mine drainage, and liquid explosives, etc.

l Chemical Industry: Transporting various suspensions, fats, colloidal slurries, adhesives, papermaking, printing, high-viscosity inks, pulp black liquor, PVC polymer plastic paste, various concentrations of pulp, short fiber slurries, etc. Sauces, condensed milk, cream, chili sauce, puree, chocolate, honey, etc.

Installation Forms:

· Horizontal

· Vertical

· Barrel Insertion

· Vehicle-Mounted

· Inclined

· Backpack

Contact Informations:

Company: Hton Mechanical Equipment (Tianjin) Co.,Ltd.

Contact : Rowena Song (Export Department)

M. Phone: 0086-130 3434 1829 ( We-chat / Whats App )

We Recommend

New Arrivals

New products from manufacturers at wholesale prices