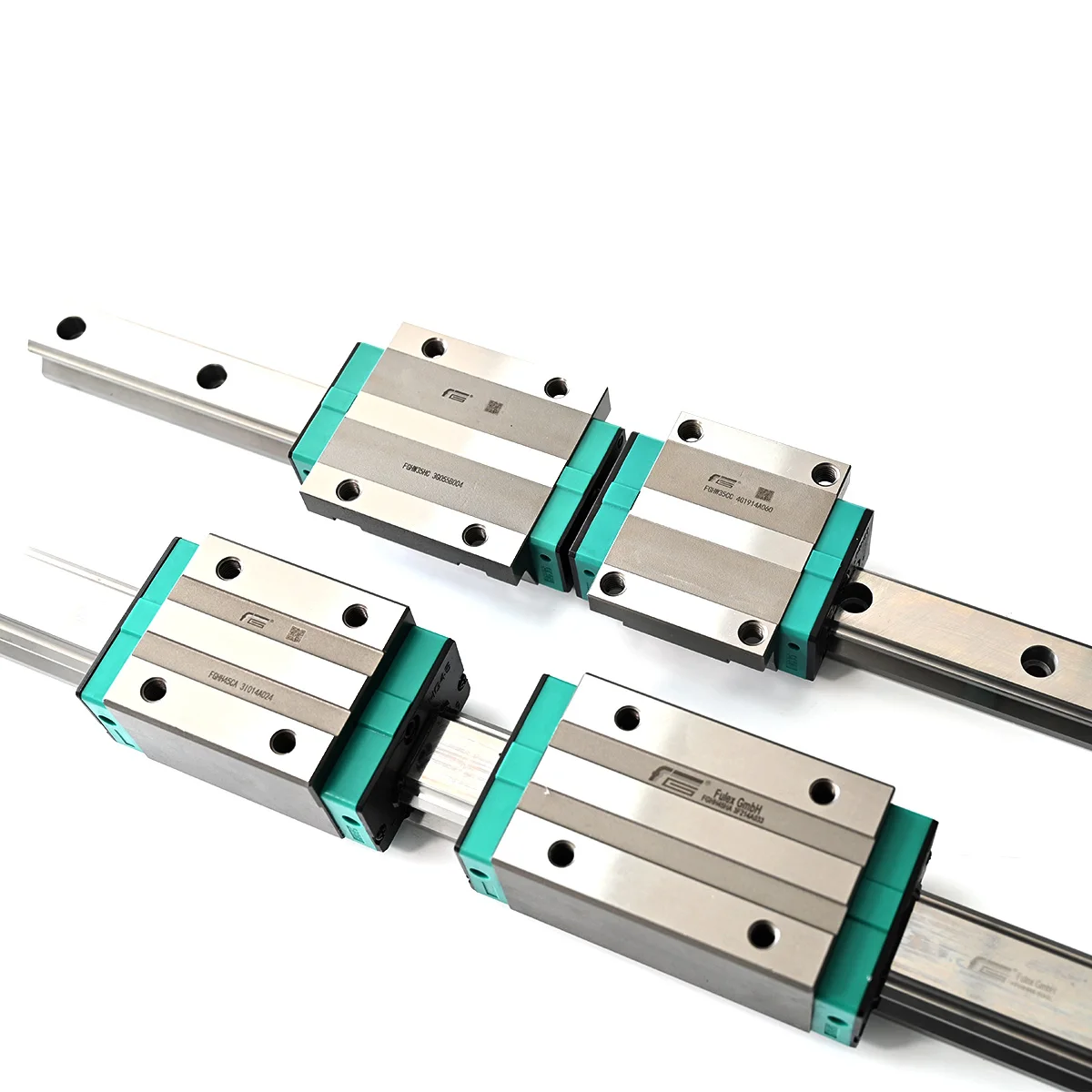

FGHR45R2500CHigh load high rigidity and high precision Quick delivery linear guide rail manufacturers sell CNC industry directly

- Category: >>>

- Supplier: Shandong Jieyin Electromechanical Technology Co. Ltd.Shandong Ltd.

Share on (1601354526430):

Product Overview

Description

Linear guide rail is a kind of mechanical transmission element that moves by sliding load on the guide rail. It consists of slider, guide rail and ball. The slider is equipped with balls, which slide on the guide rail by rolling, so that the guide rail has high-precision linear motion. The slider and guide rail are usually made of high-strength alloy steel or S55C carbon steel. Through precise machining and heat treatment, their surfaces have high hardness and low friction coefficient. This design makes the linear guide rail have the characteristics of high positioning accuracy, high speed and wear resistance

| specifications | FGHR45R | |||||

| Slider material | SCM420H alloy steel | |||||

| Linear guide rail material | S55CCarbon Steel | |||||

| Matchable slider type | Quadrilateral heavy load,Quadrilateral overweight load,Flange heavy load,Flange overload | |||||

| accuracy class | C | |||||

| advantage | Four-row single circular arc tooth contact linear guide rail, and at the same time integrate the heavy-duty precision linear guide rail with optimized structural design, which improves the load and rigidity ability; It has the characteristics of four-direction equal load and the function of automatic centering, which can absorb the assembly error of the installation surface and obtain the requirement of high precision. | |||||

| length | Custom-defined, can accept multi-segment splicing. | |||||

| Splicing process | End grinding butt joint, the error is controlled within 5 wires. | |||||

| Application | Machining center, injection machine, machine tool, punch, precision machining machine, automation device, heavy cutting machine, transportation equipment, marble cutting machine, measuring instrument, grinder. | |||||

Shandong Jieyin Electromechanical Technology Co., Ltd. was established on November 4, 2014, located in Jinan City, Shandong Province. The company focuses on the mechanical transmission industry and is a comprehensive company that integrates production and sales. Its products include slides, screws, modules, racks, etc. Our company is a strong agent of Fulei brand, adhering to the service concept of "customer first", serving every customer with heart, resolutely implementing product quality, strictly controlling high requirements, and striving to provide customers with convenient, fast, high standard and high-quality services.

We firmly believe that quality creates a brand, and integrity shapes the future

Our vision is to make the company a leading and world-class revitalized enterprise in the industry

Let all customers benefit from the company

Benefit all employees from the company

| 1. Before installing the linear guide rail, check the geometry, size and cleanliness of the guide rail. To ensure that the geometric shape of the guide rail meets the design requirements, the size is accurate, the surface is smooth, and the installation foundation of the guide rail is flat, rigid and free of sundries. Before installation, it is necessary to carefully clean the surface of the guide rail to avoid the influence of sundries on the motion accuracy. | ||||||

| 2. When installing the linear guide rail, you need to use professional installation tools to ensure that the parallelism and verticality of the slider and the guide rail meet the design requirements. For the equipment with long axis or multiple guide rails, the relative position of each guide rail should be adjusted to meet the design requirements. | ||||||

| 3. During operation, it is necessary to reasonably select the load and stroke of the guide rail to avoid exceeding its load range. At the same time, the weight of the slider should be balanced to prevent tilting or rusting. | ||||||

| 4. During use, the guide rail should be maintained regularly to clean up dust and foreign objects. In case of poor sliding or abnormal sound, inspection and maintenance are needed. At the same time, we should pay attention to waterproof, moistureproof and anticorrosion to ensure the long-term service life of the guide rail. |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices