Industrial commercial stainless steel meat salt brine injector beef chicken Injection machine for Sale

- Category: >>>

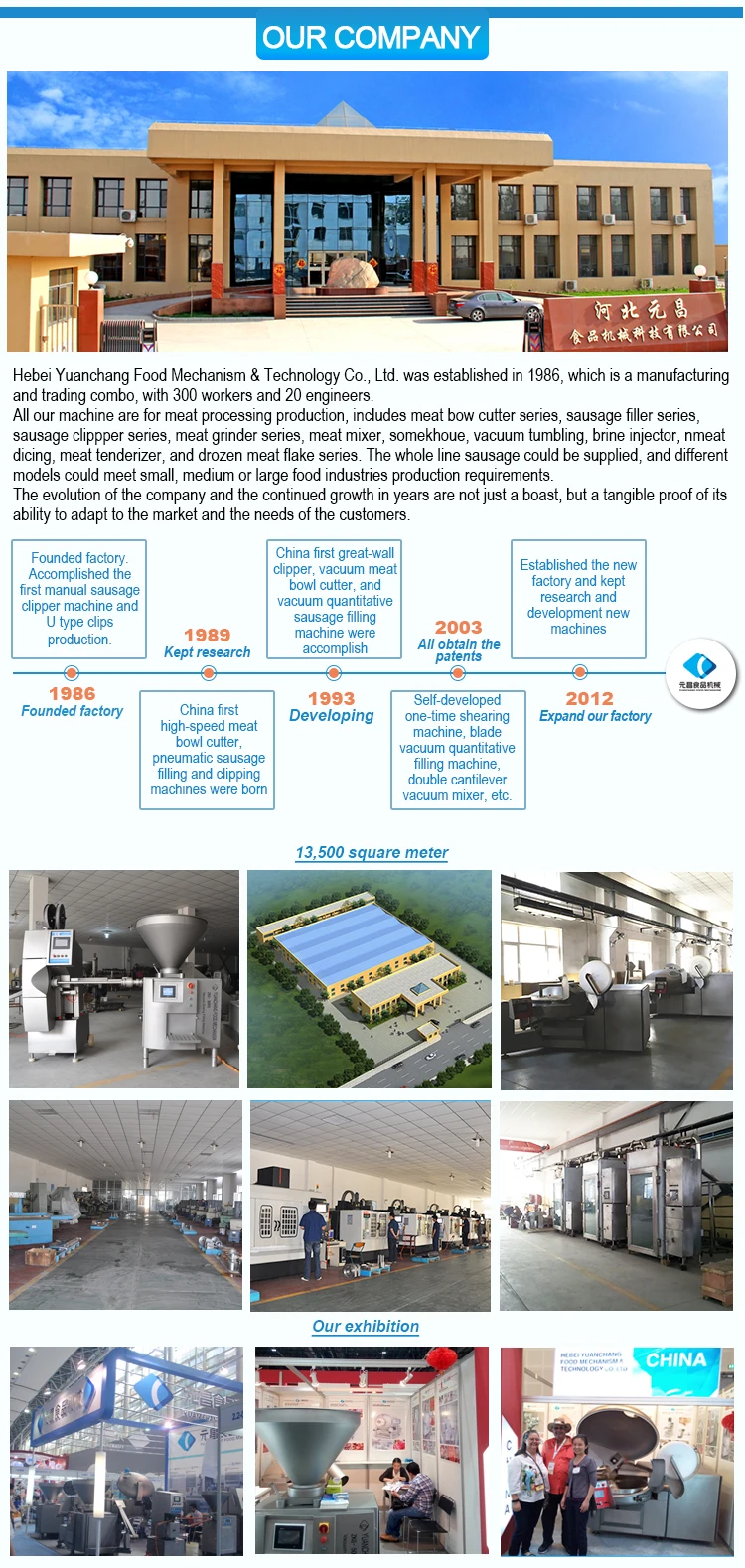

- Supplier: Hebei Yuanchang Food Mechanism & Technology Co. Ltd.Hebei Ltd.

Share on (1601355295965):

Product Overview

Description

ZSJ-140 Saline Injector Machine For Chicken Breast Brine Injection

YC Mechanism Meat Brine Injector ZSJ-72. ZSJ-180. ZSJ-360

Meat mince and emulsion injection production line

Modular construction,replaceable syringe bridges,can be changed quickly and easy to clean.

No mechanical adjustments are required to switch from one product to another

Throughout the process,the constant linear velocity of the needle achieves a consistent brine distribution.

The formulation program has process parameters such as product height and injection depth,pressure,etc

Model | Capacity (T/h) | Power (kw) | Injection pressure(Mpa) | Stroke (mm) | Injection speed (Times/Min) | Needle Quantity(PCS) | Step Space(mm) | Injection Rato(%) | Agitating Tank Volume(L) | Weight (Kg) | Size (mm ) |

ZSJ-72 | 0. 5~1 | 5.3 | 0.4 ~1.0 | 120 | 16/24 | 72 | 10-80 | 60~80 | 110 | 510/ 55 | 1450*900*1700 |

ZSJ-180 | 3-5 | 13.5 | 0.4 ~1.0 | 30-190 | 10-65 | 180 | 3-Speed Adjustable Servo Drive | 5-100 | 300 | 1200/ 180 | 2980x1660x2165 |

ZSJ-360 | 4-8 | 21 | 0.4 ~1.0 | 30-190 | 10-65 | 360 | 10-180 | 500 | 2000/ 240 | 3350x1660x2165 |

Meat mince and emulsion injection production line

New process integration system for meat emulsion injection production

Involved in the field of brain/emulsion injection of meat products

Integrated production line for filtration ,re-emulsification and tenderization , refrigeration and cooling,and sterilization of injected materials.

Equipped with a CIP cleaning system,dynamic weighing measurement of feeding and discharging materials,realize automated production through ICS intelligent control system.

Preparation,emulsification,cooling,injection,cleaning, sterilization Redefine flexibility,accuracy and hygiene in material injection.

Seamless integration of upstream and downstream operating systems

Complete process control ensures consistent color and taste of the product ,prolong shelf life,reduce costs and increase efficiency.

1. Are you a factory or trading company?

We are the SGS and BV certificated manufacturer, specialized in meat and sausage processing machines field for 32 years.

2. How about the product quality?

We adopt excellent SUS304 as machine material.

Each machine will be tested more than 24 hours before delivery to you.

All electrical parts are used reliable and famous brand, which works with us over 20 years.

3. What about the warranty and after-sale service?

Our machine has 1-year guarantee, whole life technical support

Engineers are available to serve overseas.

4. Are you providing training about machine installation and operation?

Yes, our engineer can teach your workers in our or your factory.

5. Is it possible to use our LOGO or special custom design?

Yes, we have a professional technology team for new research and development.

6. How long the lead time is?

Usually 2-9 weeks, depends on the machine you ordered.

7. What is the price term and payment method?

We can quote EXW, FOB, CIF and CNF price. And you can pay us by T/T, L/C or Western Union.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices