Qingdao Hiparter Custom Cutting Mould Forming Press Mold Steel Deep Drawing Progressive Die From China Professional Factory

- Category: >>>

- Supplier: Qingdao Hiparter Metal & Plastic Products Co. Ltd.Qingdao Ltd.

Share on (1601355881275):

Product Overview

Description

Qingdao Hiparter Metal & Plastic Products Co.,Ltd

Hiparter is a professional manufacturer of stage metal stamping dies and progressive stamping dies, committed to die design, die manufacturing and product production.

Products Description

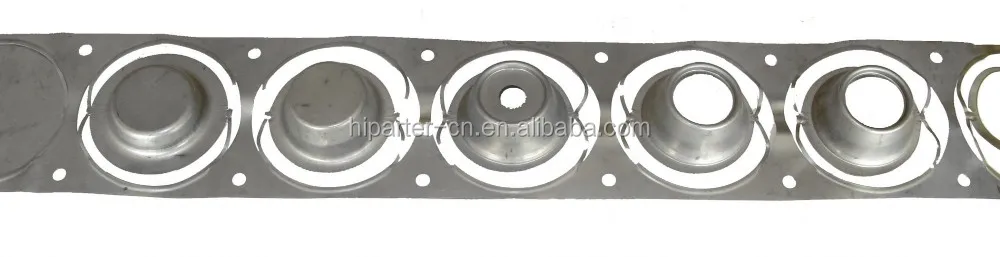

We can make kinds of stamping dies, such as stage stamping dies, progressive tooling, transfer stamping tooling, etc.

Die Type | Progressive Stamping Die, Stage Stamping Die, Transfer Stamping Die | ||||

Die Material | SKH-9, DC53, SKD11, Cr12Mov, Cr12, 45# | ||||

Part Material | Cold steel, Galvanized steel, Stainless steel(SUS301, SUS304, SUS430 ) , etc. | ||||

Standard Part | MISUMI, PUNCH, FIBRO, DAYTON, DME, etc. | ||||

Manufacturing Machinery | Milling, Grinding, Boring, CNC, EDM, WEDM, Precision Flat Milling, Saw Machine | ||||

Press Machinery | 45T~800T, Press machine, Punching machine, Forming machine | ||||

Inspection Machinery | CMM, Vision Projector, Micro-callipers, Laser Scanner, Alloy Analyzer | ||||

Forming Way | Punching, Blanking, Piercing, Bending, Forming, Deep Drawing, etc. | ||||

Die Precision | High precision machining, minimum 0.02mm. | ||||

Lead Time | 6 weeks for die buidling, after the die structure drawing confirmed. | ||||

Delivery | By sea or air, By air around 2-5 days, By sea around 10-30 days. | ||||

Metal Stamping Die

Progressive Stamping Die

Transfer Stamping Die

Related Products

Our Advantages

We adhere to total solution service: product design optimization→ stamping die design→ stamping die manufacturing→ stamping die debugging→ product inspection→ die specification manual sharing→ after-sales support.

1. Stamping Die Design Capacity

1)3D and CAD/CAM/CAE design

2)More than 10 stamping tooling design engineers

3)During nearly 20 years of development, Hiparter insists on providing high-standard and high-quality stamping dies and support.

2. Stamping Die Manufacturing Capacity

1)Stamping die machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

3. Stamping Die

Production Capacity

1)45T~800T press machines more than 24 sets

2)Equipped with Press machine and hydraulic machine

3)Material feeder for progressive die 8 sets

4)Experienced technology engineers and well trained workers

5)Almost all the stamping die trial completed in-house.

4. Stamping Die

Quality Control Capacity

1)Full equiped with inspection machines, including CMM, projector, 3D scanner, Blue scanner, White scanner, Alloy analyzer, etc.

3)Inspection report for stamping dies and stamping parts

2)CMM inspection for the die cores and inserts.

4)In order to control the quality of the stamping dies, we have a strict quality control mechanisms.

5. Stamping Die

Delivery Control Capacity

1)2~6 weeks lead time

2)Update stamping die building progress to customer weekly, control project progress to ensure project schedule

3)Exported to over 30 counties

4)With more than 10 years of import and export experience, cooperate with powerful logistics companies and major express

companies, to ensure smooth export and delivered to customers asap.

companies, to ensure smooth export and delivered to customers asap.

Die Making Machines

Sodick WEDM-LS machine

EDM Spark machine

CNC machine

Machinery | Quantity |

Grinding, Milling, Drilling machine | 8 |

CNC machine | 9 |

Fast speed wire cutting machine | 4 |

Middle speed wire cutting machine | 4 |

Low speed wire cutting machine | 3 |

Machinery | Quantity |

800T Press machine | 1 |

400T Press machine | 2 |

200-250T Press machine | 4 |

110T Press machine | 7 |

45-80T Press machine | 3 |

630T Hydraulic machine | 1 |

315T Hydraulic machine | 4 |

200T Hydraulic machine | 1 |

Feeding machine | Quantity |

GO-600F Max material width 600mm Max material thickness 2.5mm | 3 |

NCBF-600 Max material width 600mm Max material thickness 4.5mm | 1 |

NCMF-700 Max material width 700mm Max material thickness 3.2mm | 1 |

LN4-800 Max material width 800mm Max material thickness 6.0mm | 1 |

Quality Inspection

In order to ensure that each stamping die is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping die as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Packing & Delivery

To guarantee the delivery of stamping dies or molds

With rich experience in exporting, we choose reasonable packaging for you to reduce the shipping risk.

For the packaging of stamping die, the stamping dies are vacuum packed in aluminum film bag first, fastened by metal packing tape, and then packed in wooden cases.

Of course, we can also make the packing following customers' requirement.

Of course, we can also make the packing following customers' requirement.

Our customer

Household appliances cooperation customers

Automotive die cooperation customers

Contact US

If you want to get more information about Hiparter or progressive stamping die and progressive metal stamping die, please feel free to contact us as above.

Email: hpd@hiparter.com

l feedback to you within 24 hours.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices