Factory Customized High Precision Tool Washing Machine Plastic Motor Flange Injection Mold Vehicle Mold on Sale

- Category: >>>

- Supplier: Qingdao Hiparter Metal & Plastic Products Co. Ltd.Qingdao Ltd.

Share on (1601356046129):

Product Overview

Description

Products Description

Hiparter has more than 20 years experiences in designing and manufacturing plastic motor flange injection mold. We have developed a full-range universal plastic motor flange injection mold supply. Such as AC induction motor flange, Speed Variator Motor Flange, Servo Motor Flange and Motor Reducer Flange etc.

At the same time we are also proficient in motor flange stamping die manufacturing.

At the same time we are also proficient in motor flange stamping die manufacturing.

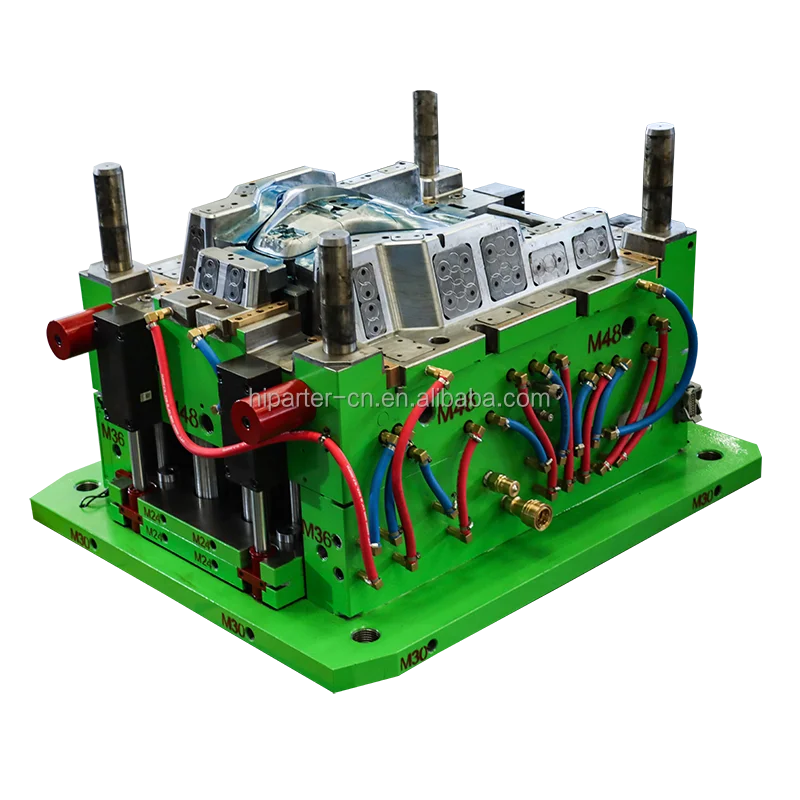

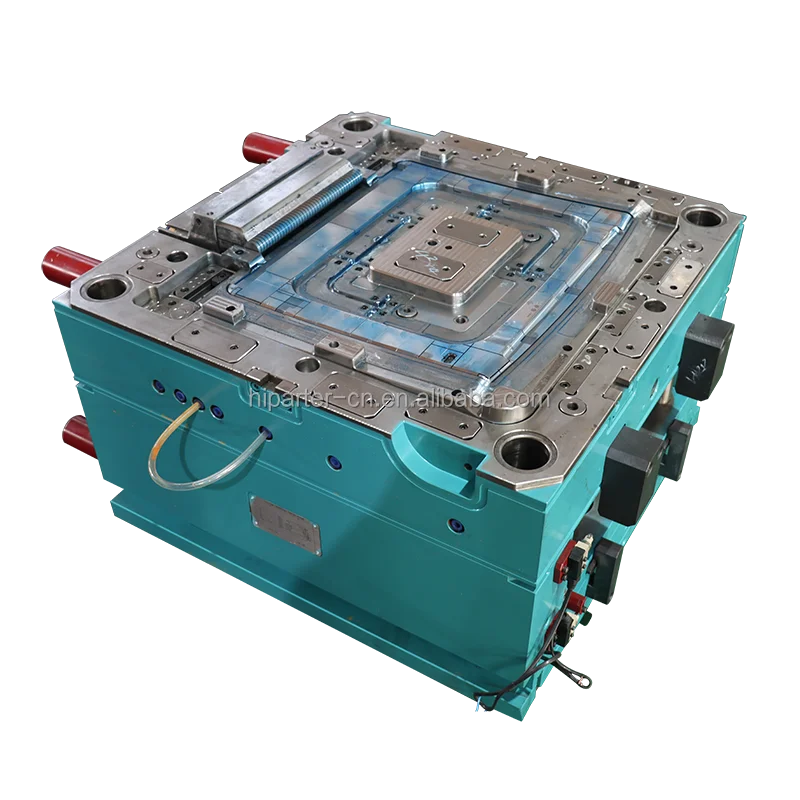

Plastic Motor Flange Injection Mold

Plastic Motor Flange

Motor Flange Plastic Injection Mold

Product Data | ||

Item: | Factory Customized High Precision Tool Washing Machine Plastic Motor Flange Injection Mold Vehicle Mold on Sale | |

Mold material: | 2738, NAK80, 718, 738H, 2344, S136, SKD61, P20 etc. | |

Cavity: | 1*1, 1*2 or others | |

Mold base: | LKM, HASCO etc. | |

Plastic product material: | POM, ASA, PP, ABS, PC, ABS+PC, PA, HIPS, PVC, PE, PS, Acrylic, etc. | |

Production process: | Injection molding | |

1) According to customers' drawings | ||

2) According to customers' samples | ||

1 year or 100 thousand shots(in this period, if the mold have any problem, we will offer the parts or service by free, but it doesn't include the problems caused by wrong operation) | ||

Mould precision: | +/-0.01mm | |

Ejection system: | Motor/hydraulic cylinder/stripping plate/angle pin, etc.... | |

Cooling system: | Water cooling or Beryllium bronze cooling, etc. | |

what we can offer

· Provide a original factory price

· Original product design of injection parts

· Original product design of injection parts

· Redesigned to offer a lower prices

· Supreme level of service and high quality

· Equipped with advanced CAD/CAM/CA

· Clear product standards

Customize Materials

Customize Shape

Molds Display

Our Advantages

Plastic Injection Mold

Design Capacity

1、We adhere to total solution service:

product design optimization→ mold design→ mold manufacturing →mold debugging→ product inspection→ die specification manual sharing→ after-sales support.

2、3D and CAD/CAM/CAE design.

3、More than 10 mold design engineers.

4、During nearly 20 years of development, Hiparter insists on providing high-standard and high-quality injection mold and support.

Plastic Injection Mold

Manufacturing Capacity

1、Injection mold machining equipment more than 28 sets.

2、Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets.

3、Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4、Almost all the machining process completed in-house.

5、We can guarantee the quality and lead time.

Plastic Injection Mold

Delivery Control Capacity

1、2~6 weeks lead time.

2、Update injection mold building progress to customer weekly, control project progress to ensure project schedule.

3、Exported to over 30 counties.

4、With more than 20 years of import and export experience, cooperate with powerful logistics companies and major express

companies, to ensure smooth export and delivered to customers asap.

companies, to ensure smooth export and delivered to customers asap.

Mold Making Machines

Sodick WEDM-LS machine

EDM Spark machine

CNC machine

Machinery | Quantity |

Grinding, Milling, Drilling machine | 8 |

CNC machine | 9 |

Fast speed wire cutting machine | 4 |

Middle speed wire cutting machine | 4 |

Low speed wire cutting machine | 3 |

Quality Inspection

FAQ

Q: What are the pros and cons of injection molding?

A:1.lt allows for complex geometries with tight tolerances.

2. It's compatible with a wide range of materials and colors.

3. lt's very efficient.

4. It offers high repeatability and reliability.

5. You can reuse material.

6. Start-up costs are high.

7.initial lead times are long.

Q:ls injection molding cheap or expensive?

A: The start-up costs for a large run can be expensive, but the price for the project becomes better and better as you continue to produce. lf you're looking at price per unit, plastic injection molding is one of the cheapest, most cost-efficient forms of manufacturing.

Q:ls injection molding faster than 3D printing?

A: Injection molding is ideal for high-volume production and for projects with longer turnaround times. Although it can be used with parts of various sizes, injection molding offers less design freedom. 3D is better for low-volume production runs, designs with frequent changes, and projects with quick turnaround times.

Q: How effective is injection molding?

A: Efficient high production. Once you have developed the molds, the process is extremely fast with cycle times as short as 10 seconds. lt is excellent for medium and high-volume production runs for anything from 10,000 parts to well over 100,000depending on what molds you use.

A:1.lt allows for complex geometries with tight tolerances.

2. It's compatible with a wide range of materials and colors.

3. lt's very efficient.

4. It offers high repeatability and reliability.

5. You can reuse material.

6. Start-up costs are high.

7.initial lead times are long.

Q:ls injection molding cheap or expensive?

A: The start-up costs for a large run can be expensive, but the price for the project becomes better and better as you continue to produce. lf you're looking at price per unit, plastic injection molding is one of the cheapest, most cost-efficient forms of manufacturing.

Q:ls injection molding faster than 3D printing?

A: Injection molding is ideal for high-volume production and for projects with longer turnaround times. Although it can be used with parts of various sizes, injection molding offers less design freedom. 3D is better for low-volume production runs, designs with frequent changes, and projects with quick turnaround times.

Q: How effective is injection molding?

A: Efficient high production. Once you have developed the molds, the process is extremely fast with cycle times as short as 10 seconds. lt is excellent for medium and high-volume production runs for anything from 10,000 parts to well over 100,000depending on what molds you use.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices