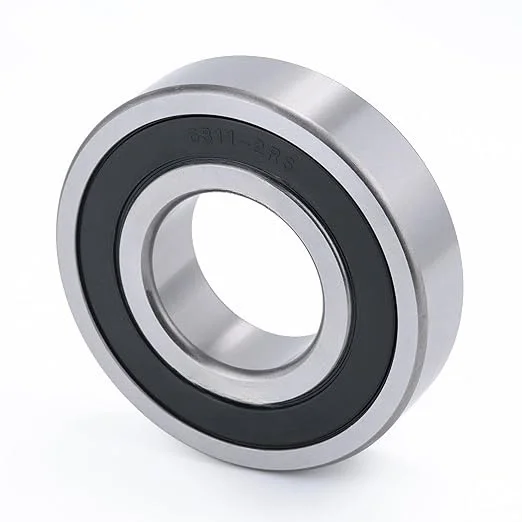

10*26*8 6000 2RS1 P0 2RS Chrome Steel All Seal Price Deep Groove Ball Bearing

- Category: >>>

- Supplier: Wuxi Kenbeta Precision Technology Co. Ltd.Wuxi Ltd.

Share on (1601356957416):

Product Overview

Description

Details Images

Basic Type

The single-row deep groove ball bearing can bear the radial and axial loads and allows a very high rotation speed. The deep groove ball bearing is non-detachable.\\nThe sealed deep groove ball bearing is free of maintenance, and can simplify the structure. These characteristics and its low price enable it to be the bearing with the widest application. However, the self-aligning ability of deep groove ball bearing is limited.

The basic types of deep groove ball bearing are the open type, double-face with sealing ring type, or double-face with dust cap type. As needed in the production, the bearing with sealing has the groove on the outer ring, where the sealing ring or dust cap may be mounted, or it may also be supplied as the open bearing.

Products Description

Structure | Composed of an inner ring, outer ring, rolling elements (balls), and a cage. |

Load Capacity | Can support both radial loads and axial loads. Especially efficient for radial loads. |

Noise and Friction | Low friction, smooth operation, and quiet performance, making it ideal for high-speed applications. |

Durability | Long service life when properly sealed or lubricated. |

Sealing Options | Available in sealed or shielded versions to prevent contamination and maintain lubrication. |

Common Materials | Typically made from high-carbon steel, ceramic, or stainless steel for improved performance and longevity. |

Types | - Single-row deep groove ball bearings (most common) |

- Double-row deep groove ball bearings | |

Speed Range | Suitable for both low-speed and high-speed applications, depending on the design. |

Applications | - Electric motors (most common) |

- Automotive (wheel hubs, drive shafts) | |

- Home appliances | |

- Industrial machinery (conveyors, pumps) | |

Lubrication | Requires regular lubrication (oil or grease) to reduce friction and wear. |

Maintenance | Regular inspection of seals and lubrication is essential to maintain performance. |

Advantages | - Simple structure |

- Cost-effective | |

- Versatile and widely used | |

- Easy to install and maintain | |

Temperature Range | Available in high-temperature versions for specific industrial applications. |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices