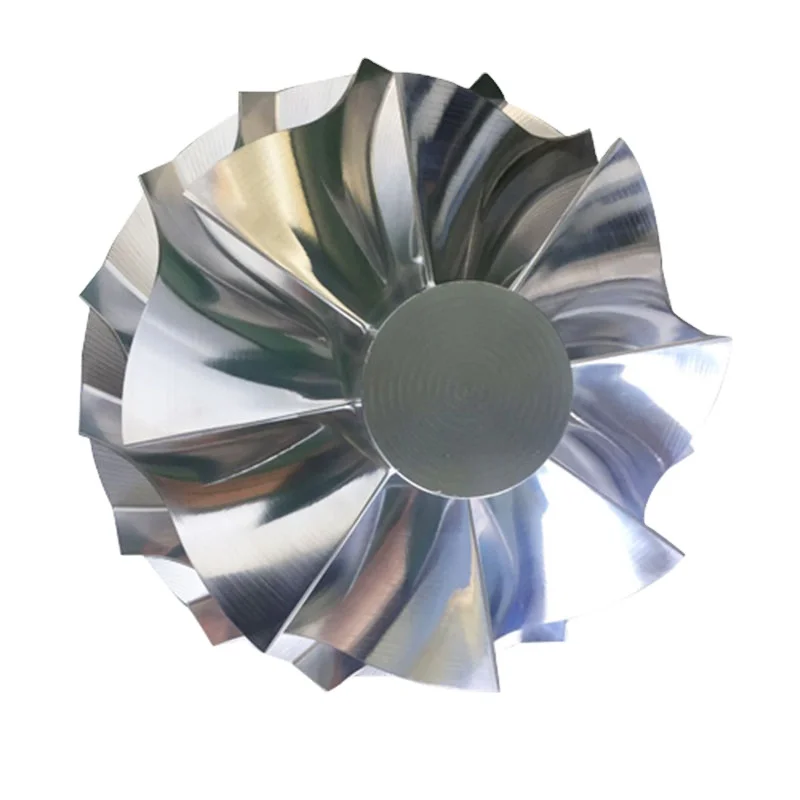

The TMS 162 gas turbine rotor blade leading edge protection arc section can improve erosion resistance and service life.

- Category: >>>

- Supplier: Shenzhen Yinghui Technology Co. Ltd.Shenzhen Ltd.

Share on (1601358785022):

Product Overview

Description

Specification

Product Name | Segment |

Tolerance | CNC Machining ±0.004mm/Casting ±0.1mm |

Place of Origin | shenzhen,guangdong,China |

Processing Craft | Sand Casting/Lost Wax Casting/Investment Casting/Vacuum Casting/Forging/CNC Machining/etc |

Surface Treatment | A variety of surface treatments and coatings can be produced and customized according to your requirements. |

Type | OEM; Customized |

Certification | ISO9001:2015 Certified, UL Certification,GE,SGS,TUV,etc |

Packing | Carton/Wooden box |

Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance. |

2.Third Party inspection available upon requirement. | |

3.Optional X-ray detection | |

4.Fluorescence detection | |

Service | Drawing Custom |

Mainly Testing Facility | Spectrometer,CMM, Tensile testing machine, Impact tester,Hardness tester,X-Ray,Salt spray test box, Pneumatic detection,UV accelerated weathering tester,dynamic balancing, high-temperature tensile testing,fluorescence test,room temperature mechanical property testing and other testing. |

Quality Guarantee | 2 Years |

Features & Advantage | 1.High machining accuracy, the flatness within 0.001mm |

2.High finish appearance, smooth surface roughness is Ra0.6 after machining. | |

3.The machining precision is high and the assembly structure is seamless. | |

4.Smooth appearance, corrosion resistance. | |

5.Pass Salt Spray Test with 144 Hours. | |

Standard | ISO , DIN, AISI, ASTM, BS, JIS, etc. |

GB/T 14992 GJB 5512.1 HB 7763 HB/Z 140 | |

Payment | L/C,D/A,D/P,T/T,Western Union,Money Gram |

Name | Inner Cavity Cooling Channel Coating | External Surface Coating |

Nickel Aluminum Diffusion Coating | MTK-NAI | MTK-WAI |

Aluminum Silicon Diffusion Coating | MTK-NAISi | MTK-JAISi |

Chrome Aluminum Diffusion Coating | MTK-NAICr | MTK-WAICr |

Diamond Aluminum Diffusion Coating | MTK-NAICo | MTK-WAICo |

Platinum Aluminum Diffusion Coating | MTK-WPtAl | |

Aluminum Diffusion Coating | MTK-NAITi | MTK-WAITi |

Q Salt Electroplating Platinum | MTK-WPt | |

Compressor Inorganic Phosphate Coating | MTK-WAI | |

MCrAIY Coating Technology | MTK-RZ | |

TBC | MTK-TBC | |

CVD Vapor Phase Aluminizing | ||

Chromated Aluminum Coating Technology |

FAQ

1.Q:What types and specifications of segment do you provide?

A: We offer several types ofsegment for different models and brands of fluid machinery, including but not limited to turbines,compressors and pumps. Our segment are available in both fixed and adjustable types to suit different operating conditions and performance requirements. Please refer to our catalogue for specific specifications and models or contact our sales team, we will provide details according to your specific needs and ensure that we provide you with the best segment ring for your equipment.

2.Q: What materials are used to make yoursegment? How is the quality guaranteed?

A: Our segment rings are made of high quality stainless steel, nickel base alloy, cobalt base alloy and other high temperatu reresistant, high strength materials. These materials are able to withstand extreme working conditions and ensure long-term stable operation. All materials are subject to strict quality control and testing, in line with international standards. We have passed quality certifications such as ISO 9001 to ensure the quality and consistency of our products. In addition, every product is rigorously tested before leaving the factory to ensure its performance and reliability.

3.Q: Do you offer customized segment rings? What is the customization process?

A: Yes, we offer customized segmented ring services. You can provide us with specific technical parameters and design

requirements, and our team of engineers will work closely with you to support you from design to production. The customization process includes initial consultation, design confirmation, prototyping, final production and delivery. We will ensure that every step is in line with your expectations and provide a detailed project progress report. Customized services are designed to meet your specific application needs, ensuring optimal performance and compatibility.

4.Q: What kind of after-sales service and technical support do you provide after purchasing the segment ring?

A: We provide comprehensive after-sales service and technical support, including 24-hour responsive customer service. If you encounter any problems during use, our technical team will be ready to provide you with technical support and solutions. In addition, we also provide a warranty service to ensure a worry-free experience during use. Our goal is to ensure that your equipment is always in top working condition, resulting in increased efficiency and longer service life.

5.Q: What's your delivery time and shipping method?

A: Delivery times are usually 4-6 weeks for standard products, and may vary for custom products, depending on design complexity and production arrangements. We will provide accurate delivery times according to your requirements. Transport can be by sea, air or land, depending on your geographical location and the degree of urgency. We work with a number of international logistics companies to ensure that your products are delivered safely and on time. If you have any special needs, please inform us in advance and we will try our best to meet your requirements.

A: We offer several types ofsegment for different models and brands of fluid machinery, including but not limited to turbines,compressors and pumps. Our segment are available in both fixed and adjustable types to suit different operating conditions and performance requirements. Please refer to our catalogue for specific specifications and models or contact our sales team, we will provide details according to your specific needs and ensure that we provide you with the best segment ring for your equipment.

2.Q: What materials are used to make yoursegment? How is the quality guaranteed?

A: Our segment rings are made of high quality stainless steel, nickel base alloy, cobalt base alloy and other high temperatu reresistant, high strength materials. These materials are able to withstand extreme working conditions and ensure long-term stable operation. All materials are subject to strict quality control and testing, in line with international standards. We have passed quality certifications such as ISO 9001 to ensure the quality and consistency of our products. In addition, every product is rigorously tested before leaving the factory to ensure its performance and reliability.

3.Q: Do you offer customized segment rings? What is the customization process?

A: Yes, we offer customized segmented ring services. You can provide us with specific technical parameters and design

requirements, and our team of engineers will work closely with you to support you from design to production. The customization process includes initial consultation, design confirmation, prototyping, final production and delivery. We will ensure that every step is in line with your expectations and provide a detailed project progress report. Customized services are designed to meet your specific application needs, ensuring optimal performance and compatibility.

4.Q: What kind of after-sales service and technical support do you provide after purchasing the segment ring?

A: We provide comprehensive after-sales service and technical support, including 24-hour responsive customer service. If you encounter any problems during use, our technical team will be ready to provide you with technical support and solutions. In addition, we also provide a warranty service to ensure a worry-free experience during use. Our goal is to ensure that your equipment is always in top working condition, resulting in increased efficiency and longer service life.

5.Q: What's your delivery time and shipping method?

A: Delivery times are usually 4-6 weeks for standard products, and may vary for custom products, depending on design complexity and production arrangements. We will provide accurate delivery times according to your requirements. Transport can be by sea, air or land, depending on your geographical location and the degree of urgency. We work with a number of international logistics companies to ensure that your products are delivered safely and on time. If you have any special needs, please inform us in advance and we will try our best to meet your requirements.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices