Welding Positioner Rotating and Turning Table

- Category: >>>

- Supplier: Shandong Ouka Intelligent Equipment Co. Ltd.Shandong Ltd.

Share on (1601361479075):

Product Overview

Description

Product Overview

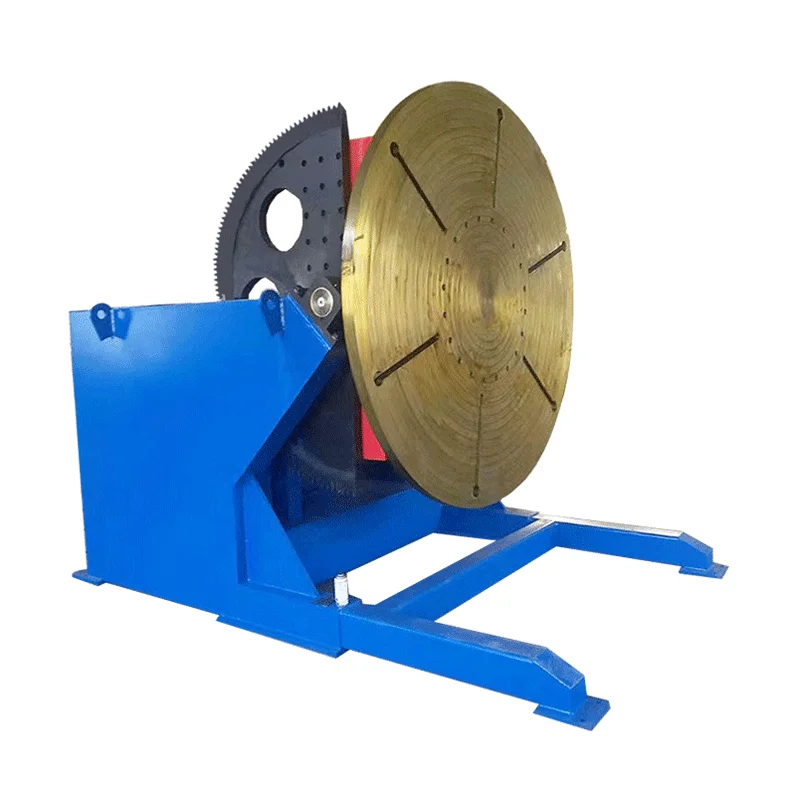

Seat Type Welding Positioner

Scope of Application:Applied to a variety of welding shaft, disk, cylinder of the rotating body of the workpiece.

Brief Intro:Through the rotation and flipping of the worktable, the workpiece is in the optimal welding or assembly position.

Details Images

Features:

1. Variable frequency stepless speed regulation.

2. Can turning freely.

3. Wide applicability.

4. The work surface is made by precision machining of castings, which is not easy to be damaged by welding spatter.

5. The body adopts a seat structure, and the overall stability of the equipment is good.

1. Variable frequency stepless speed regulation.

2. Can turning freely.

3. Wide applicability.

4. The work surface is made by precision machining of castings, which is not easy to be damaged by welding spatter.

5. The body adopts a seat structure, and the overall stability of the equipment is good.

PRODUCT SPECIFICATIONS

The welding positioner is a practical auxiliary positioner. It is mainly used in workplaces such as welding of steel structures and assembly of mechanical parts. It is widely used in the manufacturing industry of various steel structures such as flanges, pipe joints, etc. It can also be used as peripheral equipment and a robot to achieve automatic welding. It is one of the commonly used equipment in modern pipeline, container, and steel structure manufacturing enterprises.

The seat-type positioner is composed of a rotating mechanism, a turning mechanism, a frame, and an electronic control system. It rotates and flips the worktable to make the workpiece in the optimal welding or assembly position. The rotation of the worktable adopts stepless speed regulation by frequency conversion. The worktable is driven to tilt by sector gear or hydraulic cylinder.The rotation angle of the worktable is 0 ~ 120 °. It can realize joint control with an operation machine or welding machine. The control system can be configured with three types of configurations: push-button digital control, switch digital control, and switch relay control.

The seat positioner can be used with various automatic welding or manual welding, can be used for pipe and pipe butts welding, pipe end welding, and various shafts, disks, cylinders, and other workpieces. It has a compact structure, beautiful appearance,and convenient operation. Etc. The seat positioner is currently the most widely used structural form. In production, it can not only improve the welding quality, but also reduce the number of work transfers, reduce labor intensity, and quickly improve production efficiency.

The seat-type positioner is composed of a rotating mechanism, a turning mechanism, a frame, and an electronic control system. It rotates and flips the worktable to make the workpiece in the optimal welding or assembly position. The rotation of the worktable adopts stepless speed regulation by frequency conversion. The worktable is driven to tilt by sector gear or hydraulic cylinder.The rotation angle of the worktable is 0 ~ 120 °. It can realize joint control with an operation machine or welding machine. The control system can be configured with three types of configurations: push-button digital control, switch digital control, and switch relay control.

The seat positioner can be used with various automatic welding or manual welding, can be used for pipe and pipe butts welding, pipe end welding, and various shafts, disks, cylinders, and other workpieces. It has a compact structure, beautiful appearance,and convenient operation. Etc. The seat positioner is currently the most widely used structural form. In production, it can not only improve the welding quality, but also reduce the number of work transfers, reduce labor intensity, and quickly improve production efficiency.

Model No. | BW2-1T | BW2-2T | BW2-3T | BW2-5T | BW2-10T | BW2-15T | BW2-20T | ||||||

Basic loading (kg) | 1200 | 2000 | 3000 | 5000 | 10000 | 15000 | 20000 | ||||||

Rotating speed(r/min) | 0.1~1 | 0.1~1 | 0.06~0.6 | 0.05~0.5 | 0.05~0.5 | 0.02~0.2 | 0.02~0.2 | ||||||

Overturning speed(r/min) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.15 | 0.2 | ||||||

Turning angle(°) | 120 | ||||||||||||

Work table diameter(mm) | 1000 | 1100 | 1400 | 1600 | 2000 | 2200 | 2500 | ||||||

Height of work table(mm) | 1100 | 1200 | 1500 | 1550 | 1900 | 2000 | 2100 | ||||||

Allow work piece off-center(mm) Eccentricity | 150 | 150 | 200 | 200 | 200 | 200 | 200 | ||||||

Allow work piece off-center(mm) Centroidal distance | 250 | 250 | 300 | 300 | 400 | 500 | 600 | ||||||

Rotating motor power(kw) | 0.75 | 1.5 | 1.5 | 2.2 | 3 | 4 | 5.5 | ||||||

Turning mootr power(kw) | 0.75 | 1.5 | 1.5 | 3 | 4 | 5.5 | 7.5 | ||||||

Recommend Products

Company Profile

Since established, Shandong Ouka Intelligent Equipment Co., Ltd.. has focused on introducing and cultivating high-tech talents and takes it as development strategy at present, many professionals have been brought together who specialize in researching and developing of CNC welding and cutting equipment. technical strength is always cherished as core competitiveness of our company.

With constant efforts of all staffs, our products have been sold well in domestic market and exported to many countries in the world. During establishing the national brand of Ouka, we always hold the responsibility of culture communication between china and the world.

With constant efforts of all staffs, our products have been sold well in domestic market and exported to many countries in the world. During establishing the national brand of Ouka, we always hold the responsibility of culture communication between china and the world.

Product packaging

FAQ

1.When the machine can’t work well, What should I do?

(1)Engineer is online for 24-hours, they can check the problems and then give you solutions in two hours.

(2)our machine is with one’s year warranty, If any problems of machine parts under “normal use”, new machine parts will be sent by air In free.

(3)Please rest assured that operation CD and manual will be offered along with the machine, making you can operate the machine easily. Professional engineering and technical personnel. We will provide you with reasonable and valuable Suggestions andsolutions according to your requirements, the engineering feasibility and economic benefit, etc.

Provide knowledge of equipment operation and maintenance, Allows you to accurately grasp the characteristics of the machine. one year warranty, life-long maintenance services through email or telephone. Please feel free to use it. Supply all kinds of accessories and replacements.

2. Does your company accept the customized offer, we have a special need.

(2)our machine is with one’s year warranty, If any problems of machine parts under “normal use”, new machine parts will be sent by air In free.

(3)Please rest assured that operation CD and manual will be offered along with the machine, making you can operate the machine easily. Professional engineering and technical personnel. We will provide you with reasonable and valuable Suggestions andsolutions according to your requirements, the engineering feasibility and economic benefit, etc.

Provide knowledge of equipment operation and maintenance, Allows you to accurately grasp the characteristics of the machine. one year warranty, life-long maintenance services through email or telephone. Please feel free to use it. Supply all kinds of accessories and replacements.

2. Does your company accept the customized offer, we have a special need.

Ouka CNC is a company that focuses on research and manufacture of modular CNC machines. We have very rich experience and strong machine tool research and development capability. We are very willing to offer you customized highly-efficient equipment as long

as you have a certain amount of needs.

3. What certificate the machine in your company get?

We’ve passed the ISO9001 Quality System Approval and CE Certification.

4. Does your company accept CIF price?

CIF price includes the shipping cost of the CNC machine which needs to quote according to the different destination port and various in different months. Please contact us when you have such a need. CIF price also includes marine premium which is 2‰ of 1.1*total amount.

5. What are your methods of transportation?

For most countries, we will transport our machine by sea, as for inland countries, we may use railway or highway transportation. The exported CNC machine is all be packed by a wooden case which can be fixed into a 40 HQ.

6.If the machine is out-of-warranty, how to charge the cost of accessories?

For the out of warranty machine which needs to replacement parts, we will charge according to the parts quotation. If you have any questions, please email us for consultation.

7. Does MC have a maintenance manual and operation manual?

Each CNC machine leaving the factory will be along with a related series or model the English instructions including maintenance manual and operation manual. Attached documentation may also include CNC controller instruction, parts instruction you bought(like

a rotary table, oil cooler).

as you have a certain amount of needs.

3. What certificate the machine in your company get?

We’ve passed the ISO9001 Quality System Approval and CE Certification.

4. Does your company accept CIF price?

CIF price includes the shipping cost of the CNC machine which needs to quote according to the different destination port and various in different months. Please contact us when you have such a need. CIF price also includes marine premium which is 2‰ of 1.1*total amount.

5. What are your methods of transportation?

For most countries, we will transport our machine by sea, as for inland countries, we may use railway or highway transportation. The exported CNC machine is all be packed by a wooden case which can be fixed into a 40 HQ.

6.If the machine is out-of-warranty, how to charge the cost of accessories?

For the out of warranty machine which needs to replacement parts, we will charge according to the parts quotation. If you have any questions, please email us for consultation.

7. Does MC have a maintenance manual and operation manual?

Each CNC machine leaving the factory will be along with a related series or model the English instructions including maintenance manual and operation manual. Attached documentation may also include CNC controller instruction, parts instruction you bought(like

a rotary table, oil cooler).

We Recommend

Professional Solution for Batch Welding: 2-axis Pipe Welding Positioner

$1,400.00-1,600.00

30 kg Aluminum Pipe Welding Positioner With 3 Jaw Quick Chuck

$950.00-1,100.00

New Arrivals

New products from manufacturers at wholesale prices