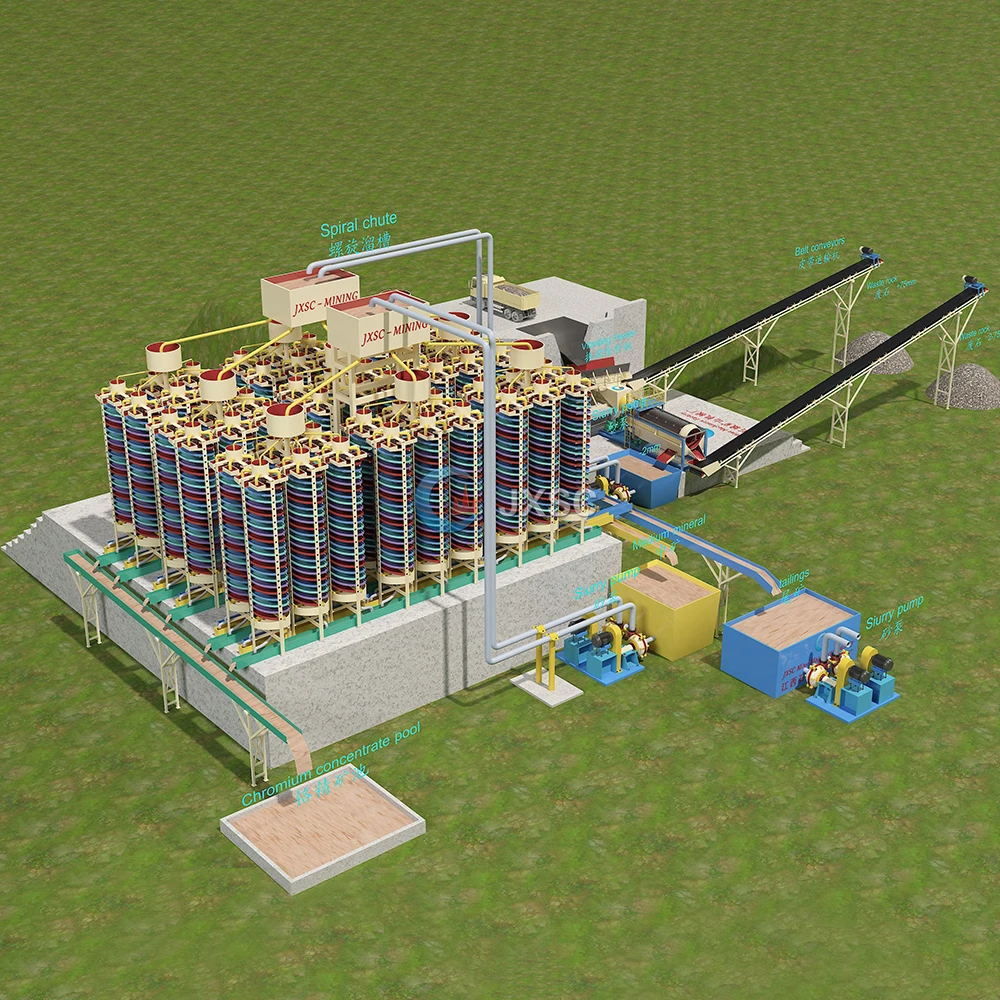

JXSC 100tph 120tph Complete Rock Chrome Chromite Ore Washing Plant

- Category: >>>

- Supplier: Jiangxi Province County Mining Machinery FactoryJiangxi Factory

Share on (1601361815162):

Product Overview

Description

2. Cleaning system: Cleaning is a key step in removing clay and mud from the raw ore. Two main types of equipment are used:

Trommel scrubber: suitable for raw ore containing a large amount of sticky clay.

Trommel screen: suitable for raw ore with less sticky clay content.

This step can also perform preliminary particle size classification.

3. Screening system: The cleaned ore enters the screening stage, and the following equipment is mainly used:

Vibrating screen: suitable for screening a larger particle size range.

High frequency screen: widely used in chromium ore beneficiation, especially suitable for screening fine-grained minerals.

The slurry under the screen enters the subsequent sorting equipment, and the large waste rock on the screen is discharged.

Jig separator : Use the difference in specific gravity of minerals for separation, suitable for processing coarse-grained ores.

Spiral chute: Use centrifugal force and gravity to separate minerals, suitable for medium and fine-grained ores.

The concentrate products of these equipment will enter the secondary gravity separation.

5. Secondary gravity separation:

Use a shaking table for concentration. The shaking table is one of the most effective gravity separation equipment in chromium ore beneficiation, and can obtain higher-grade concentrate products. It can handle fine-grained minerals and has high separation accuracy.

6. Magnetic separation to improve grade: Finally, a magnetic separator is used to improve the concentrate. Although chromium ore is mainly non-magnetic, magnetic separation can remove some magnetic impurities (such as magnetite) to further improve the concentrate grade.

After the above process, a high-grade chromium ore concentrate product can be obtained.

The feeding method, primary selection, final concentration and chrome ore refining process of rock chrome ore processing plant are basically the same as those of alluvial/sand chromite processing plant mentioned above.

However, rock chrome ore processing plant also needs crushing and grinding before primary selection:

Crushing: It is used to break large pieces of rock chrome ore into smaller sizes before grinding.

Commonly used jaw crushers, hammer crushers, cone crushers, and roller crushers depend on the feed size and processing capacity of the rock chrome ore.

Grinding: Grinding is to fully release the chromium in the ore and meet the feeding requirements of the gravity separation equipment. Ball mill is the most commonly used grinding equipment, suitable for wet or dry grinding.

3. The material will be fed into hammer crusher by belt conveyor, using hammer crusher for crushing the big slag into fine

particles 3mm.

4. The output size can be adjusted based on your requirement. 5. The output from the hammer crusher goes to the jig separator for catching concentrates first.

Different mine situations and different requirements, the solution will be different.

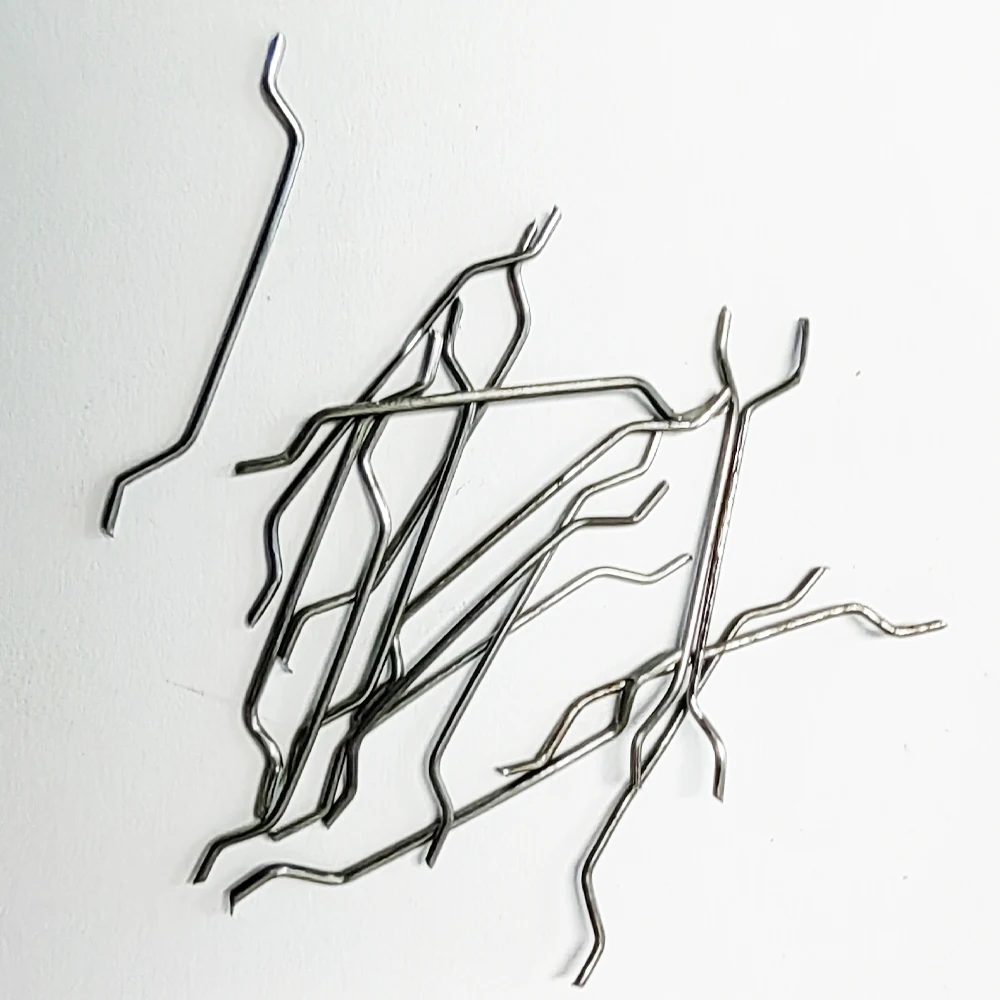

1.Small parts packed in the wooden cases |

2.Big parts packed by plastic membrane |

3.The whole big machine is loaded in the container |

experiences,providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore /Diamond/ Coltan ore /Silica sand /Zircon sand/ Black sand/Chrome ore/Cobalt ore/Antimony ore, ect. As well as complete set small laboratory mining machines.

manufacturer equipment according to your special demand.

●Pre-sales service: We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

●Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

●After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How is the quality of your products?

●How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

●How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices