10 Micron Sintered SS Metal Fiber Pleated Fuel Gas Filter element for Natural Gas and Other Petrochemical Gas

- Category: >>>

- Supplier: Hebei Lianda Filter Equipment Co. Ltd.Hebei Ltd.

Share on (1601366458249):

Product Overview

Description

Products Description

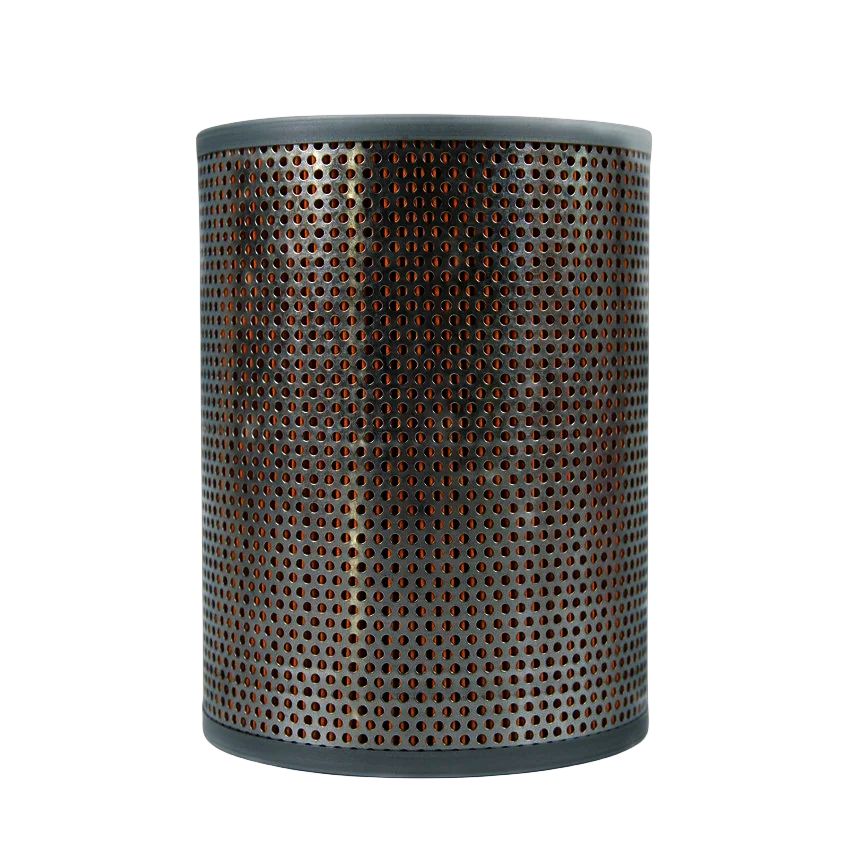

Model | PF100/500-10 | Nominal rating(μm) | 10 micron | ||

Classification | Stainless steel pleated filter cartridge | Outer diameter(mm) | 100 | ||

Filter media | Pleated / corrugated wire mesh sintered metal fiber fleece | Length(mm) | 500 | ||

Material | 316L stainless steel | Connector / End fitting | SOE glued cap | ||

Application | Fuel gas filter for natural gas and other petrochemical gas | ||||

*Customized product can be produced once negotiated.

*Other material including 304, 310, 904L, Duplex, Inconel, Hastelloy and Monel also available for custom needs.

*Other material including 304, 310, 904L, Duplex, Inconel, Hastelloy and Monel also available for custom needs.

*Bekaert sintered metal fiber fleece / felt is available as required

Fuel gas pleated filter element is made of pleated sintered metal fiber fleece protected with plain weave wire mesh. These stainless steel filter elements function as particle filter to filtrate the solids from the gas. While the gas passes through the pleated filter elements, the solid particles are captured and constrained by sinter metal fiber fleece. The differential pressure then increases as the particles gradually block the filter media pores. Filter elements can be cleaned by automatic backflushing or offline manual cleaning to restore the differential pressure.

Fuel gas pleated metal fiber filter cartridge is reinforced with perforated metal inside the pleats to ensure enough strength under working pressure and backflushing. Connector and the end cap is glued with the pleats for better sealing and light weight benefit. Welding for connector and end cap, extra support outside the pleats, pleated wire mesh without metal fiber fleece and other configuration are also available as required.

Fuel gas pleated metal fiber filter cartridge is reinforced with perforated metal inside the pleats to ensure enough strength under working pressure and backflushing. Connector and the end cap is glued with the pleats for better sealing and light weight benefit. Welding for connector and end cap, extra support outside the pleats, pleated wire mesh without metal fiber fleece and other configuration are also available as required.

Product Family:

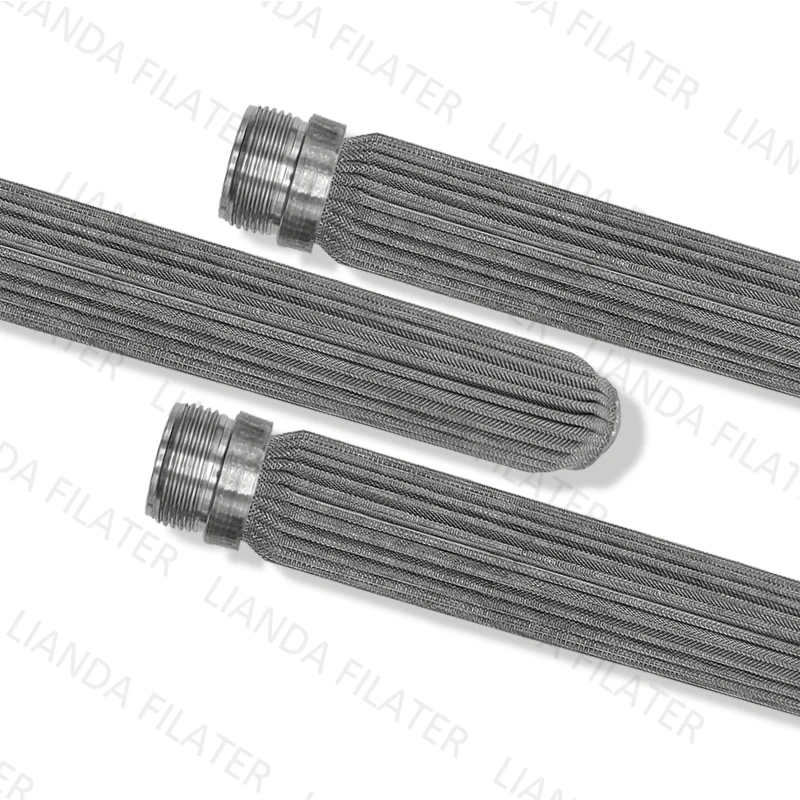

Pleated Wire Mesh

Pleated wire mesh is the filter media for the pleated filter element. Different layers of wire mesh or even sintered mesh and sintered metal fiber can be joined as a whole by the processing of pleating and then end welding.

These can be achieved by using pleated wire mesh media in a filter element, comparing to ordinary wire mesh.

- larger effective filtration area

- excellent dirty holding capacity

- robust constructure for better life span

These can be achieved by using pleated wire mesh media in a filter element, comparing to ordinary wire mesh.

- larger effective filtration area

- excellent dirty holding capacity

- robust constructure for better life span

Our Advantages

Sales:

* One to one service.

* Quick respond in 24 hours.

OEM and design:

* Fully customized from raw mesh to part number engraving, according to your drawing.

* Design and CAD ability to meet your specific requirement in various application.

Quality:

* Bubble point test and other laboratory test to ensure functionality.

* ISO9001 management system to maintain quality consistency.

* One to one service.

* Quick respond in 24 hours.

OEM and design:

* Fully customized from raw mesh to part number engraving, according to your drawing.

* Design and CAD ability to meet your specific requirement in various application.

Quality:

* Bubble point test and other laboratory test to ensure functionality.

* ISO9001 management system to maintain quality consistency.

Product packaging

Robust packaging for safe delivery.

Various delivery methods to meet customer's need.

Various delivery methods to meet customer's need.

Hot sale

Company Profile

Hebei Lianda Filter Equipment Co., Ltd. was founded in 1998. The company introduces foreign advanced production and testing equipment, production technology and technology, and adopts world-class quality filter materials as the main filter material, specializing in the production of porous metal sintered materials and filter elements. (Melt filter, sintered mesh filter, filter disc, filter and other industrial filters such as air filter, water filter, oil filter), filter and filter system assembly.

Products are widely used in petroleum, chemical, chemical fiber, aviation, aerospace, nuclear industry, pharmaceutical,

metallurgy, electric power, water treatment, food and beverage, coal chemical and other industries.

The company relies on Beijing Aerospace Power Research Institute, Sinopec Engineering Design Institute, Beijing Iron and Steel Research Institute and other research institutes to initially form a production situation from raw materials, finished products to filtration system assemblies. He has participated in supporting projects of national key projects such as aviation, aerospace, nuclear industry and petrochemical industry. In recent years, the company has continuously improved its internal management and established a sound quality management system to enable the company to maintain its leading position in product quality and service quality competition.

Products are widely used in petroleum, chemical, chemical fiber, aviation, aerospace, nuclear industry, pharmaceutical,

metallurgy, electric power, water treatment, food and beverage, coal chemical and other industries.

The company relies on Beijing Aerospace Power Research Institute, Sinopec Engineering Design Institute, Beijing Iron and Steel Research Institute and other research institutes to initially form a production situation from raw materials, finished products to filtration system assemblies. He has participated in supporting projects of national key projects such as aviation, aerospace, nuclear industry and petrochemical industry. In recent years, the company has continuously improved its internal management and established a sound quality management system to enable the company to maintain its leading position in product quality and service quality competition.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices