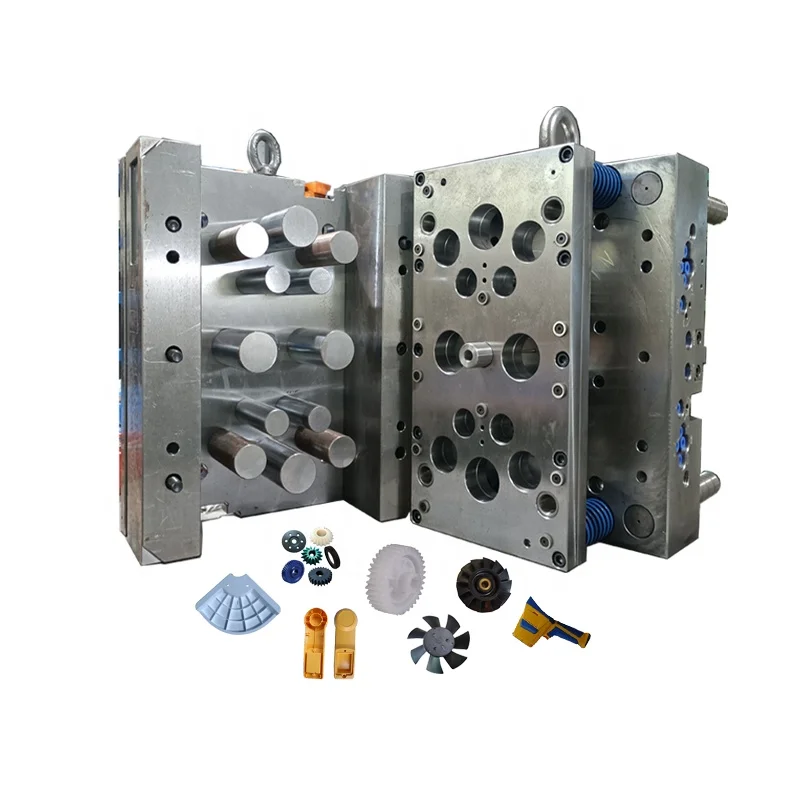

Paver Molds Shoes Mold Polyurethane Rotomolding Beton Form Blow Aluminum Concrete Wall Panel Thermoforming For Injection Molds

- Category: >>>

- Supplier: Dongguan Cents Precision Manufacturing Co. Ltd.Dongguan Ltd.

Share on (1601367823269):

Product Overview

Description

What We Do: | ||||||||

1). | We make Export Mold / Mould; Our Moulds have been exporting to UK, USA, Spain, Germany, Canada,Poland, Ukraine... | |||||||

2). | ||||||||

Information for Mold and Parts:

Mould Information | Product Name | Plastic Injection Mould | ||

Mould Standard | LKM/HASCO/FUTABA/DME according to buyer's requirement | |||

Mold Type | Injection Mould | |||

Sprue Gate | Pin-Point Gate, Submarince Gate... | |||

Mold Cavity | Single or multi cavity | |||

Runner Form | Cold Runner or hot runner according to product type and cavity | |||

Mould Material | NAK80, S136, 2344,2316, 718, P20... | |||

Mould life | 300000-800000shots | |||

Mould Maintenace | Keep it well maintened | |||

Plastic Part | Material | ABS, PP, PC, ABS+PC, PA66, PTFE, PEI... according to buyer's requirement | ||

Injection machine | 30ton, 100ton, 160ton, 450ton, 500 ton, 800ton... | |||

File Support | 3D drawing in Step, UG... | |||

Injection time | According to cavity, product constructure | |||

Injection system | Automatic ejection, Robert Jig system.. | |||

Custom Compression Mould Punching Mold Casting Mold Press Form Injection Mold

Company Profile

Our Main Features:

1). We Do the Whole Mould Making Processes in House to control better Cost,Delivery and Quality:

Grinding-Drilling-EDM-WEDM-CNC Machining-Polishing-Mould Testing...

Grinding-Drilling-EDM-WEDM-CNC Machining-Polishing-Mould Testing...

imd / iml parts Injection molding | |

overmould parts Injection molding | |

two colors parts Injection Molding |

Cents was certified with ISO9001 quality system by the International Standards Authority(ISA) in 2008.

All the employees took part in the training. The quality responsibility for each department was clarified, and the management procedure was specified.Besides,the coordination between the input and output was also defined. Quality manual and program files were compiled. In the future production process, we will insist on continuous improvement to the the key weak link.

Quality Control System

It`s a long process for each product from material purchasing to the final delivery. If an error can not be identified timely, the

delivery will get delay, and cause waste on human labor and material etc. To ensure customer get the qualify products,

Cents QC Procedure

1. Part mold draft analysis

2. Mold design control

3. Steel hardness inspection

4. Dimension inspection of electrode ,cavity and core

5. Mold trial report and inspection report

6. PPAP

7. Shipment inspection

Quality Control System

It`s a long process for each product from material purchasing to the final delivery. If an error can not be identified timely, the

delivery will get delay, and cause waste on human labor and material etc. To ensure customer get the qualify products,

Cents QC Procedure

1. Part mold draft analysis

2. Mold design control

3. Steel hardness inspection

4. Dimension inspection of electrode ,cavity and core

5. Mold trial report and inspection report

6. PPAP

7. Shipment inspection

Relative Products

We make all kinds of Customize Plastic Parts/Case/Enclosure

Mainly covering to:

1) Auto parts mold and molding ;

1) Auto parts mold and molding ;

2) Consumer Electronics Enclosures mold and molding;

3) Household Produts Case mold and molding;

4) Industrial Tool Parts mould and moulding;

5) Cosmetic Tube or Container mould and moulding...Etc

One of our big advantage is making the IMD / IML Injection mold molding parts

1. 3D file or Real Sample for your products; 2. Material you require; 3. Surface treatment requirement

So our above price is only for your reference. We can quote exact price according to:

1. 3D file or Real Sample for your products; 2. Material you require; 3. Surface treatment requirement

Our Customer

Stable and Double Win Cooperation Is the Goal We Have Been Pursuing.

If you have any new Custom Plastic Parts / Enclosure / Case / Frame to be developed,please feel free to:

i). Send us 3d drawing in stp,sign NDA is acceptable if necessary;

ii). Let us know what material to be used for the part;

iii). Better to tell us the yearly qty plan,so we could have better mold design suggestion to you.

i). Send us 3d drawing in stp,sign NDA is acceptable if necessary;

ii). Let us know what material to be used for the part;

iii). Better to tell us the yearly qty plan,so we could have better mold design suggestion to you.

Product packaging

i). If the mould should be exported to the buyer, then we will use Pallet , or multilayer wooden box;

ii). If the mould will be kept in our factory for injection molding, then the parts will use our factory's packing way.

FAQ

Fast Quotation is one of our big advantage

Q.How many molds will your factory make in a month?

A. Our capability is 120 sets-150 sets molds one month;

B. 300,000-3,000,000 pcs plastic injection parts basis on different products.

Q. What's your mold tolerance?

A. 0.005-0.02mm according to different product requirements.

Q. What I should offer to you if I need a quote?

A. 2D product drawing & 3D File, or send us real plastic sample.

Q. Which material will your factory use to make a mold?

A. Our regular material has NAK80, S136, LKM, DAIDO, HASCO, DME

Q. What's your delivery time for molds and plastic injection products?

A. Our delivery time for mold: 3-5 weeks as mold structure complexity. And our delivery time for plastic injection products: 3-18days.

Q. What we need to provide if we want to start cooperation?

A. 1. 3D file or Real sample for your products; 2. Material as you require; 3. Surface treatment requirement

A. Our capability is 120 sets-150 sets molds one month;

B. 300,000-3,000,000 pcs plastic injection parts basis on different products.

Q. What's your mold tolerance?

A. 0.005-0.02mm according to different product requirements.

Q. What I should offer to you if I need a quote?

A. 2D product drawing & 3D File, or send us real plastic sample.

Q. Which material will your factory use to make a mold?

A. Our regular material has NAK80, S136, LKM, DAIDO, HASCO, DME

Q. What's your delivery time for molds and plastic injection products?

A. Our delivery time for mold: 3-5 weeks as mold structure complexity. And our delivery time for plastic injection products: 3-18days.

Q. What we need to provide if we want to start cooperation?

A. 1. 3D file or Real sample for your products; 2. Material as you require; 3. Surface treatment requirement

We Recommend

New Arrivals

New products from manufacturers at wholesale prices