Low Viscosity Easy Flowing Resin Sand For Core Making Efficient Filling Ability

- Category: >>>

- Supplier: Gongyi City Tonten Abrasive Co. Ltd.Gongyi Ltd.

Share on (1601368035601):

Product Overview

Description

Products Description

Low Viscosity Easy Flowing Resin Sand For Core Making Efficient Filling Ability

Resin Sand

=======

Resin sand refers to molding sand or core sand with synthetic resin as the binder of sand particles. After the mold or core is made of resin sand, the resin is cured by irreversible cross-linking reaction through the action of solidifying (hardening) agent, so as to give the mold or core the necessary strength. Resin sand is widely used as mold (core) sand in modern casting production. The mold (core) sand with resin as binder mainly includes thermal coated resin sand, hot core box resin sand, cold core box resin sand, furan resin sand, furan resin self hardening sand, etc. Resin sand has high strength after hardening, which is especially suitable for machine modeling and can produce complex and thin-walled castings.

Specification Of Resin Sand

=========

Technical Indicators of Resin Sand | ||||

Project | Main Technical Indicators | |||

Type Ⅱ | Type Ⅲ | |||

Chlorine content % | Trace 1% | Trace 1% | ||

PH value | 4-8PH | 4-8PH | ||

Conductivity us/cm | 100us/cm | 100us/cm | ||

Water absorption % | 10.0% | 10.0% | ||

Bulk density g/cm3 | 0.6-0.7 g/cm3 | 0.6-0.7 g/cm3 | ||

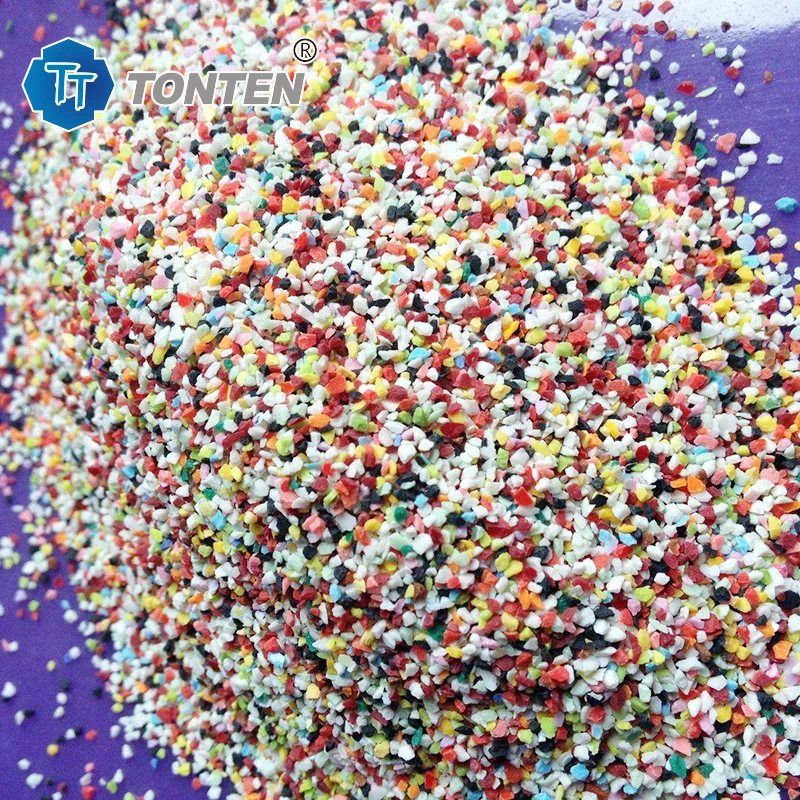

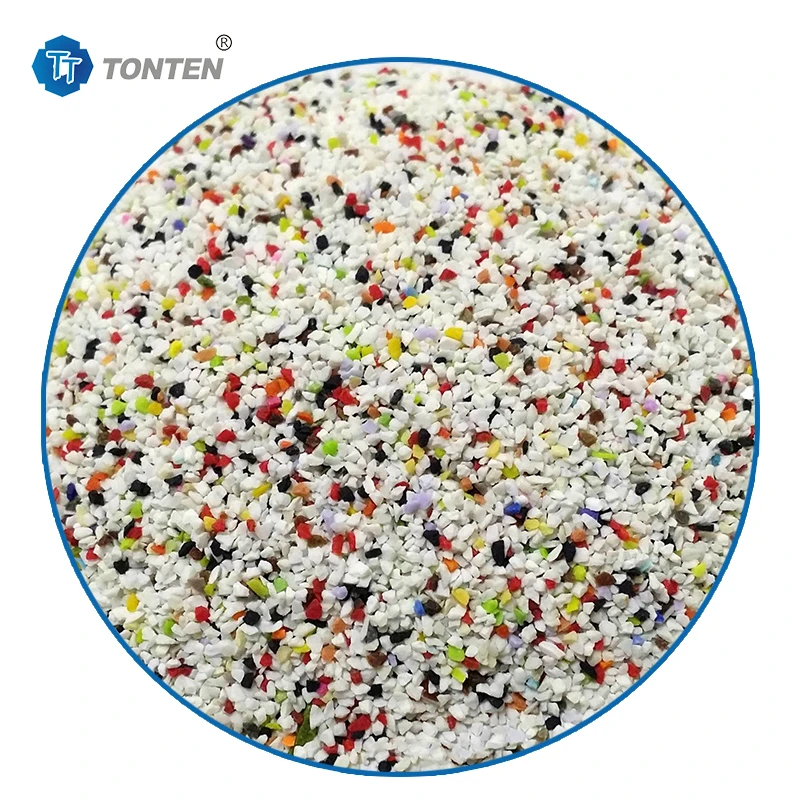

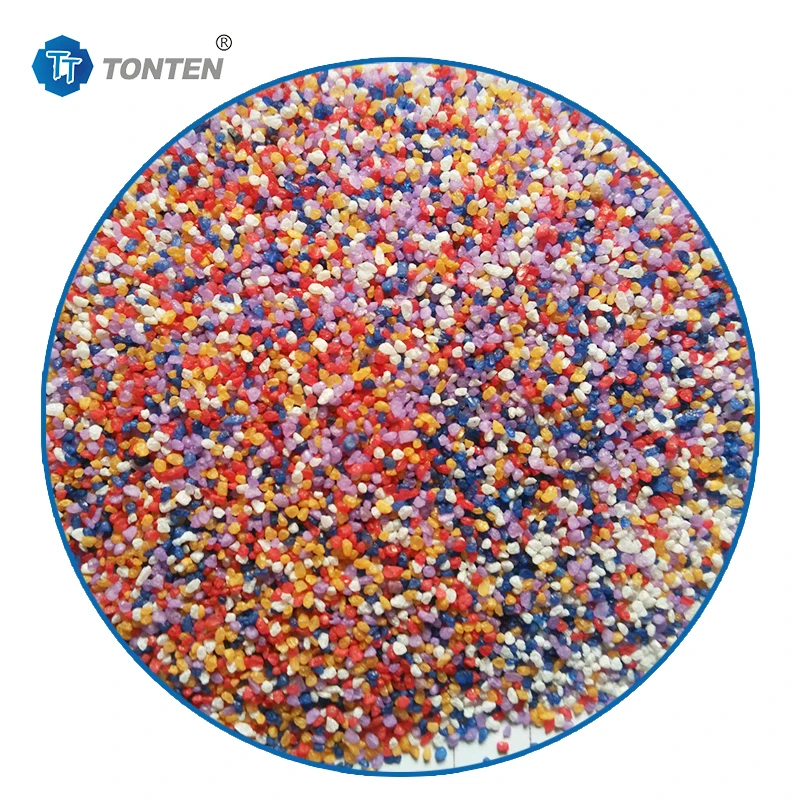

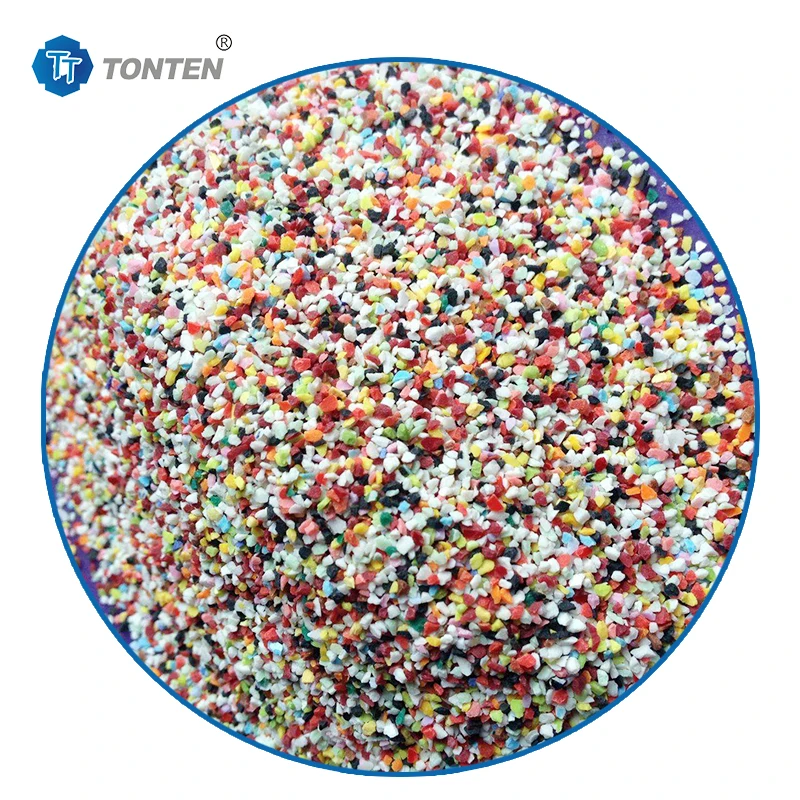

Colour | White or multi color mixed particles | White or multi color mixed particles | ||

Babbitt hardness HB a | 54-62 HB a | 64-72 HB a | ||

Infrared spectrum qualitative analysis | Urea formaldehyde resin | Melamine resin | ||

Paint removal rate (SF / min) | 0.15 SF / min | 0.15 SF / min | ||

Initiative (mg / cm2) | 0.50 mg / cm2 | 3.00 mg / cm2 | ||

Consumption rate (one cycle) | 13% | 13% | ||

Granularity selection | 12 - 16 # (1.70 - 1.20 mm),16 - 20 #( 1.20 - 0.85 mm) 20 - 30 # (0.85 - 0.60 mm),30 - 40 # ( 0.60 - 0.43 mm ) 40 - 60 # (0.43 - 0.25 mm), 60 -100 # ( 0.25 - 0.15 mm ) | |||

Application method of resin sand:

Under a certain air pressure, the granular polymer abrasive (resin sand) is sprayed onto the workpiece surface to achieve the cleaning effect quickly and without damage.

Under a certain air pressure, the granular polymer abrasive (resin sand) is sprayed onto the workpiece surface to achieve the cleaning effect quickly and without damage.

Sand Resin | ||||

Type Ⅱ | Type Ⅲ | |||

Nozzle pressure (psi)ī/ c㎡ | 45psi)ī/c㎡ | 45psiī/c㎡ | ||

Injection rate (LB / h, 0.454 kg / h) | 140~170 lb / h | 125~155 lb / h | ||

Jet grinding rate (SF / min, 929 cm2 / min) | 0.15 (140 cm2 / min) | 0.15 (140 cm2 / min) | ||

Maximum limit of corrosivity (mg / cm2) | 0.50 mg / cm2 | 3.00 mg / cm2 | ||

Average abrasive consumption (% / time) | 13% / time | 13% / time | ||

Angle | 75° | 75° | ||

Distancecm | 30-50 cm | 30-50 cm | ||

Nozzle diameter cm | 8cm | 8cm | ||

Mesh number | 16-20 mesh | 16-20 mesh | ||

Product Application

Low Viscosity Easy Flowing Resin Sand For Core Making Efficient Filling Ability

Resin sand is used for the treatment of workpiece surface, pretreatment before coating, changing the mechanical properties of workpiece and polishing of workpiece surface. Sand resin is widely used in aviation industry, shipbuilding industry, automobile, motor car, machinery manufacturing, mould, rubber, electronics and other fields.

Pretreatment (surface treatment) sand blasting before electroplating, spraying, painting, etc.

Remove oxide scale, residue and dirt from metal workpieces such as casting parts, stamping parts, welding parts and heat treatment parts; Cleaning of non-metallic surfaces, separation from hard shells containing carbon ash, etc.

For the renovation and cleaning of all moving parts such as automobiles, motorcycles and electromechanical equipment, the paint and skin can be removed.

Removal of micro burrs of machined parts and burrs on rubber surface (if applicable to the field of rubber tires).

All metal products and non-metal products (plastic, crystal, glass, etc.) have surface traces eliminated and matte fog surface treatment to improve the grade of the product surface.

Oil field tubing cleaning and valve pipeline cleaning will not produce static electricity or sparks in the cleaning process, so as to ensure the safety factor in the operation process.

Features

Low Viscosity Easy Flowing Resin Sand For Core Making Efficient Filling Ability

Quality assurance

Under a certain air pressure, the granular polymer abrasive (resin sand) is sprayed onto the workpiece surface to achieve the cleaning effect quickly and without damage.

Widely used

Resin sand is widely used in aviation industry, shipbuilding industry, automobile, motor car, machinery manufacturing, mould, rubber, electronics and other fields.

Keep a large stock of goods

Stable supply and sufficient inventory to meet customer needs

Product Photoes

Low Viscosity Easy Flowing Resin Sand For Core Making Efficient Filling Ability

Package & Shipping

The package and shipping info for resin sand:

1. The sand resin can be packed in brown paper bag or plastic woven bag.2. 25kg (55lb)/bag, 40 bags packed in a 1000kg (2200lb) bulk bag.

3. 25kg (55lb)/bag, 40 bags on a 1000kg (2200lb) pallet.

4. 1000kg (2200lb)/jumbo bag.

5. Customized packing available for resin sand iron casting.

Factory Strength

Gongyi Tonten Abrasive Co.,Ltd major in the production and processing of Abrasives, Refractory Material, Filter Material, Wear Resistance Material, Chemical Products, including Aluminium Oxide, Emery, Garnet, Copper Ore, Bauxite, Corundum, Carborundum, Fracturing Proppant, Ceramic sand, Water Clarifying Agent, and so on. We always strive for our eight core enterprise cultures, which include Study, Innovation, Humanism, Integrity, Teamwork, Efficiency, Passion, Frugality. With a complete and scientific quality control system, our credibility, strength and quality are highly recognized by the whole industry. We sincerely hope to create a brilliant future with our worldwide friends.

FAQ

1. Who are we?

We are based in Henan, China, start from 2012, sell to Eastern Europe (25.00%), North America (20.00%), Eastern Asia (20.00%), Southeast Asia (15.00%), Western Europe (10.00%), South America (10.00%). There are total about 11-50 people in our plant.

2. How can we guarantee quality?

Always a pre-production sample before mass production. Always final Inspection before shipment.

3.What can you buy from us?

Abrasives, Refractory Material, Filter Material, Wear Resistance Material, Chemical Products.

4. Why should you buy from us not from other suppliers?

We have more than 10 years experience in Abrasive industry and exported to many countries such as Korea, Japan and American markets. With a complete and scientific quality control system,we can supply customized processing according to customers requirements.

5. What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery.

Accepted Payment Currency: USD, EUR, CAD, AUD, HKD, CNY.

Accepted Payment Type: T/T, L/C, Money Gram, PayPal, Western Union, Cash.

Language Spoken: English, Chinese.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices