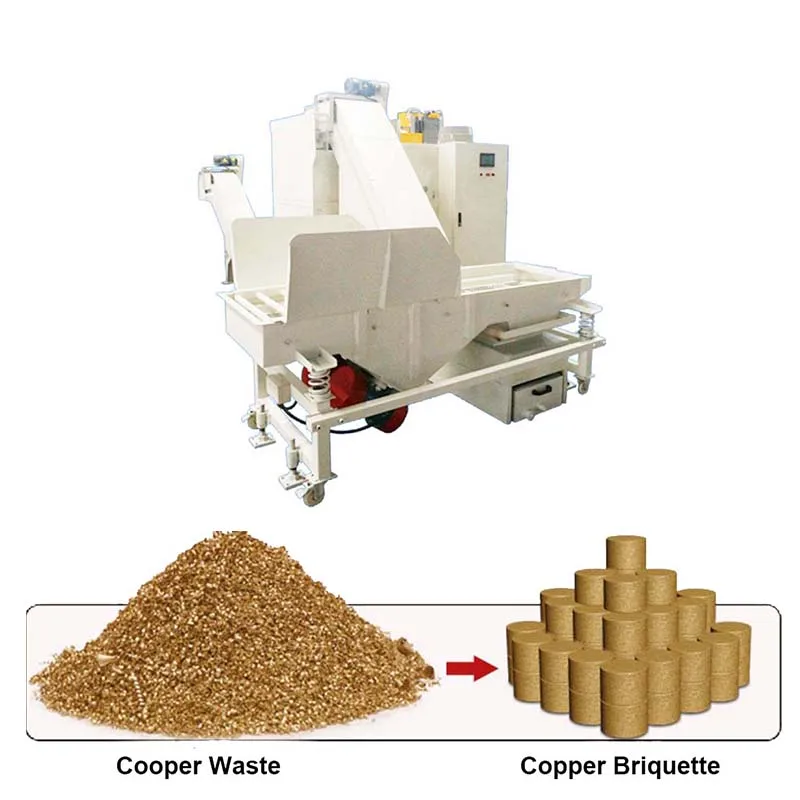

Customized briquette making machine rice husk sawdust charcoal briquette machine factory sale ball press briquette machine

- Category: >>>

- Supplier: Zhengzhou Runxiang Machinery Equipment Co. Ltd.Zhengzhou Ltd.

Share on (1601368936495):

Product Overview

Description

Product Description

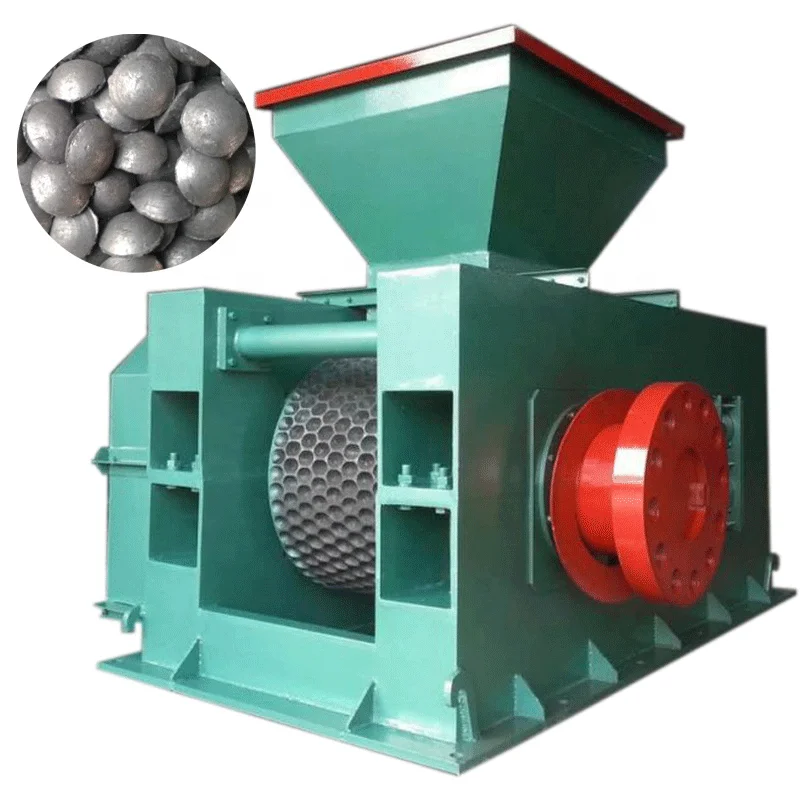

Our briquette machine are rollers pressing type. This type of briquette press can apply higher pressures and thus produce higher-density briquettes. These briquettes can be designed in oval shape, egg shape, pillow shape, square shape, etc. This machine is widely used in the coal industry and metallurgy industry.Ball press roller is cast with 65 manganese. After special heat treatment, the hardness can reach more than 58 degrees. The roller is assembled in combination and can be replaced afte wear. The ball press of mineral powder has a buffer device, which can better protect the equipment from the impact of hard objects. Mineral powder ball press is designed with ball bowl adjustable device so that the two roller ball bowl is always within the adjustable range, never dislocation.

Raw material

(1)Raw material:All kinds of coal powder,charcoal powder,biomass materials.

It can be coal powder, charcoal powder, coke powder,carbon black powder, brown coal, many mineral powder, etc. It also can be biomass materials and agricultural materials like all kinds of straw, sawdust, wood, branches, shells, husks, bio gases etc as raw materials to produce charcoal briquettes.

(2)Raw material diameter: Less than 3 mm.

(3)Raw material moisture: 8-15%.

(4)Add different binder according to your raw material and final briquettes requirements.(liquid and dry powder binder).

Specification

Model | WSCC-290 | WSCC-360 | WSCC-430 | WSCC-500 | WSCC-650 | WSC-850 |

Capacity | 1-2t/h | 3-4t/h | 6-8 t/h | 10t/h | 15t/h | 30t/h |

Roller width | 200mm | 250mm | 280mm | 300mm | 336mm | 500mm |

Diameter of roller sheer | 290mm | 360mm | 430mm | 500mm | 650mm | 850mm |

Motor power | 5.5kw | 7.5kw | 15kw | 18.5kw | 22kw | 55kw |

Size | 1.5*1.25*1.55m | 1.6*1.45*1.65m | 2.6*1.7*2.1m | 2.6*2*2.1m | 2.6*3.3*2.3m | 3.85*2.6*2.5m |

Weight | 550kg | 750kg | 880kg | 1050kg | 1600kg | 3800kg |

Details Images

This briquette machine are rollers pressing type. This type of briquette presses can apply higher pressures and thus produce higher density briquettes .These briquettes can be designed of oval shape, egg shape, pillow shape, square shape etc.This machine is widely used in coal industry and metallurgy industry.Ball press roller is cast with 65 manganese. After special heat treatment, the hardness can reach more than 58 degrees. The roller is assembled in combination and can be replaced after wear. The ball press of mineral powder has a buffer device, which can better protect the equipment from the impact of hard objects. Mineral powder ball press is designed with ball bowl adjustable device so that the two roller ball bowl is always within the adjustable range, never dislocation.

Working Principle

This briquette machine are rollers pressing type. This type of briquette presses can apply higher pressures and thus produce higher density briquettes .These briquettes can be designed of oval shape, egg shape, pillow shape, square shape etc.This machine is widely used in coal industry and metallurgy industry.Ball press roller is cast with 65 manganese. After special heat treatment, the hardness can reach more than 58 degrees. The roller is assembled in combination and can be replaced after wear. The ball press of mineral powder has a buffer device, which can better protect the equipment from the impact of hard objects. Mineral powder ball press is designed with ball bowl adjustable device so that the two roller ball bowl is always within the adjustable range, never dislocation.

Charcoal as the material

1.--Coal/charcoal powder from coal ash, coal mud, coke powder, coking coal and other kind of coal and charcoal. If the size of these materials is too big, you need to crush them into less than 3mm. If your raw materials have big size, it is difficult to press and shape in the process of making sticks.

2.The material is transferred to the conditioner by a screw feeder, then the conditioner can make different materials fully mixed.

3.The conditioner plays a key role in softening raw materials by utilizing water or steam.

4.After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning rollers in the chamber force the material through the holes of the die, thus pellets are formed.

2.The material is transferred to the conditioner by a screw feeder, then the conditioner can make different materials fully mixed.

3.The conditioner plays a key role in softening raw materials by utilizing water or steam.

4.After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning rollers in the chamber force the material through the holes of the die, thus pellets are formed.

Charcoal Powder as the material

Charcoal Powder as the material

1.The material is transferred to the conditioner by a screw feeder, then the conditioner can make different materials fully mixed.

2.The conditioner plays a key role in softening raw materials by utilizing water or steam.

3.After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning rollers in the chamber force the material through the holes of the die, thus pellets are formed.

2.The conditioner plays a key role in softening raw materials by utilizing water or steam.

3.After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning rollers in the chamber force the material through the holes of the die, thus pellets are formed.

Final production

Shapes of final briquettes: such as cylindrical,round, square, flower shapes and fan-shaped, hexagonal shape,etc. Or we can custom moulds as your requirements. Mineral Powder Briquette Machine can be used to press pulverized coal, iron powder, coke coal, aluminum powder, iron filings, iron oxide, carbon powder, charcoal powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke and other powder, powder, waste, waste slag, widely used in resistant materials, power plants, metallurgy, chemical industry, energy, transportation, heating and other industries, after the ball pressing mechanism for forming materials, energy saving and environmental protection. It is convenient for transportation, improves the utilization rate of waste materials, and has good economic and social benefits. It is also called Powder Ball Press Machine, Roller Type Briquette Machine, Fuel Making Briquette Machine, Coal Briquette Making Machine.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

FAQ

We Recommend

New Arrivals

New products from manufacturers at wholesale prices