High purity Abrasive Media Micro Glass Beads Jetting Sandblasting Glass Beads for road marking,filling

- Category: >>>

- Supplier: Zhengzhou Xinli Wear Resistant Material Co. Ltd.Zhengzhou Ltd.

Share on (1601370396723):

Product Overview

Description

Product Description

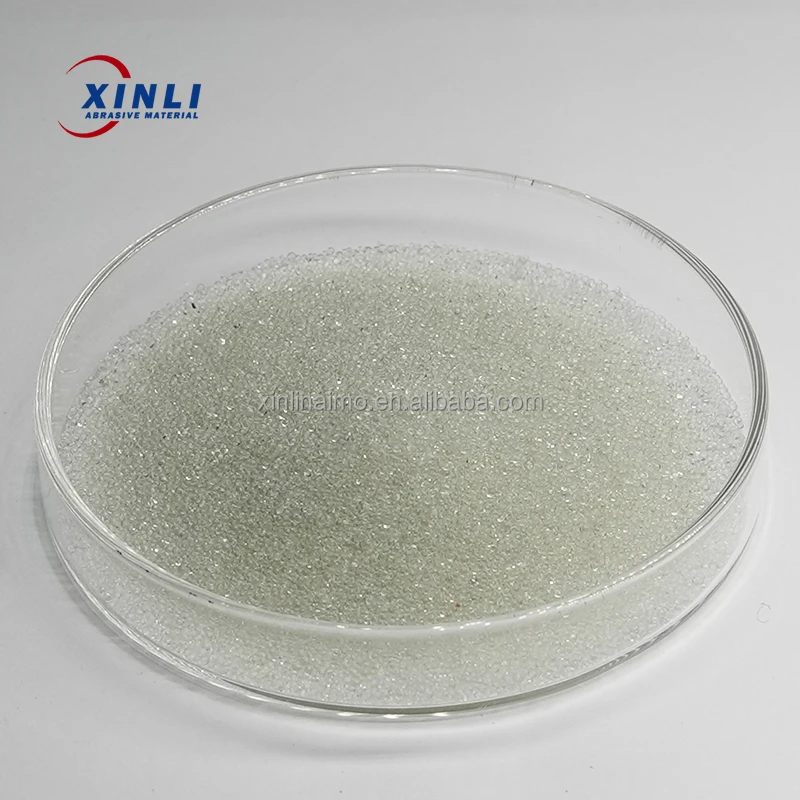

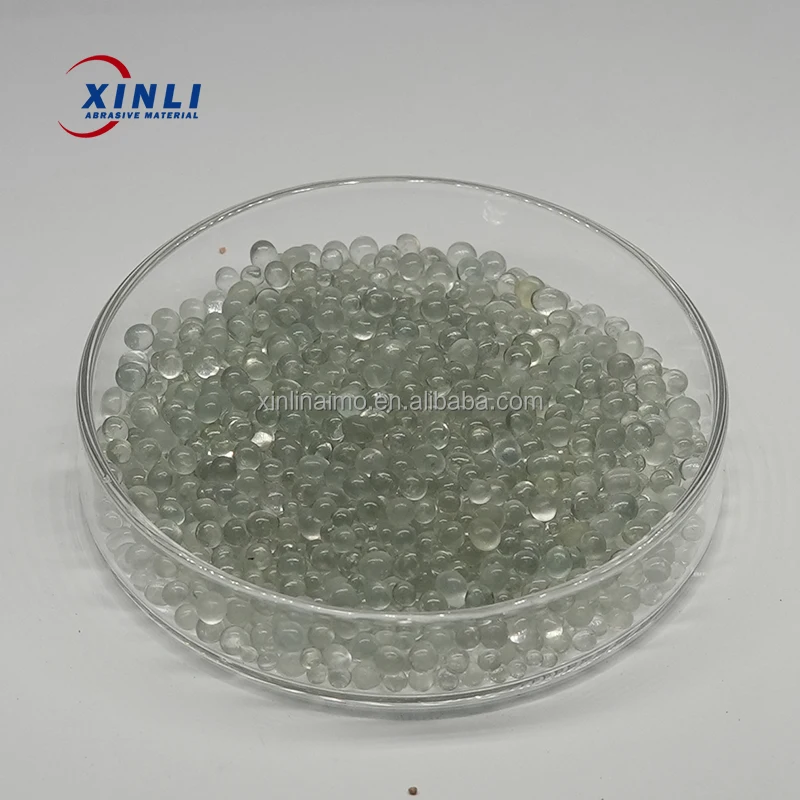

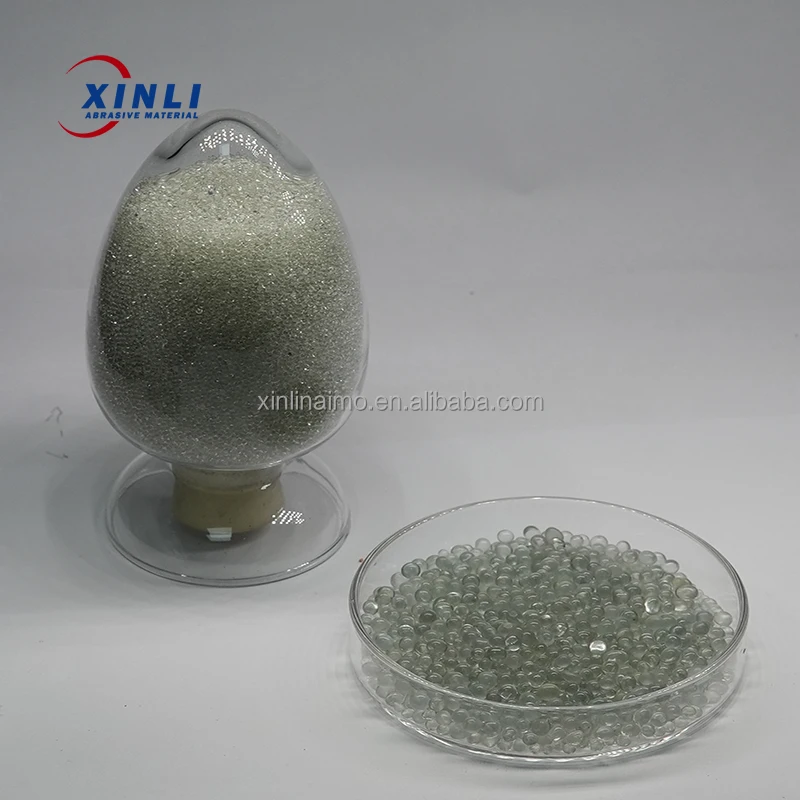

Glass Beads

Glass beads are a spherical, iron-free blasting medium. Taking hardened spherical soda lime glass as raw materials, glass beads are a multi-faceted and commonly used media. Micro glass beads are one of the most common reusable blasting media, which is ideal for non-aggressive cleaning and for producing visually attractive surfaces.

Specifications

Application | Available Sizes | ||||||

Sandblasting | 20# 30# 40# 40# 60# 70# 80# 90# 120# 140# 150# 170# 180# 200# 220# 240# 325# | ||||||

Grinding | 0.8-1mm 1-1.5mm 1.5-2mm 2-2.5mm 2.5-3mm 3.5-4mm 4-4.5mm 4-5mm 5-6mm 6-7mm | ||||||

Road marking | 30-80 mesh 20-40 mesh BS6088A BS6088B | ||||||

Chemical Composition

SiO2 | ≥65.0% |

Na2O | ≤14.0% |

CaO | ≤8.0% |

MgO | ≤2.5% |

Al2O3 | 0.5-2.0% |

K2O | ≤1.50% |

Fe2O3 | ≥0.15% |

Advantages:

Does not cause dimensional change to the base material

Environmentally friendlier than chemical treatments

Leave even, spherical impressions on blasted part surface

Low breakdown rate

Lower disposal & maintenance costs

Soda Lime glass does not release toxins (no free silica)

Suitable for pressure, suction, wet and dry blasting equipment

Will not contaminate or leave residue on work pieces

Environmentally friendlier than chemical treatments

Leave even, spherical impressions on blasted part surface

Low breakdown rate

Lower disposal & maintenance costs

Soda Lime glass does not release toxins (no free silica)

Suitable for pressure, suction, wet and dry blasting equipment

Will not contaminate or leave residue on work pieces

Applications

1. Blast-cleaning--removing rust and scale from metallic surfaces, removing mould residues from casting and removing tempering

colour

2. Surface finishing--finishing surfaces to achieve specific visual effects

3. Used as disperser, grinding media and filter material in day, paint, ink and chemical industry

4. Road marking

colour

2. Surface finishing--finishing surfaces to achieve specific visual effects

3. Used as disperser, grinding media and filter material in day, paint, ink and chemical industry

4. Road marking

Company Profile

Founded in 1996, Zhengzhou Xinli Wear-resistant Materials Co., Ltd. Is a professional integrative enterprise specializing in R&D, producing, and selling various wear-resistant materials. Such as white fused alumina, white corundum powder, alumina powder, green silicon carbide powder, brown fused alumina, brown corundum powder and other wear-resistant materials. With about 25 years experiences, Zhengzhou Xinli has become the first enterprise that achieves the original crystal granularity to standard 0.3μm, which can help to gain the effect of metal mirror polishing.

The company has passed iso9001:2015 quality management system certification. It has 2 dumping furnaces and 3 fixed furnaces, 12000V magnetic separator, ball mill, Bamako, OMAX resistance and laser particle size detector and other advanced production equipment and testing instruments. Adhere to innovation, standardized, refined production, so that every customer can use stable quality, price concessions products is our consistent goal!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices