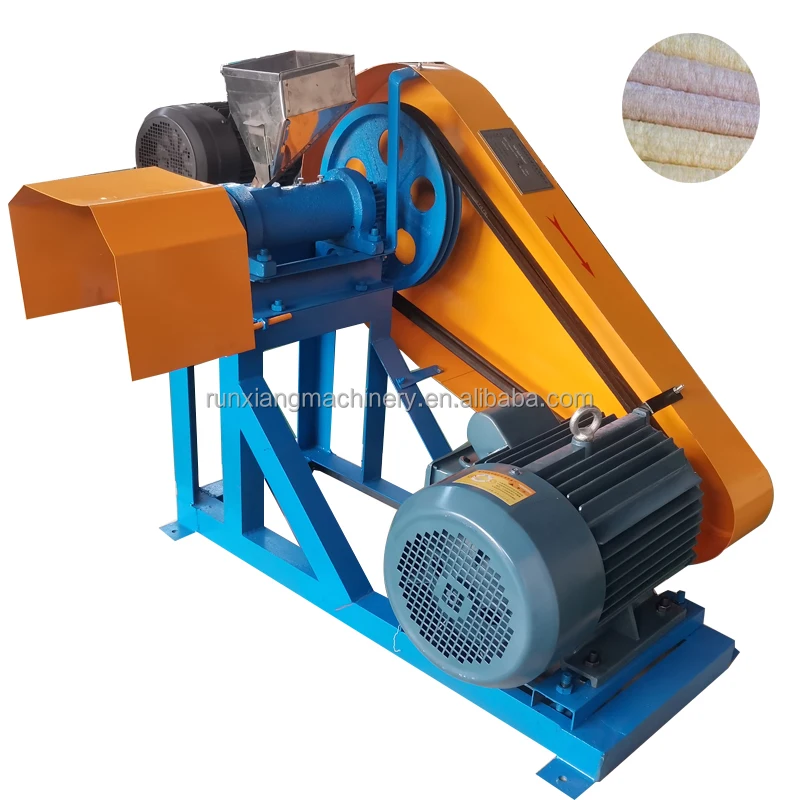

New Single Screw Electric Mini Extruder Machine Snack for Corn/Rice/Beans

- Category: >>>

- Supplier: Lerford Machine LLCLerford LLC

Share on (1601375287329):

Product Overview

Description

Product Description

The utility model relates to equipment for processing puffed food, such as rice, corn, soybean, wheat, etc.The main principle of its operation is that mechanical energy is converted into heat energy. The heat generated when the machine is turned squeezes the food until it is cooked. The most obvious characteristic of the expanded food is its larger size. A machine that combines mixing, shearing, heating, rolling, cooling and forming

The Low-configuration snack food puff machine is a specialized type of extruder machine that is primarily used in the food industry for the production of snack foods. It works by extruding and puffing various ingredients such as cornmeal, rice, wheat, and potato starch to create a crispy, crunchy texture.

The snack food puff machine consists of several important parts, including the feeding system, extruder, and cutting system.

The feeding system is responsible for feeding the raw materials into the extruder, while the extruder is responsible for mixing and shaping the ingredients. The cutting system then cuts the extruded product into the desired size and shape.

The snack food puff machine consists of several important parts, including the feeding system, extruder, and cutting system.

The feeding system is responsible for feeding the raw materials into the extruder, while the extruder is responsible for mixing and shaping the ingredients. The cutting system then cuts the extruded product into the desired size and shape.

Application

The raw materials used in the snack food puffing machine vary depending on the type of snack being produced. Generally, grains like corn, rice, wheat, barley, and oats are used as the main ingredients. Other ingredients like sugar, salt, seasonings, and flavorings can also be added to enhance taste and texture.

The low-configuration snack food puff machine is used in a variety of applications, including the production of snack foods such as corn puffs, potato chips, and rice cakes. It is an ideal option for small to medium-sized businesses that want to produce high-quality snack foods at a low cost.

1. This food inflating machine can be used for different areas such as people food industry, fish food industry etc.

2. The main material can be wheat, rice, corn, broomcorn, maize, beans grits and powder etc. The size of the finished products can be adjusted according to customers’ different requirements.

1. This food inflating machine can be used for different areas such as people food industry, fish food industry etc.

2. The main material can be wheat, rice, corn, broomcorn, maize, beans grits and powder etc. The size of the finished products can be adjusted according to customers’ different requirements.

Feature:

The key advantages of the snack food extruder machine include its low cost, ease of use, and versatility. It is capable of producing a wide range of snack foods with different flavors, shapes, and sizes. The machine is also easy to operate, clean, and maintain, making it a popular choice among food manufacturers of all sizes.

1. Small volume, it easy operation and high economic2. Can change the shapes of moulds3. Make corn and rice into various shapes

4.Using corn, millet, broomcorn as raw material, and changing the shapes of moulds, this series of bulking machine can make grain into various shapes of leisure puffing food, such as hollow, clavate, round, spherical, spring type and etc.

1. Small volume, it easy operation and high economic2. Can change the shapes of moulds3. Make corn and rice into various shapes

4.Using corn, millet, broomcorn as raw material, and changing the shapes of moulds, this series of bulking machine can make grain into various shapes of leisure puffing food, such as hollow, clavate, round, spherical, spring type and etc.

Size Information

Model | WSPH-40 | WSP-50 | WSPH-80 | WSPH-190 | ||||

Main material | rice, corn, broomcorn, maize, beans etc | |||||||

Motor power | 4.5-5.5kw, 380&220V or 6-8HP | 4-5.5kw, 380&220V, or 6-8HP (with 2pcs of V belts) | 5.5-11kw, 380v, or 6-8HP (dia 90-100mm) | 15kw, 380v, or F175 6-8HP (with 2pcs of V belts, dia 90-100mm) | ||||

Output | 30-40kg/hour | 40-50kg/h | 60-80kg/h | 100-120kg/h | ||||

Rotated speed | 500-600rp/min | 500-600rp/min | 440-550r/min | 440-550rp/min | ||||

Weight | 150kg | 180kg | 200kg | 220kg | ||||

Packing size | 1080*670*920mm | 1180*770*920mm | 1280*770*1020mm | 1380*870*1120mm | ||||

The Details of Product

Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Packaging

All our exported products are packed in fumigation-free wooden boxes to ensure the safety of product transportation, please rest assured

Related machinery

Company Introduction

We Recommend

New Arrivals

New products from manufacturers at wholesale prices