Skywin Automatic Small Scale Potato Chips Production Line/Potato Chip Making Machine

- Category: >>>

- Supplier: Skywin Foodstuff Machinery Co. Ltd.Skywin Ltd.

Share on (1700005636706):

Product Overview

Description

Skywin Automatic Small Scale Potato Chips Production Line/Potato Chip Making Machine

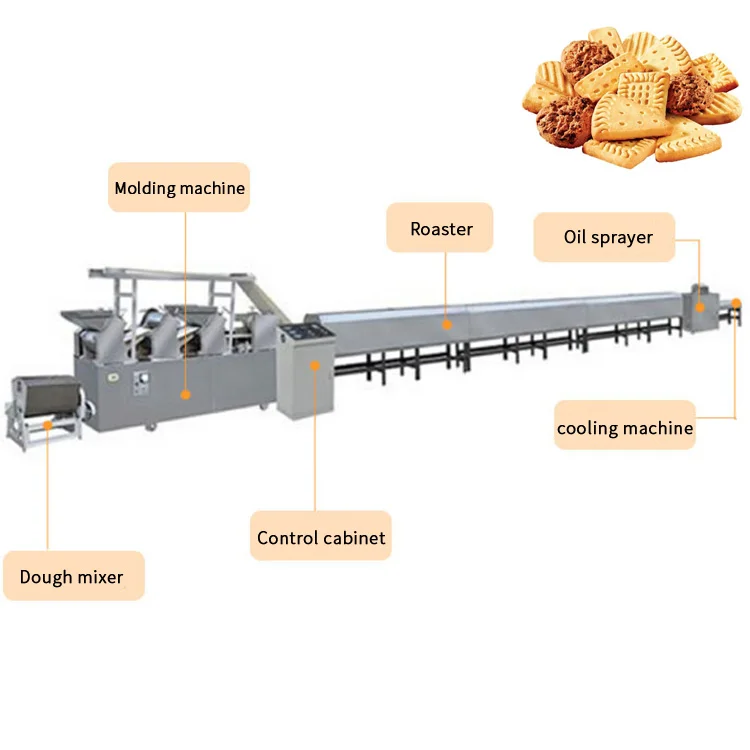

A whole line consist of:

· 1.Horizontal dough mixer, 250kg/batch, vertical dough mixer 500kg/batch

· 2.Automatic dough tipper and feeding system

· 3.Three-roll combination sheeter for feeding and sheeting dough

· 4.Laminator for overlapping dough to sheeting on gauge rolls, included cream spreading machine.

· 5.Gauge rolls

· 6.Rotary cutting machine for hard biscuit forming

· 7.Scrap collection and return system

· 8.Rotary moulder for soft biscuit forming

· 9.Salt/sugar spreading machine

· 10.Tunnel oven, electric, indirect gas fried or hybrid gas oven for option, length cis depend on capacity.

· 11.Oil spraying machine

· 12.Turning machine 180degree or 90degree design as per the plant length

· 14.Cooling conveyor

· 14.Biscuit stacking machine (start wheel stacker or penny stacker)

2019 Skywin Exhibition

Warm welcome to visit our booth

Please contact Kaylee

Whatsapp/Wechat/Telegram:+86 136 9045 4618

Dough mixer(horizontal & verticle)

This machine is used in dough mixing, it is suitable for hard biscuit and soft biscuit.The dough through mixing, dough surface will be good elasticity and smoothness.Its capacity including: 50kg,150kg,250kg,400kg,700kg. The mixing blade and bucket are made of 304SS,U-form bucket has temperature insulation function,simple operation and safety.

Three-roll sheeter

3pc Roller as T from, it can press the dough twice through one roller.

And it is convenience for the dough go inside the Roller for pressing.

model | Three-roll sheeter | Thickness of dough sheet | Dimension |

| 600 | 1 | 5-20mm | L950xW1240xH1650mm |

| 800 | 1 | 5-20mm | L950xW1240xH1650mm |

| 1000 | 1 | 5-20mm | L950xW1240xH1650mm |

Rotary cutter

When dough sheet go through rotary cutter machine,it will be cut and shaped by moulds.And the scrap will be conveyed to the hopper by recycle device after Separating.

Rotary mould

Rotary moulder is used in making soft biscuit.

After dough crushed by roller then go through moulder to forming.

Tunnel oven (electric,indirect gas, direct gas, hybirdgas)

Electric baking oven is used electricity as energy. It’s high efficiency, long usage, easy maintenance.

Gas baking oven is used natural gas as energy. It’s more scientific and safe, high efficiency rapid heating, save enerdy, clean and simple operation.

Stacker(star wheel &penny stacker)

One is Star wheel structure, it is composed by transition conveyor, divided biscuits in order rows and stacking, total two conveyor belts.

The other is Panny Biscuit stacker, usually it combined by 3 units of different speed conveyors, the speed from fast to slow,through discrepancy speed to make the biscuits lay down as lines, to easy transport to packaging machine

Skywin Machinery (Group) Co.,Ltd

Contact: Kaylee Cao (Ms.)

Mobile/Wechat/Whatsapp: 008613690454618

Welcome to visit our factory! please contact us at anytime!!!

Warmly welcome you to visit our factory.

From Guangzhou Baiyun Airport 45 minutes trip (by car)

From Guangzhou Nan Railway Station, 20 minutes trip (by car)

Step 1: Mechanical surface coated with preservative solution (to protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

We Recommend

New Arrivals

New products from manufacturers at wholesale prices