plastic tool parts 3d printer OEM injection assembly molding services

- Category: >>>

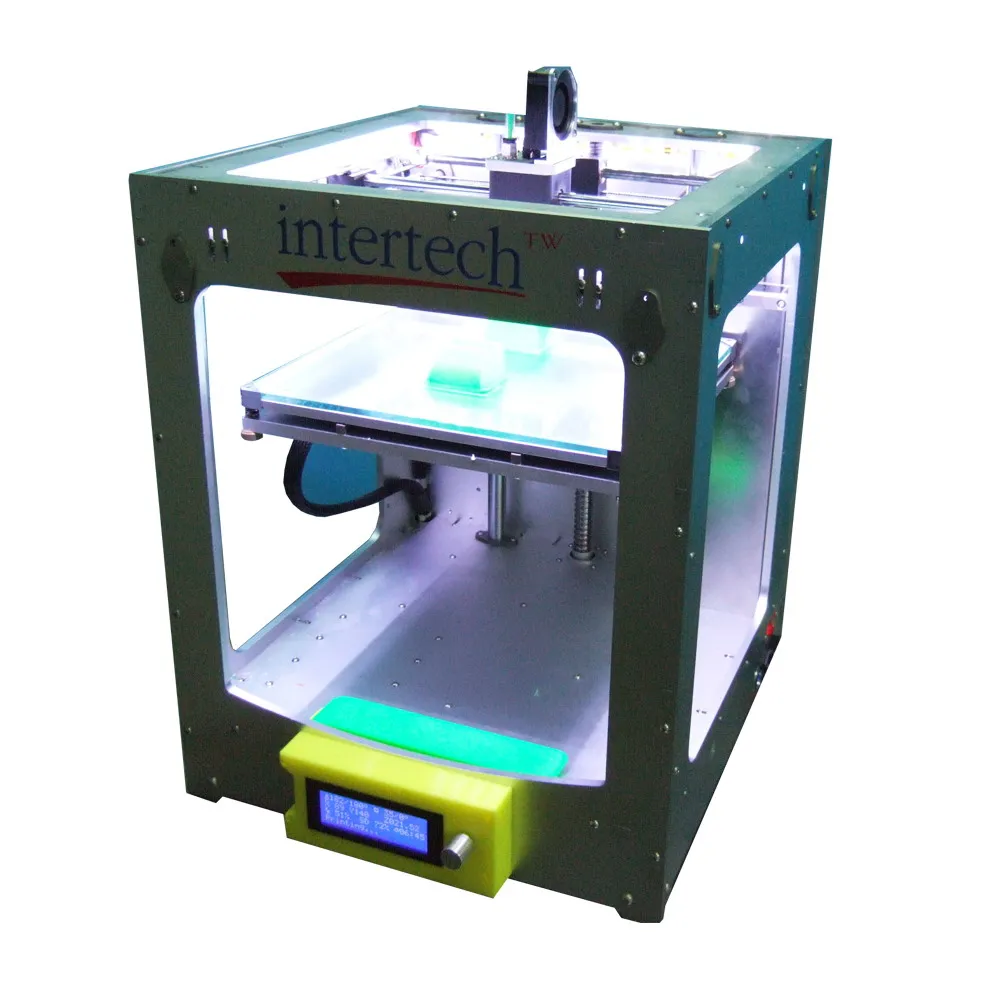

- Supplier: INTERTECH MACHINERY INCORPORATIONINTERTECH INCORPORATION

Share on (1877556149):

Product Overview

Description

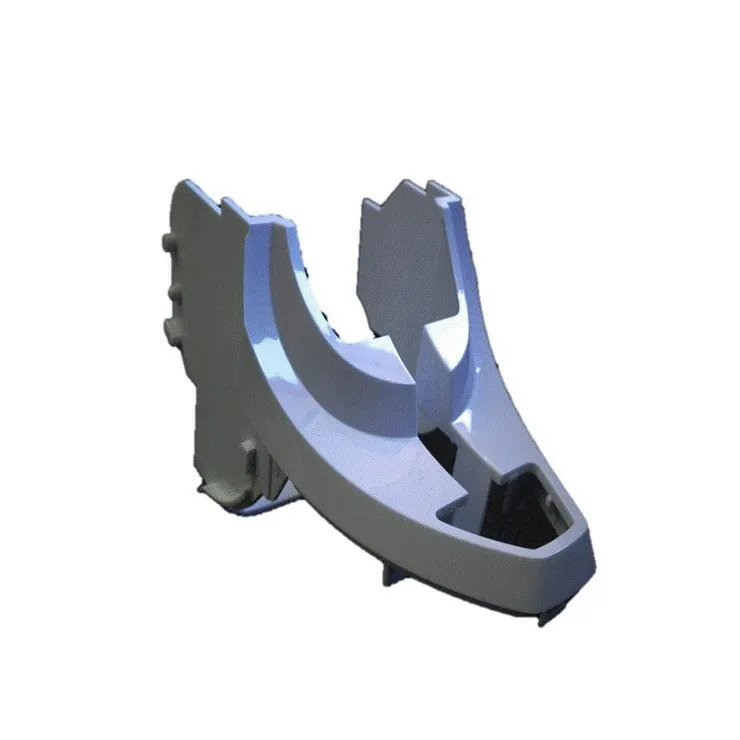

Plastic tool parts 3d printer OEM injection assembly molding services

For related product information, please kindly refer to the following table:

Medical |

|

|

|

|

Car |

|

|

|

|

Fittings |

|

|

|

|

Led |

|

|

|

The most important service is we accept custom designed orders. As long as you offer the …Parts 2D, 3D, SAMPLE, PHOTO OF YOUR DESIGN and state clearly the mold cavity number,mold steel grade and required product quantity and material, then, we can quote our best price to you. Sample order is available after our discussion!

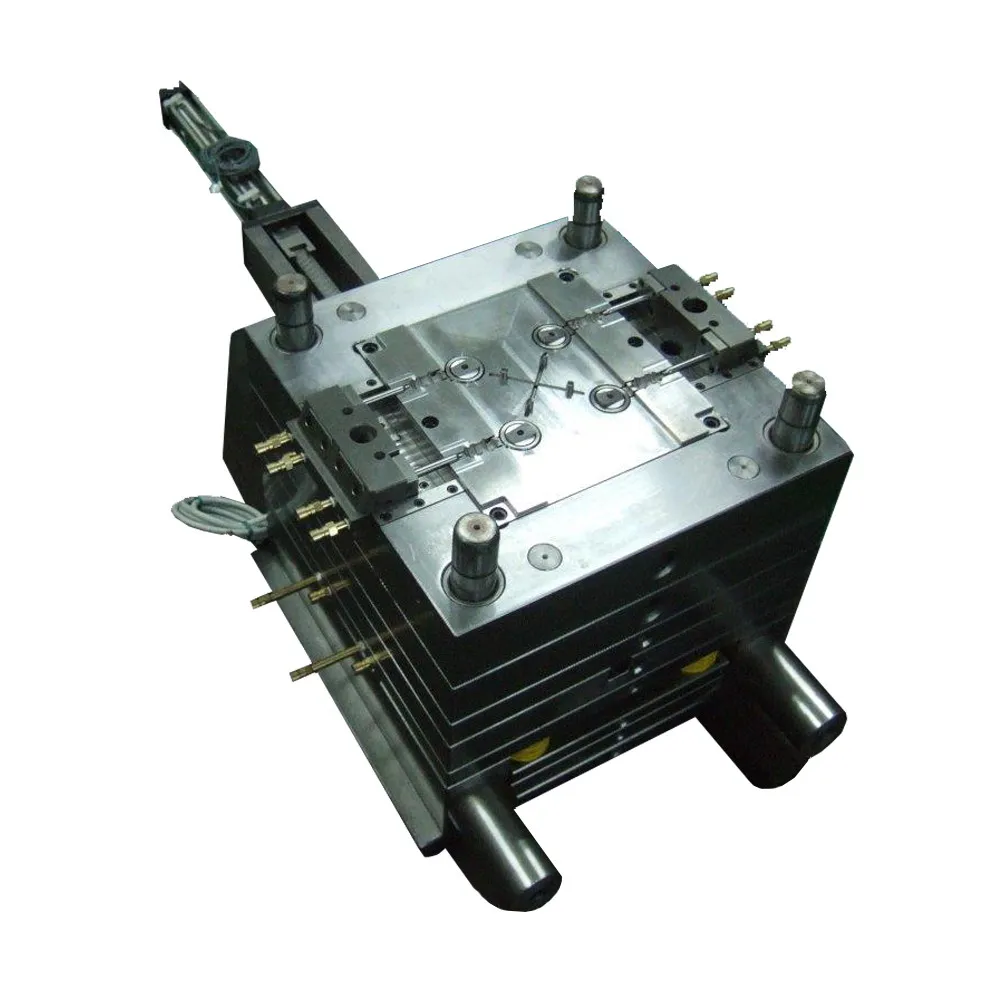

1. Customized Making:

- Per your drawings or samples, we can customize your mold.

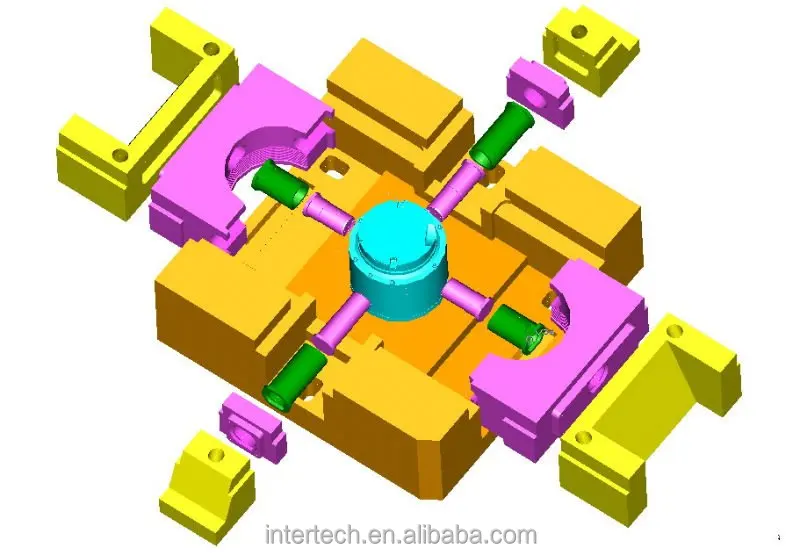

- Per your requirement, we can modify and design your parts structure to establish the overall 3D effect drawing. And per above 3D drawing, we can provide mold making quotation and product molding quotation to you to help you to do the entire costing analysis.

2. Prototype Making:

- in initial stage, after confirming the product design, size, material, and price…etc, if you need, before starting to make the real mold, we can make the prototype for you to help you understanding the product detail and its outlooking (Ps. we will estimate the prototype cost report to you from 3D printing or from NC milling way).

3. Purchase Contract Making:

If both of us agree to sign the contract, we will mention the working detail, lead time, inspection standard, payment term information…etc on the contract.

4. During the mold manufacturing period:

- We will send the update working progress report in every 1-2 week with photos.

- Before commencing making the mold and the machining process, if customer needs to adjust the product’s shape slightly, we will not charge the extra cost.

-If the machining process is on-going, and customer needs to adjust the product design, we will study and give our report to see whether we should charge extra cost or not.

-We will send T1, T2 or T3 samples till meeting customer’s satisfaction.

5. If customer places the product production orders to us:

- After the final trial samples is approval by customer, if customer places the product production to us, we will be responsible for the mold maintenance and performance for all.

6. Packing information:

- For mold, we pack with standard exported wooden box with fumigation process.

- For product, if there is no specific packing requirement, we will use regular carton box and bag (free of charge). If customer requires specific packing way,

We can help customer to do the assembly, packing and the printing from case to case.

7. Transportation:

- Customers can use their own forwarder or we can help customer to arrange any sea or air transportation forwarder to deliver the goods to customer’s address.

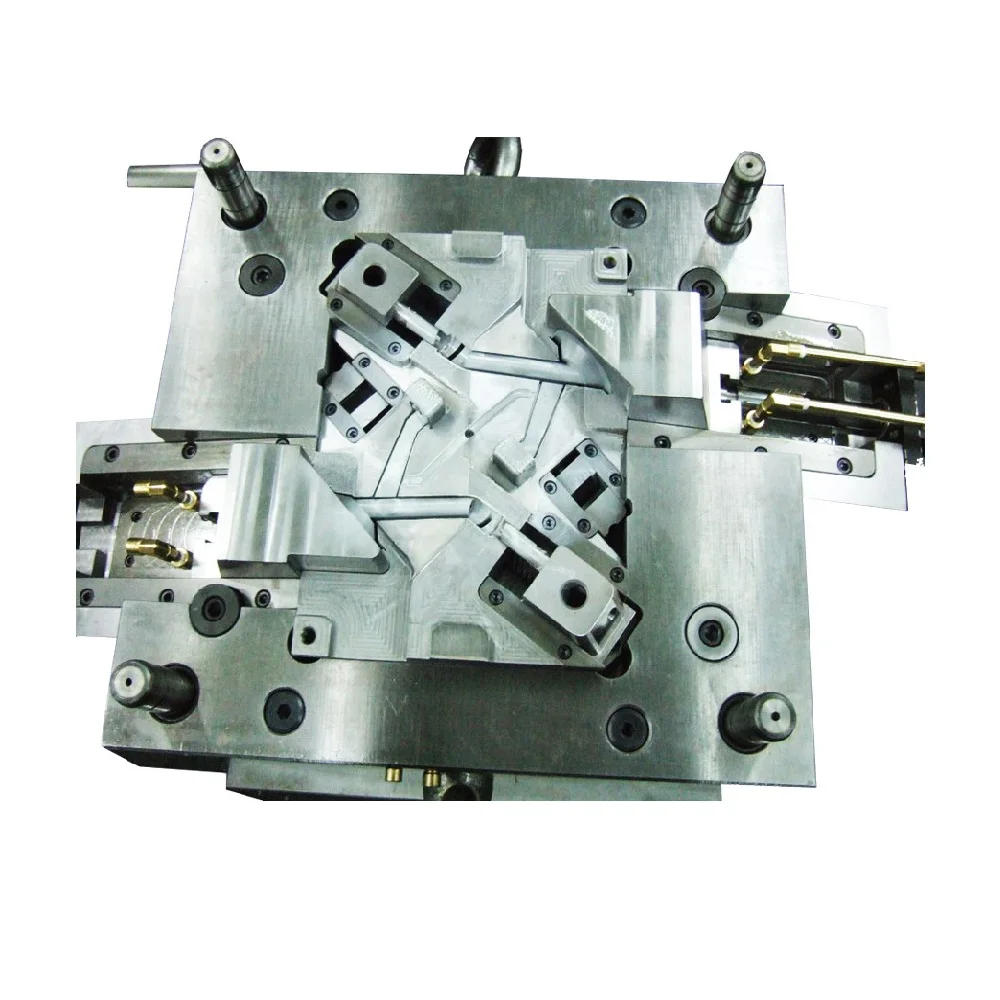

Quality Management Process

we check mold steel hardness and size precision. We test the mold and measure the parts and discuss all the time with customer with good report.

Dimension checking report

All sizes of mold and products are strict checked by our professional engineers in shop

Precision checking

For each time of mold testing, we do key dimensional check as per customer's request.

For each time of mold testing, we do key dimensional check as per customer's request.

Testing Machinery

1. Push-Pull Gage

2. STEREO MICROSCOPES

3. Optical Micro image Measurers

4. Profile Projectors

Mold Making Machine Equipment

1. EDM 2. Lathing machine

3. Milling Machine 4. Grinding machine

5. Drilling Machine 6. Band saw

7. 3D Printer 8. CNC Lathing

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

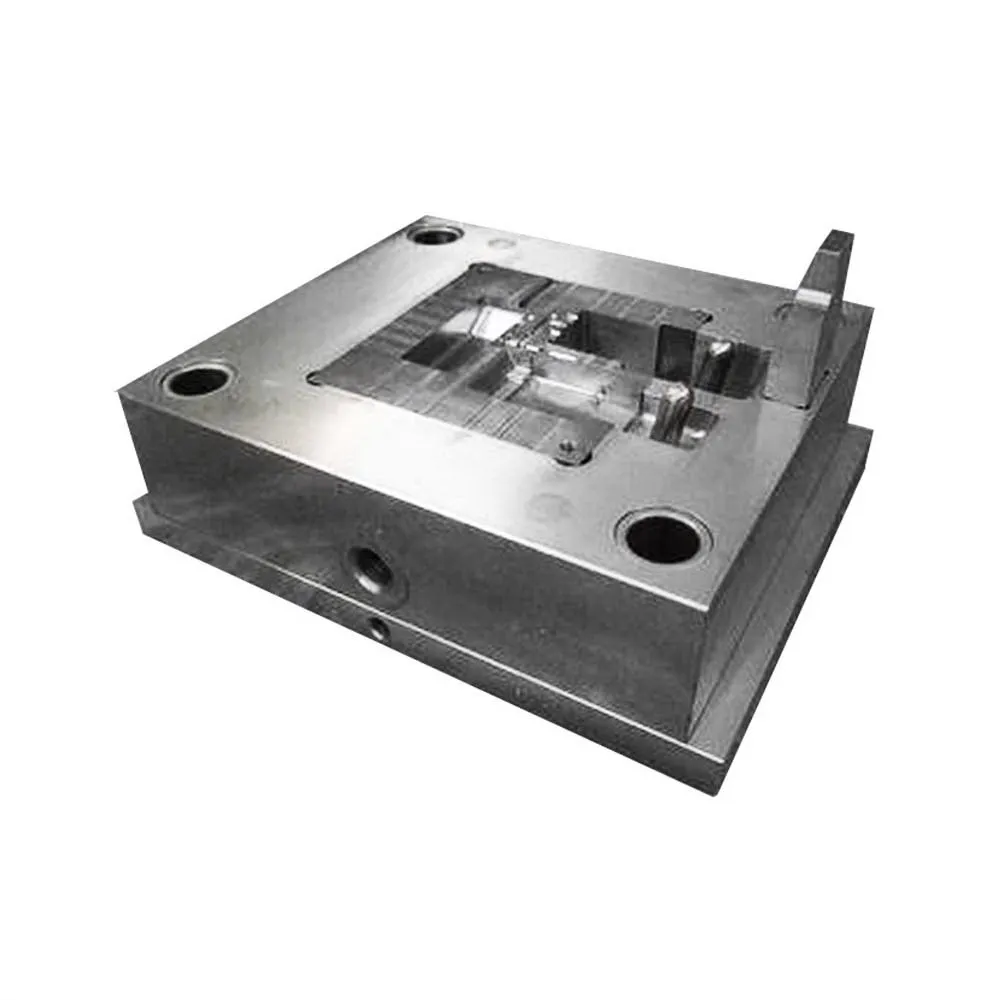

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices