Industrial chemical mineral inorganic fertilizer powder auger precompression double roller compact briquetting production line

- Category: >>>

- Supplier: Changzhou Shengong Granulation Equipment Co. Ltd.

Share on (490109053):

Product Overview

Description

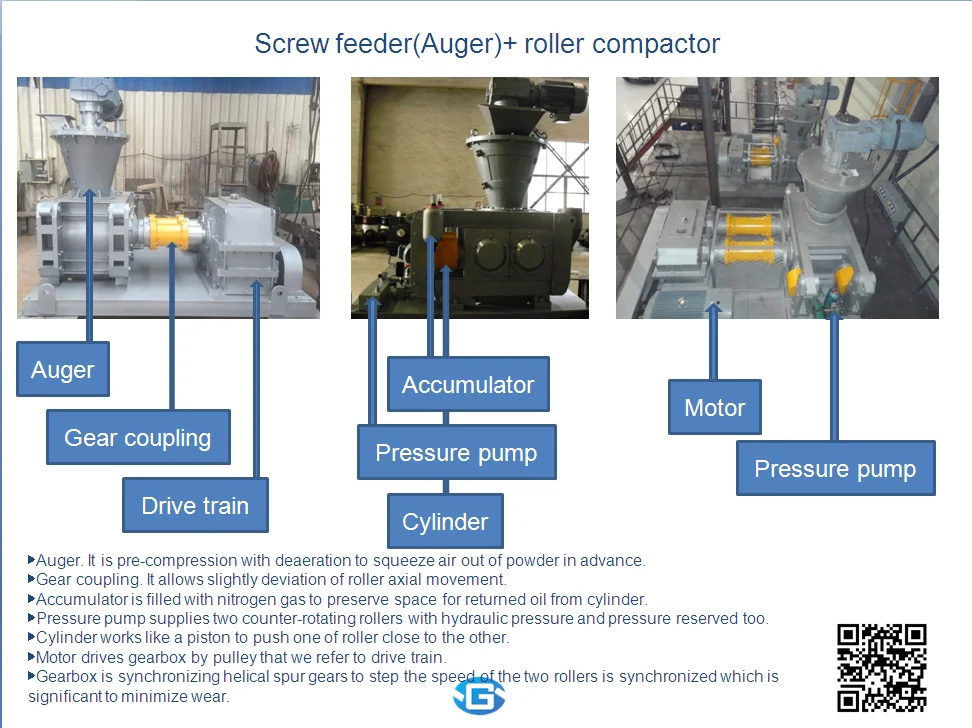

Roller type briquetting machine operating principle:

The briquetting machine adopts two rollers compaction. Between 2 rollers, there is a gap. One roller is fixed and the other is floating. With the support of hydraulic pistons, the floating roller is pushed close to the other and the hydraulic system can has the action of compensation and protection. In the surface of the roller, it is profiled with plenty of die holes of "Eggs" shape. Feedstock (powders) is fed into the gap between two rollers by screw. With rotating in reverse of two rollers, powder are compacted into Final product directly.

Roller type briquetting machine parameter:

a).roller diameter: 600mm width: 310mm

b).roller turning speed:12-18rpm.

c).screw feeder: 11kw motor with VFD

d).accumulator pre-pressurization: 8 - 10Mpa

e).linear pressure: 55kN/cm

f). briquette size: 41*28*22mm

g).power of compactor: 90kw

h).installed capacity: about 104kw

i).dimension (L×W×H) : 3660×2450×2700mm

j).weight: about 22t

k).briquette output:8-10t/h

l). briquette shape: oval/oblate/almond

Roller type briquetting production line components:

Roller type briquetting machine applications:

1.fertilizer:

Potassium Sulfate(SOP), potassium chloride, Russia red potassium, potassium nitrate, ammonium chloride, Ammonium Phosphate Monobasic, Diammonium phosphate(DAP), NPK compound fertilizer, import Russia Potassium Sulfate(SOP), ground phosphorite, NH4SO4, concentrated superphosphate, humic acid etc.

2.powder material

zinc oxide, lead oxide, calcium chloride, calcium phosphate, High test bleaching powder, cryolite, chemical inhibitor, silica, Isophthalodinitrile etc.

3.chemical raw material, fine chemical material

4.FGD gypsum

5.coal powder

Note: It takes FGD gypsum for example, varies in accordance with the material to be briquetted.

Our factory is small but dedicated in only roller compactor for granulating and briquetting.

Roller type briquetting production line (A type produces small angular (irregular) granules)

Difference of Roller type briquetting production line type A and type B.

Roller type briquetting machine consists of screw feeder (upper taper) and double roller compactor

Roller type briquetting machine peripheral equipments

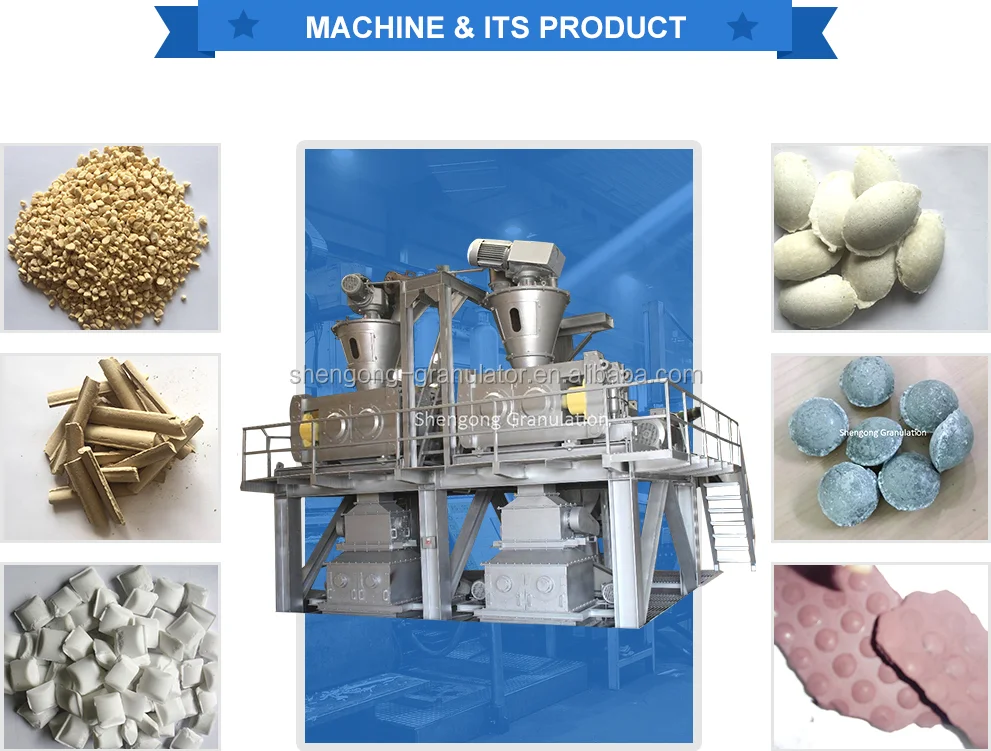

Briquettes vairable shape

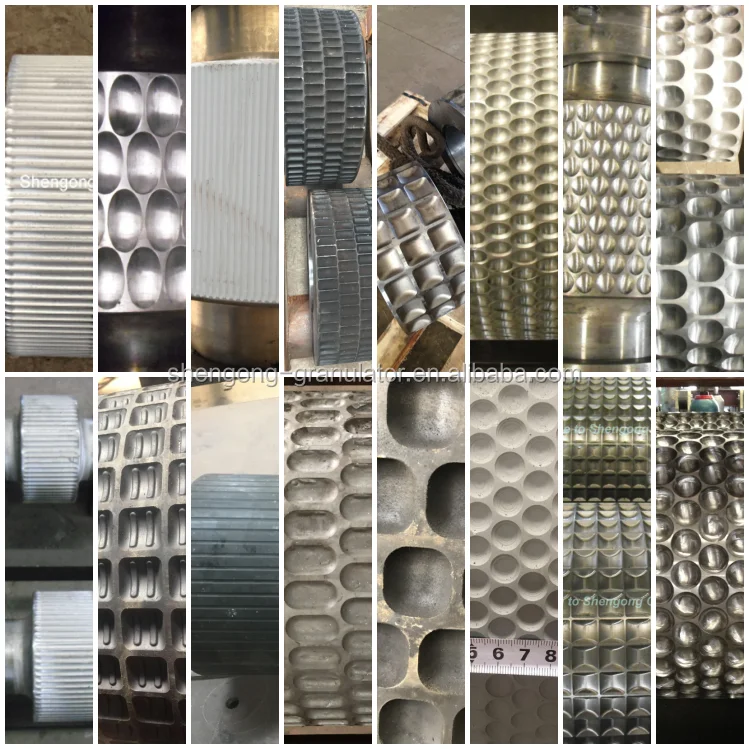

Briquettes and its rollers

Roller type briquetting production line and its peripheral equipments are being loaded.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices