Multimedia sand filter , automatic sand filter,actived carbon filter for Water treatment plant

- Category: >>>

- Supplier: Jiangsu YLD Water Processing Equipment Co. Ltd.Jiangsu Ltd.

Share on (60071629748):

Product Overview

Description

Multimedia sand filter/carbon filter for water treatment plant

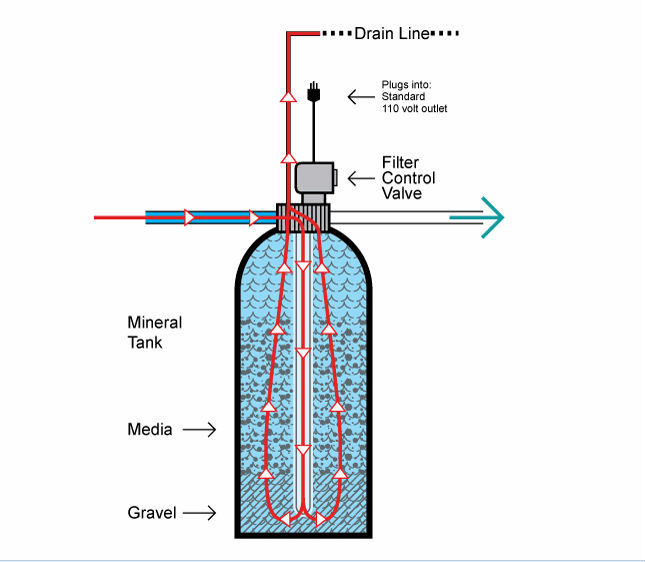

Sand filters are the oldest and most basic form of water filtration and originally consisted of large volumes of sand through which water simply percolated. Modern systems however now include various media layers which allows much more efficient filtration in smaller vessels.

Multi-media sand filters normally consist of three media layers (ie. support base gravel, micro screened sand and anthracite) and are a very economical means of primary filtration to remove the bulk of suspended solids. They are particularly efficient on surface waters for the removal of grit, sediment, turbidity and organic matter but also widely used on oxidised iron ('rust') and other precipitated contaminants such as manganese or scale particles.

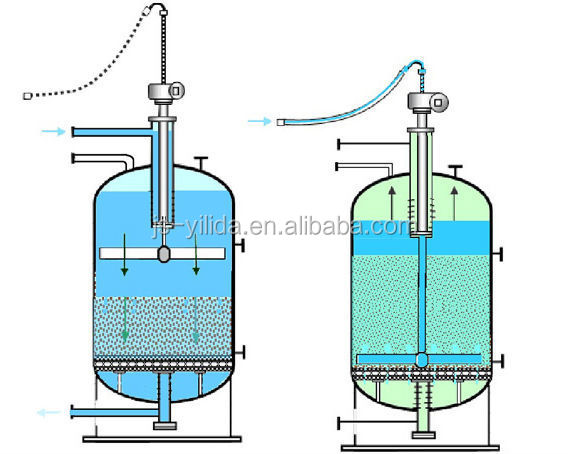

Multi-media filters are periodically backwashed (either automatically or manually) by simply reversing the flow and this flushes to waste the accumulated sediment and also regrades the filter media layers.

Operation and maintenance is extremely simple. After initial set-up, the system is virtually self sustaining. With the Performa Head, back-flushing and clearing of trapped contaminates occurs automatically.

Quartz sand filter

Quartz sand filter can effectively remove suspended solids in the water and has significant effects on the removal of colloids, iron, organics, pesticides, manganese, bacteria, viruses and other pollutants in the water. besides advantages of small filtration resistance. large specific surface area, strong acid and alkali resistance, resistance to oxidation, PH scope of 2-13 and anti-pollution. As a unique advantages of the quartz sand filter, the filter is able to run self-adaptively through the optimization of the filter media and filter design, so that the filter material has a strong adaptivity to raw water concentration, operating conditions, pre-disposal process. i.e. the filter bed automatically forms a non-uniform state during filtration, which helps to guarantee the water quality under a variety of operating conditions and spread the filter material when backwashing, achieving good cleaning effect. The sand filter has advantages including fast filtering speed, high filtration precision and large interception capacity, etc. The filter is used in the industrial water, domestic water and municipal water systems requiring outflow turbidity of not greater than 5mg/I and complying with drinking water quality standards and for the removal of suspended solid sand solids in industrial wastewater: it can be used as ion exchange and pretreatment for softening desalination system and can also be used in the coarse filtration of water with undemanding industrial water quality, swimming pool circular processing system and cooling circulating water purification system.

Activated carbon filter

Activated carbon filter is used for the removal of color, taste, residual chlorine and organics its main mode of action is adsorption. Activated carbon is an artificial sorbent. Activated carbon has developed pore structure and huge specific surface area, so it has a strong adsorption capacity for the dissolved organics in the water, such as benzene and phenolic compounds, and has better removal efficiency for organic pollutants which are hard to be removed by biological and chemical methods, such as chroma, stench, surfactants, synthetic detergents and dyes, etc. Granular activated carbon is able to remove 85% of Ag A , Cr2 + and Cr04 A 2 in the water Through the activated carbon filter bed, the suspended solid in the water is less than 0.1 mg/L, COD removal rate is generally 40% to 50% and free chlorine is less than 0.1mg/I. It can be used as pretreatment of ion exchange, electrodialysis and reverse osmosis in pure water technology so as to remove organics, colloids and residual chlorine; it can be also used as an advanced treatment mean after the secondary treatment to ensure the quality of reusewater.

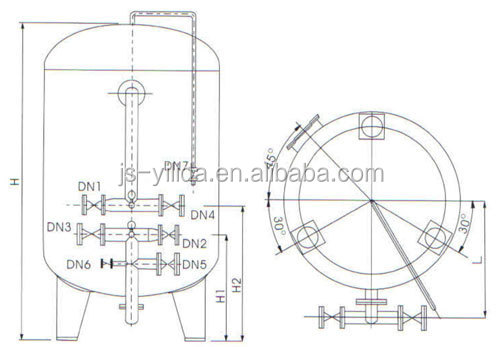

Five(5) valves on filter tank:

DN1-water-inlet valve

DN2-wash valve

DN3-backwash valve

DN4-drain valve

DN5-water-outlet valve

DN6- drain outlet

When the system is in a filtered State, the water flow through the water distributor which was unallowed,comply with shell,the water flow through the filter layer at the horizontal - flow state,as the water flowthe filter material layer, impurities are trapped within the filter layer,The filtered water is collected and evenly through water outflow,flowing parallel,at the high speed ,the filter could work well,and it can reach better effect too.

Backwash

With the continued accumulation of impurities in filter material layers, increasing loss of head,as the loss of head reaches a certain set limit, system will automatically be converted to the anti - washing, cleaning accumulation of impurities,

Backwashing happens at the differential pressure reaches 0. 05-0. 07Mpa,each time.and while the backwashing is over the differential pressure will back to 0.02-0.03Mpa.

Application:

(1) Pre-treatment for RO system, electrodialysis, ion exchange device, UF etc .

(2) Filtering treatment for power plant,chemical, paper making, beverageetc industry etc.

(3) Destaining, remove organism materials for chemical plant

(4) Treatment for living water

(5) Treatment for industry water

(6) Treatment for swimming pool water

(7) Bypass filter system for recycling water

(8) Deturbidness and destaining of ground water, underground water.

Technical parameters sheet for Mechanical sand carbon filter

model | Filter diameter | straight height | Total height | water inlet-outlet | capacity | Quartz sand material | Active carbon material |

mm | mm | mm | mm | m³/hour | ton | ton | |

YL-MF-500 | 500 | 1500 | 2350 | DN32 | 2 | 0.39 | 0.11 |

YL-MF-600 | 600 | 1500 | 2380 | DN32 | 3 | 0.56 | 0.16 |

YL-MF-700 | 700 | 1500 | 2400 | DN40 | 4 | 0.76 | 0.22 |

YL-MF-800 | 800 | 1500 | 2400 | DN40 | 5 | 1 | 0.3 |

YL-MF-900 | 900 | 1500 | 2500 | DN50 | 6 | 1.3 | 0.36 |

YL-MF-1000 | 1000 | 1500 | 2600 | DN50 | 8 | 1.6 | 0.45 |

YL-MF-1200 | 1200 | 1500 | 2700 | DN65 | 11 | 2.3 | 0.65 |

YL-MF-1400 | 1400 | 1500 | 2800 | DN65 | 15 | 3 | 0.86 |

YL-MF-1500 | 1500 | 1500 | 2850 | DN65 | 18 | 3.5 | 1 |

YL-MF-1600 | 1600 | 1500 | 2900 | DN80 | 20 | 4 | 1.2 |

YL-MF-1800 | 1800 | 1500 | 3000 | DN80 | 25 | 5 | 1.5 |

YL-MF-2000 | 2000 | 1500 | 3100 | DN100 | 30 | 6 | 1.8 |

YL-MF-2200 | 2200 | 1500 | 3180 | DN100 | 38 | 7.5 | 2.2 |

YL-MF-2400 | 2400 | 1500 | 3330 | DN100 | 45 | 9 | 2.5 |

YL-MF-2500 | 2500 | 1500 | 3380 | DN100 | 50 | 9.7 | 2.8 |

YL-MF-2600 | 2600 | 1500 | 3430 | DN125 | 55 | 10 | 3 |

YL-MF-2800 | 2800 | 1500 | 3530 | DN125 | 60 | 12.5 | 3.5 |

YL-MF-3000 | 3000 | 1500 | 3630 | DN125 | 70-80 | 14 | 4 |

YL-MF-3200 | 3200 | 1500 | 3730 | DN150 | 80-100 | 14 | 4.5 |

Sand filter is put into container for sea shipment

We Recommend

New Arrivals

New products from manufacturers at wholesale prices