2 part RTV silicone dispenser for adhesive epoxy silicone urethane

- Category: >>>

- Supplier: Dongguan Yiren Industry Co. Ltd.

Share on (60095940367):

Product Overview

Description

Products Description

2 part RTV silicone dispenser for adhesive epoxy silicone urethane

Keywords: liquid dispensers, dispensing robots, dispensing valves, dispensing controller, dispensing Reservoir Tanks

Details

Product Paramenters

Gauge/Mode | Y&D7200N | Y&D7300N | Y&D7400N | Y&D7500N | Y&D7600N | ||||

Working Range | 200/200/50 | 300/300/100 | 400/400/100 | 500/500/100 | 600/500/100 | ||||

Max Load Y/Z | 5kg/3kg | 11kg/6kg | |||||||

Speed X&Y/Z | 500/350 | 800/350 (mm/sec) | |||||||

Repetive Positioning Accuracy | +/-0.02mm/Axis | ||||||||

Program Capacity | Min 100 Group, 4000 points/group | ||||||||

Data Storage Type | CF Card | ||||||||

Byte | 32bit | ||||||||

Program Display | LCD | ||||||||

Motor System | Japan micro stepping motor | ||||||||

Mode of transmission | synchronous belt | X/Y Axis synchronous belt, Z Axis precision ball screw | |||||||

Interpolation Function | 3 Axis | ||||||||

Teaching Method | Teach Pendant | ||||||||

I/O Signals Port | 8 Inputs/ 8 Outputs | ||||||||

External Control | RS232 | ||||||||

Power Supply | AC100-230V 300W | ||||||||

Working Temperature | 10-40℃ | ||||||||

Working Relative Humidity | 20-90% no condensation | ||||||||

Dimensions (mm) | 385*380*500 | 485*505*610 | 585*610*610 | 685*700*610 | 785*700*610 | ||||

Robot Weight | 23kg | 34kg | 41kg | 52kg | 56kg | ||||

Applied glue or liquid

Silica gel, EMI conductive adhesive, UV glue, AG glue, Fast dry glue, epoxy adhesive, sealant, hot glue, grease, silver glue, red glue, solder paste, cooling paste, prevent solder paste, transparent lacquer, screw fixation agent, epoxy resin, instant glue, thermal compound, anti-solder paste, paint, etc.

Applied Industry

Wireless communication, electronics, semi-conductor, automobile, medical machinery, chemical industry, artware, etc.

The stainless steel pressure tank

1)The barrel body and lid are made of stainless steel so that not prone to react with chemical substances and not easy to deform

2)Surface polishing, good sealing, applied to general liquid.

3)Equipped with the safety valve of automatic pressure relief device, high- pressure resistance

4)When using, you can directly put the original package of glue into the barrel, and no need to clean after using, easy to maintain.

5)If you demand other specifications, please consult us in advances.

Application Range

Automobile mechanical parts coating, cell phone buttons point glue, mobile phone battery packaging, laptop battery packaging, the coil point glue, PCB bonding/ sealing, IC bonding/ sealing, horn external punctuate glue, PDA sealing, LCD sealing, IC packaging, casing bonding, optical device processing, mechanical sealing, ink clip, LED, DVD, digital cameras, switches, connectors, radiators, semiconductor and other electronics, clocks, toys, medical equipment, etc.

Main Uses

1) Processing with bonding, infusion, coating, sealing, filling, drop, linear/ arc/ round gluing, etc.

2) Dispense in point, line, surface, arc, circle and irregular curve, and triaxial linkage function is available.

3) Set the amount of glue size, glue speed, glue time, stop glue time, glue stability, no glue leakage

2) Dispense in point, line, surface, arc, circle and irregular curve, and triaxial linkage function is available.

3) Set the amount of glue size, glue speed, glue time, stop glue time, glue stability, no glue leakage

4) The plate multi - jigs work in circulation, effectively improve the working efficiency

5) AB glue dispense based on 1:1

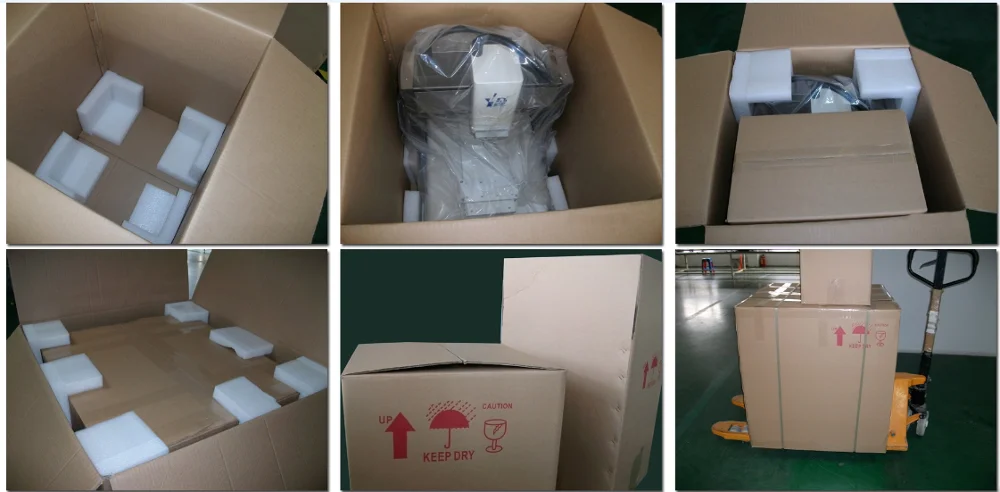

Product packaging

Package & Terms

Package: Y&D standard package.

payment:100% T/T in advance after confirm the order

Shipping:DHL/TNT&Fedex express shipment

payment:100% T/T in advance after confirm the order

Shipping:DHL/TNT&Fedex express shipment

Exhibition

We will participate in Munich Fair every year to show our products and technologies and build our own brand with all our heart.

Company Profile

Company Strenghth

We are a professional manufacturer of dispensing equipment and liquid dispenser and all the accessories. Valve, pressure tank, cartridge, barrels, tips, dispensing pen, glue gun, connect and so on. Our main product including dispensing equipment and liquid dispenser. We also have gantry conveyor robot.

Competitive Advantages

* Professionalism,creativity,advanced fluid control technology.

* Established an unshakable position in the liquid control and dispensing production.

* Highly Vertical Integration Of Manufacturing.

* Worldwide Sales

* Advanced Engineering/ Development Capability.

* Good Material Management Programs.

* Established an unshakable position in the liquid control and dispensing production.

* Highly Vertical Integration Of Manufacturing.

* Worldwide Sales

* Advanced Engineering/ Development Capability.

* Good Material Management Programs.

OEM/ODM service offered

Our product could match with other accessories (valve, tank, cartridge) according to your actual situation or as your request. We are capable to manufacture dispensing equipment and liquid dispenser according to customer's drawings or samples. We are insisting on providing top quality products with competitive price. Please feel free to contact us. Welcome your inquiry.

For more information, please feel free to contact our sales, and we will give you a quick reply as soon as we get to know it.

Our office hour

Monday to Saturday

AM 8:00-12:00 PM:13:30-17:30

Notice(Saturday we only work on half day)

Yan Zhong

Phone:86-769-85705386

Wechat: 15015488307

Phone:86-769-85705386

Wechat: 15015488307

Whatsapp: +86 15015488307

QQ:2850687512

QQ:2850687512

Our office hour

Monday to Saturday

AM 8:00-12:00 PM:13:30-17:30

Notice(Saturday we only work on half day)

We Recommend

New Arrivals

New products from manufacturers at wholesale prices