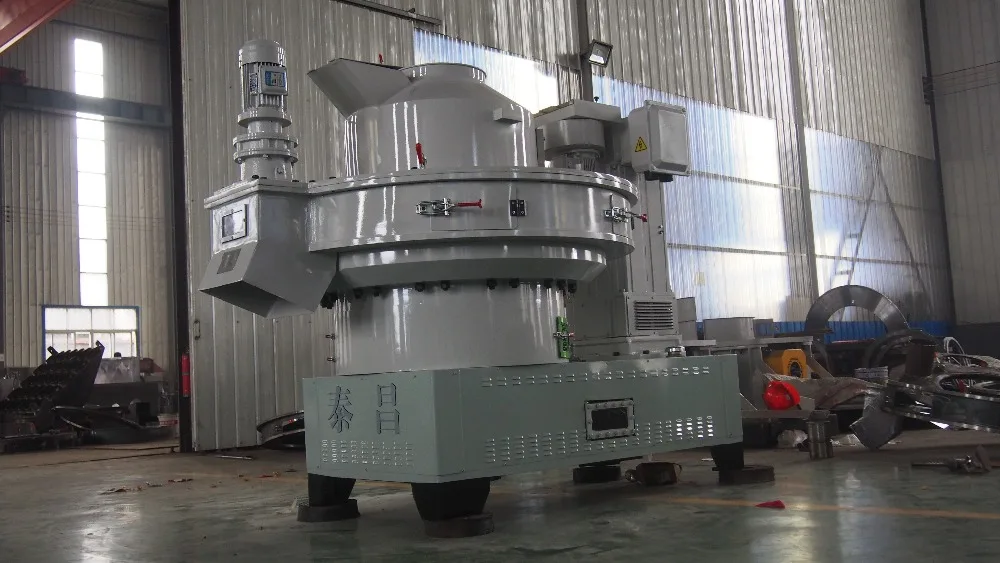

Palm/biomass/wood pellet production machine

- Category: >>>

- Supplier: Jinan Taichang Transmission Machinery Co. ltd.

Share on (60138647561):

Product Overview

Description

Palm/biomass/wood pellet production machine

Advantages of our pellet mill:

1. CE certified ISO9001 Advanced technological design requiring less labor

2. Potential for 24 hour continuous running

3. Competitive price with good quality

4. Low energy consumption and less manpower

5. Durable spare parts KAF series good quality gear box

6. Simple automated operation Stable and durable functionality

7. Easily maintained Good quality brand bearing inside of the rollers

Working process of wood pellet mill:

1.The material is transferred to the conditioner by a screw feeder, then the conditioner can make

different materials fully mixed.

2.The conditioner plays a key role in softening raw materials by utilizing water or steam.

3.After softening, the raw material is sent by a feeder to the pelletizing chamber. By spinning

rollers in the chamber force the material through the holes of the die, thus pellets are formed.

4.After pelletizing, the length of the pellet can be cut according to different user's request.

Main technical parameter of rice husk pellet making machine

Model | Power(kw) | Capacity(t/h) | Pellet Size(mm) | Weight(t) |

LKJ560 | 90/132+1.5+0.55+1.5kw | 1-1.5-2 | 6-12 | 6.1 |

LKJ700 | 132/160+1.1+1.5+0.55kw | 2-2.5-3 | 6-12 | 7 |

LKJ850 | 185/220+3+0.55+3kw | 3-3.5 | 6-12 | 8.1 |

Why Choose US

CE ISO BV certificate: basic quality guarantee.

Strong structure , our wood pellet machine body steel is bought from Jigang ,Laigang, famous factory in China.wood pellet machine 5.8t. working no rotate , safety .

Vertical hopper: This design can avoid the raw material be stuck in granulating room

Cooling system: As the pelletizing process will generate high temperature, it will lower the service life of die and bearing. Cooling system are considering this situation and avoid it happened

Double-layer dies: This design increase the efficiency of pellet making, reduce clients cost

Unique automatic lubricating system: Which lubricate the bearing, dies and rollers, increase the produce efficiency and reduce energy consumption. It can work continuous 20 hours.

After Sale Service

♥ Guarantee period is two years (except wearing parts), since the date of purchasing.

♥ 24- hour technical supports

♥ Design product according to the customers' requirement.

♥ We provide available price.

Our company

*LKJseries efficient centrifugalis wood pellet machine is our initiative patented products in China through meticulousresearch and development. The series wood pellet machine absorbs the quintessence .

At home and abroad, the heart part adopts “doublelayer die” as the unique structure; wood pellet making mahcine.

The rollers are made by abrasionproof alloy steel, improve the using life of spare parts greatly;

For the drive parts, the grease isfiltrated automatically, lubricated properly. Special design, rational

structure,low power consumption and high fficiency, sturdy and durable, and supply the gap of vertical

feeding of wood pellet making machine at home, reach to the international advanced level wood pellet machine .

Shandong jinan TaiChang transmission machinery co., LTD. Is a set design, manufacture, production

and installation of pellet production equipment, main products including biomass granule machine,

the feed grain machine, organic fertilizer granules and sawdust biomass particles, such as grinding process, the drying process, granulation process, the process of feeding, the cooling process and packing process and our leading technology in the same industry. The company is located in the

capital of shandong province, the main quthentication passed ISO9001 international quality system and the European Union CE quality quthentication.

Customer visit

Thanks for reading my information,if you have any questions, please contact me at any time.I will provide you professional service and give you a best price.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices