CN452S Wooden Case Pneumatic Air Tool Brad Framing Block Flooring Coil Nailer

- Category: Nail Guns >>>

- Supplier: Zhejiang Dongya Facility Co. Ltd.

Share on (60139120619):

Product Overview

Description

CN452S Wooden Case Pneumatic Air Tool Brad Framing Block Flooring Coil Nailer

CN452S Wooden Case Pneumatic Air Tool Brad Framing Block Flooring Coil Nailer

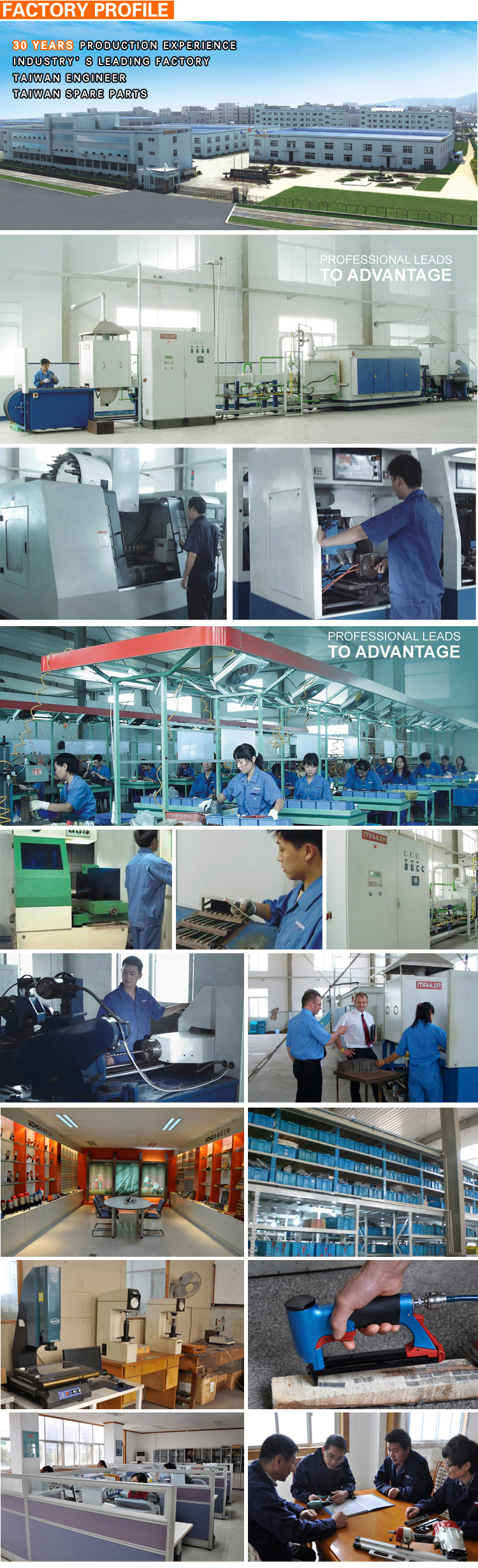

37 Year Production Experience

Industry's Leading Factory

Taiwan Engineer With 30 Years Experiences In Nail Gun Industry

Taiwan Spare Parts

SPECIFICATION

FEATURE • 360° exhaust direction • "Contact mode" safety system • "Sequential mode" can be available by changing trigger • Light die cast body of aluminum alloy • Use 15°wire or plastic collated coil nails • Depth control system • Side loading system • Easy length adjust design |

|

Parameters

| Tool Diamensions: | 248x108x260mm (9.76x4.25x10.24 in.) |

| Net Tool Weight: | 1.60kgs (3.50 lbs) |

| Operate Pressure: | 5~7Kg/cm (75~100Psi) |

| Load Capacity: | 400 Nails Wire Collated Coil Nails |

| 200 Nails Plastic Collated Coil Nails | |

| Coil Nail Angle: | 15 Degree |

| Coil Nail Diamensions: | 1.59-2.1mm(0.138-0.197") |

| Coil Nail Cap Diamensions: | 3.5-5.0 mm(0.138-0.197 ") |

| Coil Nail Spacing: | 6.0-6.8 mm (0.236-0.268”) |

Advantage

1. 800000 working times

2. All spare parts are changeable with MAX

3. Easily broken parts are imported from Taiwan

4. 100% Spare parts can be supplied to you.

5. Very powerful for hard wood

6. Both wire collated coil nail & plastic strip nails can be used.

CN452S Wooden Case Pneumatic Air Tool Brad Framing Block Flooring Coil Nailer

MAIN APPLICATION FOR Pneumatic Air Tool CN452S

SERVICE AND REPAIRS

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

| 3 | Work weakly and sluggishly | 1. Worn or damaged piston o-ring | Check and replace piston o-ring | |

| 2.Inadequate lubrication for head valve piston o-rings or too tight head valve piston o-rings | Place 2 or 6 drops of oil on o-rings or replace head valve piston o-rings | |||

| 3.Dirt in the nozzle | Check and clean the nozzle | |||

| 4 | Tool jams frequently | 1.Damaged or Worn driver (piston unit) | Check and replace driver (piston unit) | |

| 2.Damaged or Worn driver guide (nose) | Check and replace driver guide (nose) | |||

| 3.Driver guide cover is bent,so the space between driver guide cover and driver guide is too big | Check and replace driver guide cover | |||

| 5 | Nail can not be shot | 1. Driver (piston unit) can't return to the correct position. | Refer to no. 1 Symptom | |

| 2.Driver guide(nose) can not match magazine well | Check and correct the position between driver guide(nose) and magazine | |||

| 3.Worn or damaged nail pusher compression spring | Check and replace nail pusher compression spring | |||

1) 37 Years Production Experience

2) 13 Years Alibaba Gold supplier with High Reputation

3) Alibaba Trade Assurance USD308,000

4) 100% QC Inspection before Shipment

5) Engineer Team from Taiwan

6) Competitive Price

7) Lifelong After-Sale Service

8) Advanced Machines

9) CE Certificate and ISO 9001:2015

10) OEM Available

11) Sample Available

We Recommend

Hardware Cartridge Cordless Nail Gun 301T

Small manual carton packing machine hand nail stapler

New Arrivals

New products from manufacturers at wholesale prices