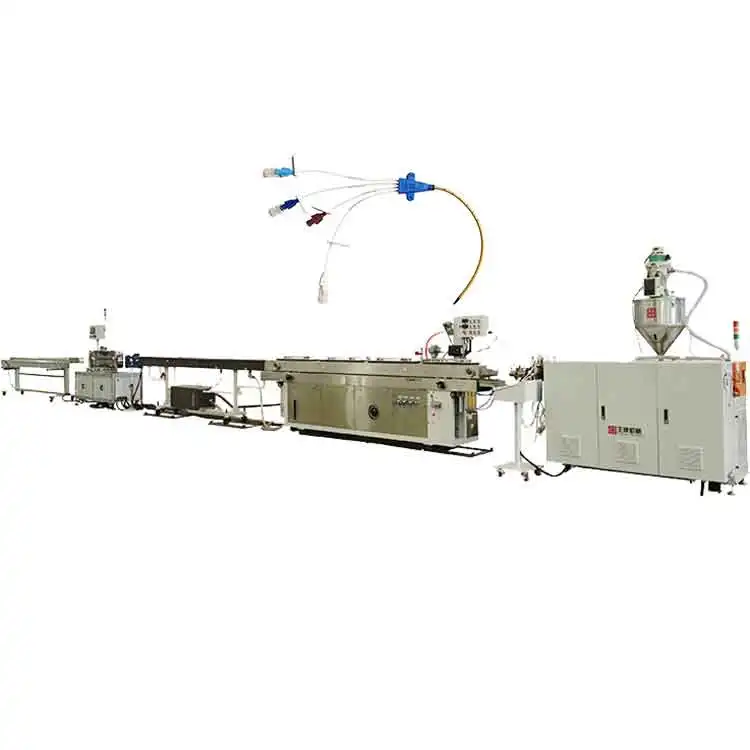

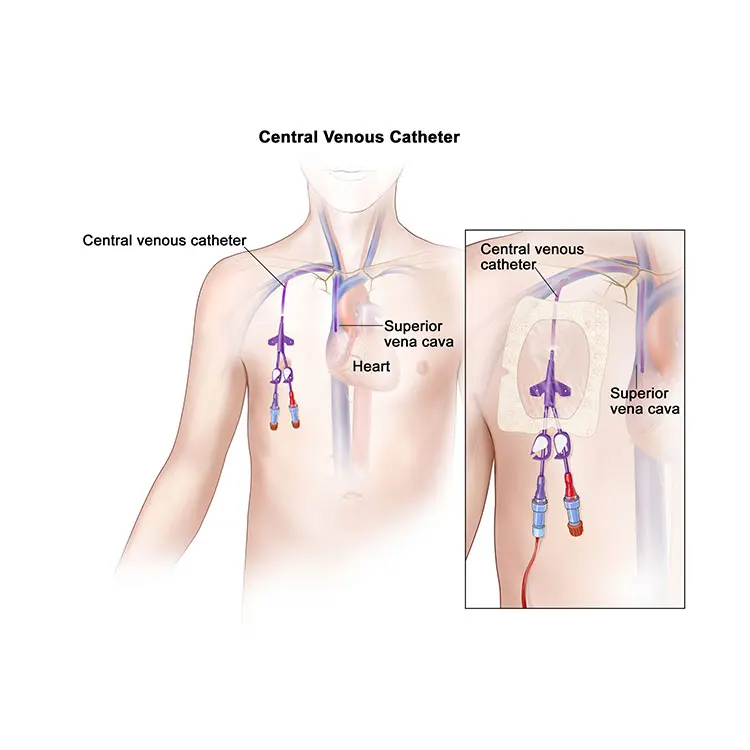

PVC MEDICAL CENTRAL VENOUS CATHETER EXTRUDER MACHINE

- Category: >>>

- Supplier: Cissco Machinery Co. Ltd.

Share on (60233743727):

Product Overview

Description

PVC Medical Central Venous Catheter Extruder

1. Equipment features of pvc tube machine:

2. Overview of pvc tube machine:

- Name and model : SXG-65 Medical tube extrusion line

- Output: Max 70 ± 10%Kg/h;

- Environment: Indoor, humidity 0.85, no condensation point, temperature ≤45℃;

- Power supply: 380V 50HZ, 3-phase 4wires; Install power ≤65KW;

- Circulation water flow: 8-10.0m3/h;

- Compressed air: 0.6-0.7Mpa, consumption appr 400L/min.

- Operation direction of production line is from right to left direction;

- Core height of production line is 1100mm;

- Install space: 22.0m x 2.0m x 2.5m (length x width x height);

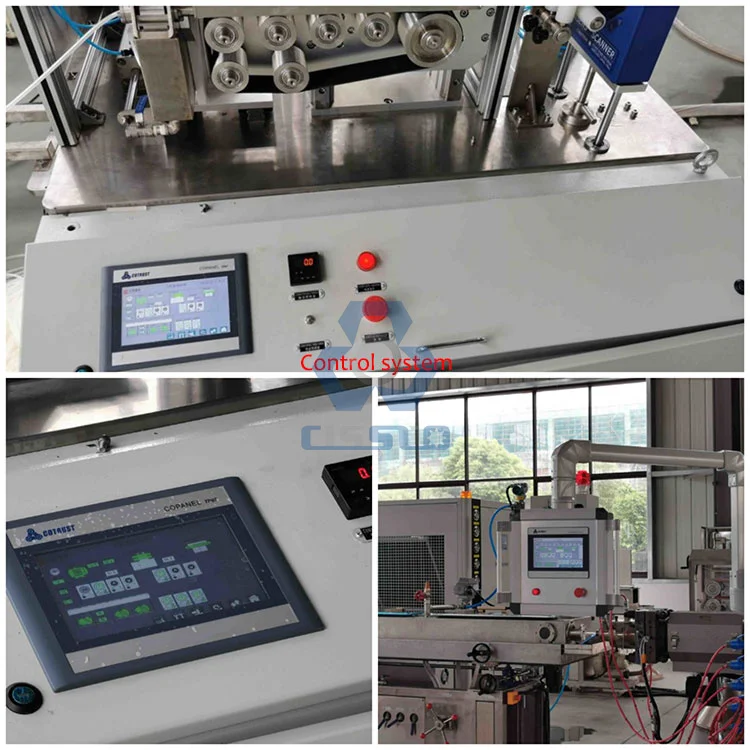

3. Configuration of pvc tube machine:

| Item. | Equipment Name | Model | QTY/set |

| 1.1 | Automatic loader | JLD30 | 1 |

| 2.1 | Single screw extruder (HMI control type) | BDSJ-65/28 | 1 |

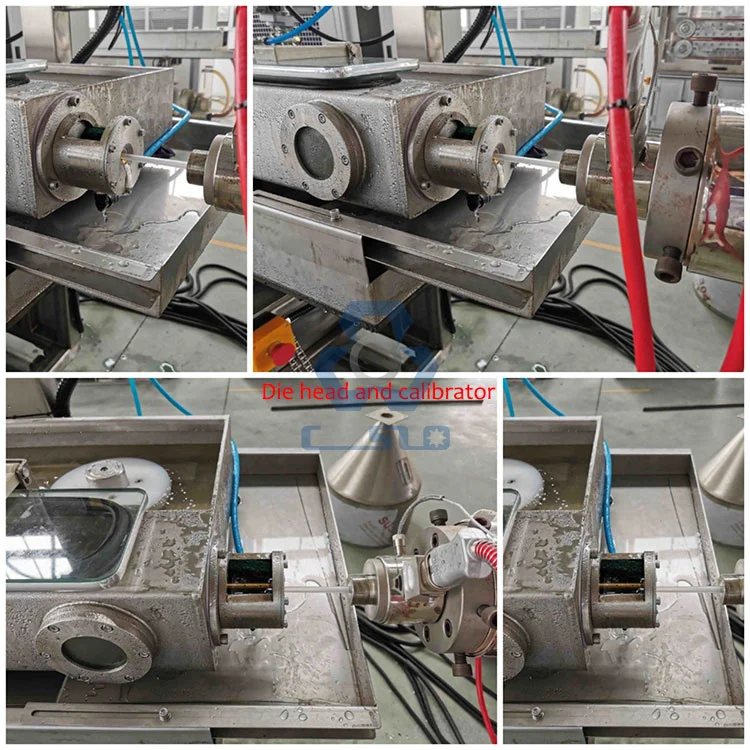

| 2.2 | Tube mold | GM-65T | 1 |

| 3.1 | Full sealing precision vacuum sizing tank | ZDX-600-3R | 1 |

| 3.2 | Cooling tank | CW-600 | 1 |

| 3.3 | Chiller (Air cooling type) | LS207F | 1 |

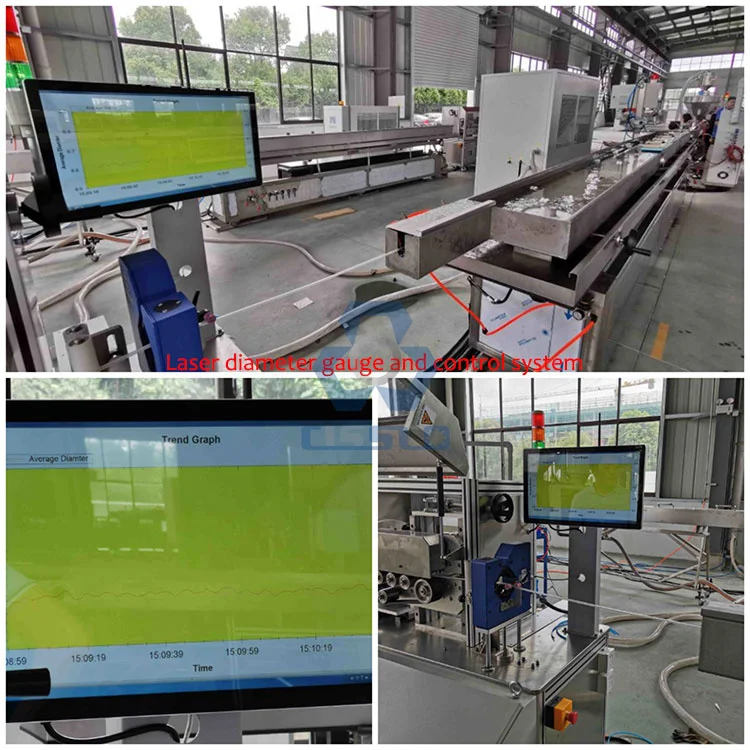

| 4 | PROTON bidirectional high speed laser diameter gauge | DG2030 | 1 |

| 5 | High speed SERVO synchronous belt puller | TKB-600H | 1 |

| 6 | Double-position claw plate winding machine | SPJ-1000ZP | 1 |

4. Pictures of pvc tube machine:

- What kind of products that you want to make? Do you have photos of tube?

- What's the size of tube?

- What's the output do you need?

- Do you have experiences in this field?

1. We design, engineer and manufacture and customized the extrusion line.

2. Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

3. Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

4. Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

CissCo Machinery Co., has been engineering and manufacturing a series of PRECISION EXTRUSION MACHINERY for more than 30 years and has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

Comparing with the low price low quality machine, please note our strong advantages:

1. 30 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services.

l Contactor: Mr. Louies Liu

l Skype: louies.cissco

l Cellphone/Whatsapp/WeChat: +86 18917527205

l Web: www.cisscomachinery.com

l Add: No. 58, New Jinqiao Road, Pudong, Shanghai, China

We Recommend

New Arrivals

New products from manufacturers at wholesale prices