Stencil printer Automatic PCB printing machine solder paste printer

- Category: >>>

- Supplier: Shenzhen Grandseed Technology Development Co. Ltd.

Share on (60236457625):

Product Overview

Description

Automatic PCB printing machine solder paste printer

Our advantages:

- Production advantages: mass production,assembly line work

- Management advantages: simplification of procedures, standard operation

- Procurement Advantages: all the accessories supplied by the manufactures directly.

- Delivery advantages: supply with stock.

- Durability advantages: free warranty for one year, three years free of labor costs, maintenance of life;

- Service advantages: quickly response, on call 24 hours a day

Performance Advantages:

Performance Test | Traditional | Energy-saving Type |

Energy saving | 8°/H | 5°/H |

Time saving | 20min/start | 15min/start |

Low noise | 80db | 60db |

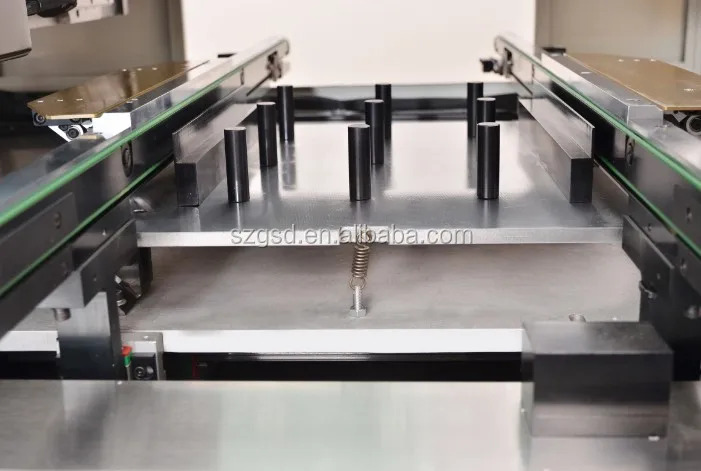

Deatails of The Machine:

Specifications:

Items | Specifications |

Screen Frame Dimension | Min Size: 420*500 mm Max Size: 1500*900 mm Thickness: 25~40 mm |

PCB Min Size | 120*50 mm |

PCB Max Size | 1200*300 mm |

PCB Thickness | 0.8~6 mm |

PCB Warpage | Max: PCB Corner Sealing Line 2% |

Transport Height | 900±40 mm |

Transport Direction | L to R/ R to L/ L to L/ R to R |

Transport Speed | Max: 1200 mm/ s adjustable |

PCB Positioning | Supporting Style: Magnetic center/ Up-down table adjusted by hands Clamping Style: Particular top pressing, side clamping,vacuum adsorbing

|

Print Head | 2 independent motorized print heads |

Scarpers Speed | 6~300mm/s |

Scrapers Pressure | 0~10kg/ cm² |

Scrapers Angle | 55°(Standard) |

Scrapers Type | Stainless Steel (Standard), Plastic |

Stencil Separation Speed | 0.1~20mm/ sec Programmable |

Cleaning Style | Dry, wet, vacuum (programmable) |

Table Adjustment Ranges | X: ±10mm Y:±10mm θ:±2° |

Repeat Position Accuracy | ± 0.01 mm |

Printing Accuracy | ± 0.025 mm |

Cycle Time | < 13s (Exclude Printing & Cleaning) |

Product Changeover | < 5 min |

Air Pressure Requirement | 4.5~6 kg/ cm² |

Power Input | AC: 220±10%,50/60HZ, 1~3kw |

Control Method | PC Control |

Machine Dimensions | 2000(L)* 1364(W)*1440(H) mm |

Machine Weight | Approx: 1000 kg |

PCB Transport Over-plate Height | 35 mm |

Machine Features

(1) The adoption of Japanese precision motors and linear guide rails better stabilize the base of printing scrapers.

(2) The printing pressure of the double scrapers respectively uses the upper and lower cylinder precision throttle valve behind to set the speed of the scrapers up and down, and effectively avoid resonance.

(3) The printing base can be lifted up to 45° and fixed, and scrapers can be mounted and dismounted and steel nets cleaned as well.

(4) The printing base can be moved forward and fixed to adapt to the position of the steel plate samples so as to make better printing results.

(5) The scrapers on the printing base can be set by adjusting nuts up and down.

(6) The spacing of the printing bed-plate and steel nets is level, and can also be fine-tuned with digital scales for reference.

(7) The machine arm can be adjusted left and right respectively, maximum PCB size can be printed: 1200×300.

(8) The combined printing bed-plates with grooves and positioning PIN are easy to set and change for single substrate and double-sided substrate operation.

(9) The editing means uses the arm (steel nets) to move to match up with the printed materials (bed-plate) X, Y, Z, for adjustments, easy and quick.

(10) Electric actions by microcomputer PLC control, man-machine interface, and touch control, operators can choose single/double time scrapings or automatic and manual operations.

Patents of the Machine

Appearance Patent | Patent Right Code: 201410387489.2 |

Lifting System | Patent Right Code: 201420145549.5 |

Stencil Clamping System

| Patent Right Code: 201420227188.9 |

Guide Rail Transport System

| Patent Right Code: 2014120227460.3 |

Mark Image Recognition System

| Patent Right Code: 201410121005.X |

Automatic Cleaning System

| Patent Right Code: 201420444485.9 |

Suspension-type Scraper System

| Patent Right Code: 201420229924.4 |

Platform Correction System

| Patent Right Code: 201430289406.7 |

Overall Invention of the machine

| Patent Right Code: 201420229970.4 |

Certificates and Customers

Our company

GrandSeed is mainly specialize in electronic automatic equipment including wave soldering machine, reflow oven, LED mounter, automatic printer along with variety of electronic production lines such as assembly line, aging line, transmission line and it’s associated equipment.

GrandSeed is aim to provide Chinese made automatic equipment and solutions to the entire world. As we have built close relationship with corresponding manufactures from upstream to downstream of the industry, one-stop solutions are able to be provided to fulfill customer needs. “Professional produces Reliable” it is our faith that is leading us to be extraordinary.

Grandseed headquater in Shenzhen

Grandseed Factory in Anhui province

1.How many years our company in SMT industry?

Reply:our company has established more than 17 years,since 2002,We started to develop and produce SMT machines.

2.How the market?

Reply:we have mature domestic and foreign markets. Overseas, our products have been sold to more than 60 countries.

3.How about the warranty and service?

Reply:The whole machine is guaranteed for one year, and any problems within one year are repaired free of charge. Purchase and send accessories and maintenance tools, provide free installation and training operations (applicable to domestic and foreign customers)

4.If we have patent or mature technology?we are manufacturer or trade company?

Reply:We are a company that integrates R & D, production and sales, and has many invention patents so far.

Laboratory room

We Recommend

New Arrivals

New products from manufacturers at wholesale prices