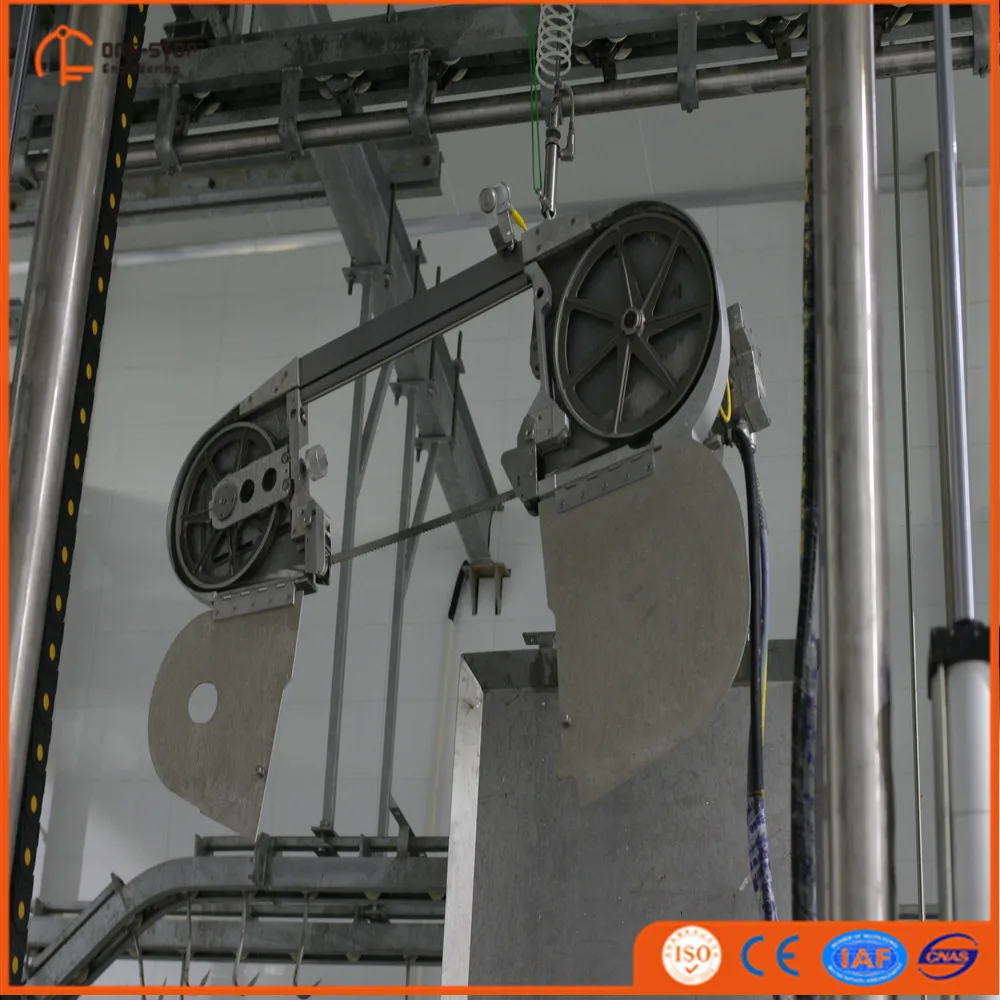

Cattle /cow half carcass splitting saw Band type splitting saw for cattle slaughterhouse equipment

- Category: >>>

- Supplier: Shanghai One-Stop Engineering Co. Ltd.

Share on (60238181105):

Product Overview

Description

Picture:

Feature:

- Easy operation

- Simple structure

- Good quality

- Low price

- High hygiene standard

Choose Onestop ,choose the success!

The complete slaughter flow diagram include as flowing:

Cattle slaughter line (As per Islamic method)

Cattle slaughter line products:

- Halal slaughter box Evisceration chute

- Landing grate Carcass splitting system

- lifting hoist Doctor's inspection platform

- Bleeding line Trimming washing platform

- Leg changing system Quartering station

- Dressing line De-boning hall & chiller

- Head conveyor Accessories & additional platform

- Hide puller

Scheme of working sequence:

A.Animal race,animal halal point and lifting of the animal

B.Bleeding of the animal in hanging position and severing fore-feet and horns

C.Transfer severing 1st foot and pre-dehide leg,insert hook in transferring conveyor

D.Severing 2nd foot and pre-dehide leg,insert hook in sinew and in transferring conveyor

E.Anal bung removing splitting aitch bone

F.Front hide opening abdominal side and pre-dehide for legs.

G.Twine for final automatic dehiding of carcass from up and down

H.Hanging head on lifting arm of head and red offal conveyor and automatic bringing to Dr.inspection platform

I.Brisket opening for viscera removal preparation

J.Opening of abdominal side,remove vesicle and genitals,take out paunch and intestines,disengage and esophagus.

K.Halving carcass with fully automatic splitting installation

L.Red offal and animal head doctors inspection

M.Carcass inspection and stamping

N.Trimming

O.Carcass washing and dripping

P.Weighing and classifying

Choose Onestop ,choose the success!

The complete slaughter flowchart include flowing equipment:

I.Double rotary halal/Kosher knocking box

- Double rotary type killing box(As per Islamic method)

- Pneumatic/ hydrolic controlled doors

- Motorized rotation

- Hot dip galvanized structure

- Customized box sizes as per requirements

- Stainless steel(ss 304)

- Speed 100 heads per hour

- Single rotary type killing box(As per Islamic method)

- Pneumatic /Hydrolic controlled doors

- Motorized rotation

- Hot dip galvanized structure

- Customized box sizes as per requirements

- Stainless steel(ss 304)

- Speed 45 heads per hour

- Stainless steel 304 grade landing grate for smooth animal landing after slaughter

- Hot dip ga;vanized landing grate for smooth animal landing after slaughter

- Lifting hoist is a quick mechanized system to lift and guide the slaughtered animal to an automatic continuous bleeding conveyor

- Heavy duty motorized lifting and descending system

- Pneumatic pressing system

- Sequence system is used for disciplined sequence of animal slaughter to the bleeding line.

- Hot dip galvanized structure where the entire bleeding of the animal takes place.

- Motorized line 100*12 flat rail.

- Electric stimulator is used to allow complete bleeding of the animal on the bleeding line.

- It has quick pneumatic interchange system from bleeding line to dressing line for further animal processing

- This machine greatly reduces the human labor and improves productivity reaching it's maximum speed at 100 animals per hour

- It is one of our indispensable systems of slaughter house machinery

- Hot dip galvanized structure

- Pneumatic leg changing system(From bleeding line to dressing line)

- Motorized conveyor 75*12 flat rail

- Sensor controlled carcass movement

- Fixed platforms for hind(upper back)part preparation

- Fixed / mobile platforms for fore (front) part preparation

- Hot dip galvanized frame work with custom designed chain

- Stainless steel hooks with integral hook sterilization system

- 5hp gear motor

- Hide puller is bulit for both strength and speed.This machine has a capacity of up to 80-100 heads per hour.The hide is pulled off clearly and efficiently from the carcass without any damage.Uniform hide is preferred by tanners and hide processors

- Our unique design product comes complete with hydraulic motor,cylinder,valves,pull chain,S.S revolving roller galvanized framework,hide chute and two S.S platforms for butchers to perfrom trimming with special knives so that there is no chance for either carcass or hide to get damaged during the process delivering high quality.We have a new addition to our product list,the electro pneumatic hide puller made for capacity up to 40-50 heads per hour

- The stainless steel rotary drum is attached with two stainless steel puller chains

- The entire assembly goes down by a hydraulic / pneumatic cylinder of 125mm bore and 2000mm strokes

- The drum motion is controlled by low voltage electric controls.

- The hyaraulic system is powered by 50hp hydraulic power pack

IX. Viscera chute & conveyor

- Evisceration machinery are of two types pneumatic viscera chute and viscera conveyor for the removel of white offal from the animal carcass for further processing.

- Custom designed fixed platform is available for pneumatic viscera chute and viscera conveyor

- Pneumatic controlled sequence system of viscera inspection

- Aluminium checked plate stainless steel platform with stainless steel railing

- Two hydraulic/single pneumatic cylinders foot valve operated

- The hydraulic system is powered by 5hp hydraulic power pack

I. Doctor's inspection platform

There are 3 different kinds of dotor inspection platform

- Carcass inspection platform

- viscera inspection platform

- Head inspection platform

- Pneumatic platform for complete inspection of the carcass

- Fixed doctors inspection platform for viscera

- Fixed doctors inspection platform for head and offal

III.Quartering station

At the quartering station the half carcass is further split into two more pieces hence the term quartering.From this point the carcass moved to the chillers and for further processing at the deboning area.

IV.De-boning hall &chiller

The chiller and de-boning line structure is hot dip galvanized available in two types.

- Motorized de-boning line

- Motorized chiller line

- Manual chiller and de-boning conveyor

I.The minimum order

1pcs

II.Payment item

Onestop always produce all equipment from spare parts to complete machine in one factory, so that we can control quality of all facilities and reduce cost of complete machine, then we can supply high quality equipment with better price than other competitors

Payment item we can accept.L/C,D/P,TT,etc.

III.Delivery time

15-30days after order (According to the customer order,we will arrange it for customer)

IV.After sale service

1 year maintaining time, we will arrange the technical workers to do it.

Introuction

Onestop,an enterprise with turnkey projects has more than 20 years contracting experience ,

is the unique professional enterprise that underta pig,cow,sheep poultry butchery in china.

Company structure:

The company can produce slaughtering equipments,waste water treatment,refrigeration equipment,

heat insulator,stainless steel products and stainless steel construction by own,with four factories specializing in machinery and one specializing in stainless steel construction .

Core advantages:

Our,company,provides,onestop,service,including,professional,consultation,design,construction,production ,

instalation,training,matinence,etc .It can avoid errors during the program construction and it is time saving ,money saving ,labor saving

Achievements:

The butchery we undertake covers about 50 nationes all around the world ,including Russia, Mongolia, Japan,

Indonesia, Pakistan, India, Iran, The United Arab Emirates, the United States, Brazil, Venezuela, Latvia, Austra lia, Ethiopia, Tanzania, Nigeria Angola ect . And some agencies are established in South Africa, Africa, Southeast Asia, Russia, Japan and other regions.Therefore ,we can provide the convenient services for you!

- The livestock abattoir (slaughter)layout designing and proposal drafting.

- The livestock abattoir (slaughter)facilities producing.

- The livestock abattoir (slaughter)facilities international shipment.

- The livestock abattoir (slaughter)facilities installation and debugging.

- The livestock abattoir (slaughter)equipment operator training.

- The livestock abattoir (slaughter)facilities periodic inspection.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices