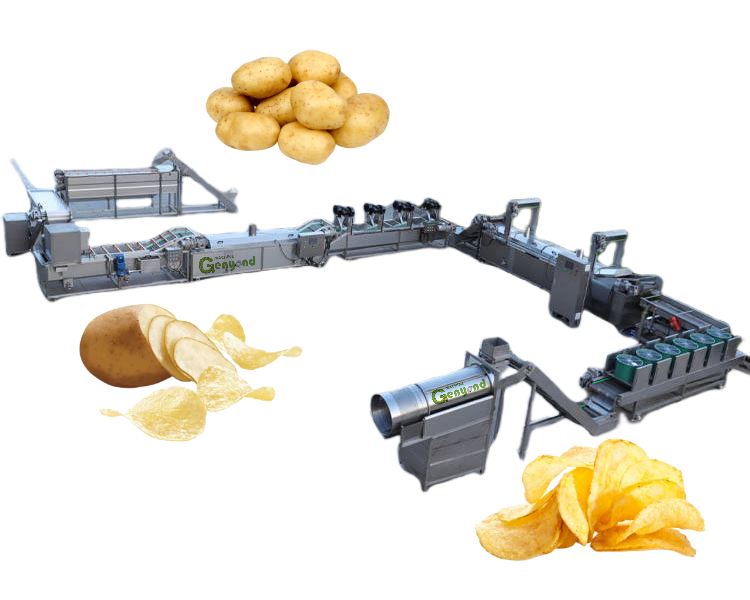

Excellent quality full automatic potato chips production line/fresh potato chips making machine/frozen french fries

- Category: >>>

- Supplier: Shanghai Genyond Technology Co. Ltd.

Share on (60356344779):

Product Overview

Description

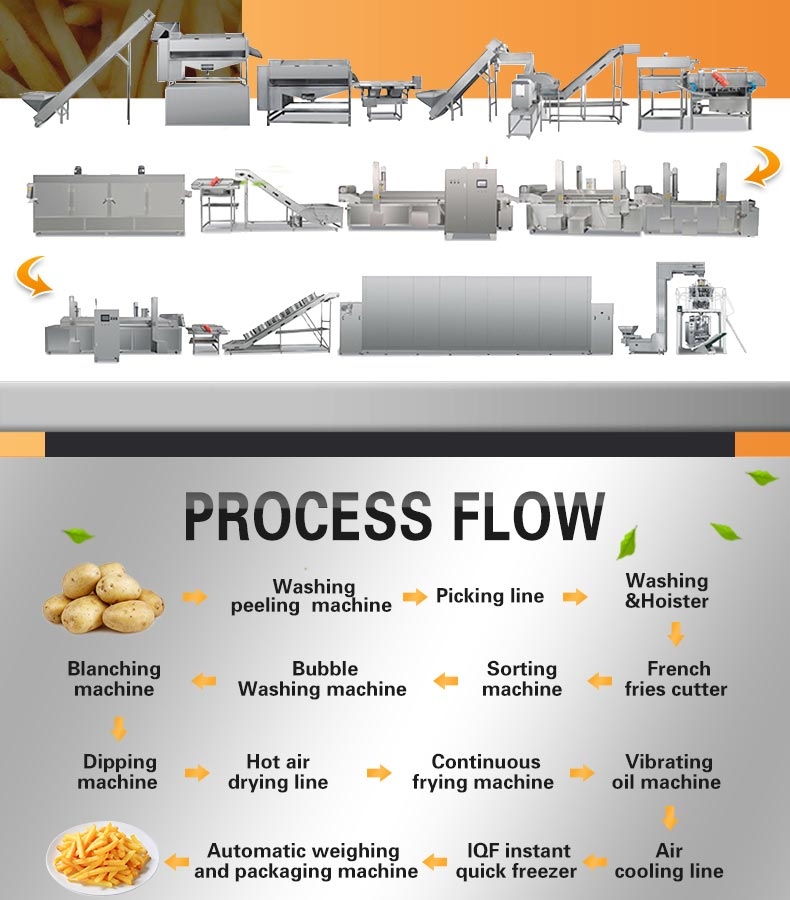

3. Heating method: Electric heating, Gas heating or Diesel heating (equipped with RIELLO or BALTUR burner), etc.

4. The size of French fries and the thickness of potato chips are adjustable. french fry production line

5. For French fries line, we have special equipment to remove the unqualified fries. french fry production line

6. With special designed fryer, quick heating and energy saving, enabled good performance. french fry production line

Chips weighting packing machine | Vacuum fryer machine | Plantain/banana chips production line

|

| Brush peelling machine | STEAM PEELING MACHINE |

GENYOND MACHINERY INDUSTRIAL GROUP

It has 6 factories in China for food machine and packing machine.

Shanghai Genyond Technology Co Ltd; Zhangjiagang Genyond Machinery Co Ltd

Shanghai Jou Yu industrial Co Ltd; Shanghai Keyfood Machinery Co Ltd

Sino topone machinery; Nantong Yihai Machinery; Kunshan Kpack Machinery

Our products have been exported to more than 160 countries with Annual sales reaching 80 millions in 2022 and it raises by yearly average 10% above.

Genyond machine has more than 100 engineers for the installation of oversea projects.

You just need to give us your idea on final product to be made, processing capacity, way of packing, we will make the proposals for your checking. You can also give us your budget, we can also design a line to meet your budget accordingly.

A satisfying project will be given; A long-term cooperation will come.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices